Material drying unit

A material and unit technology, used in dryers, drying, drying of solid materials, etc., can solve problems affecting the quality of materials to be dried, and achieve the effects of long drying time, avoidance of breakage, and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

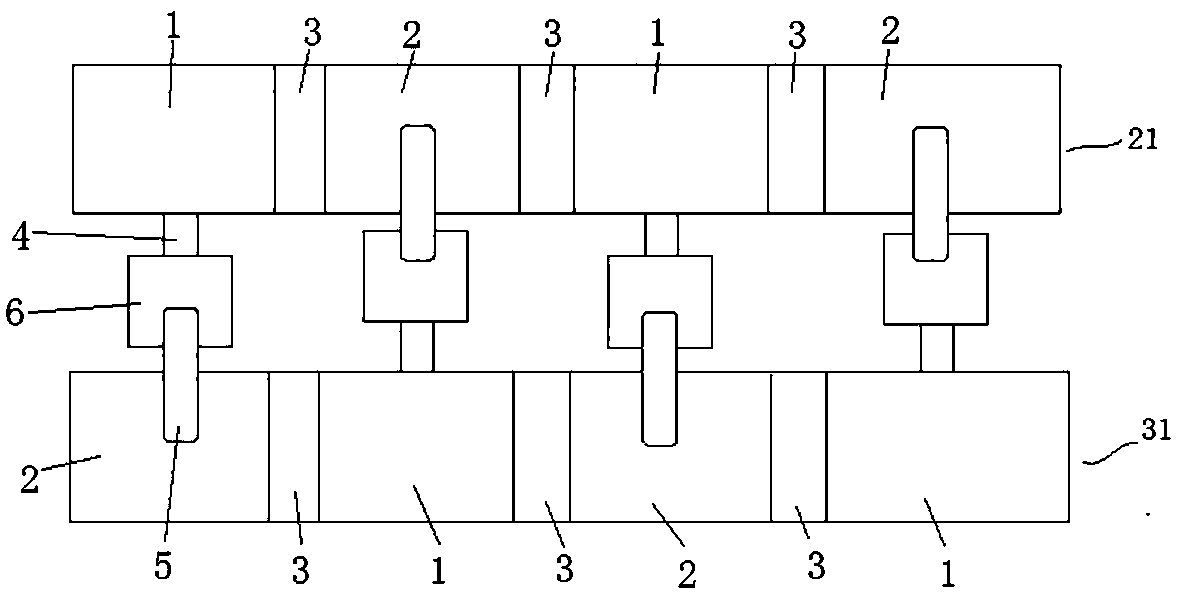

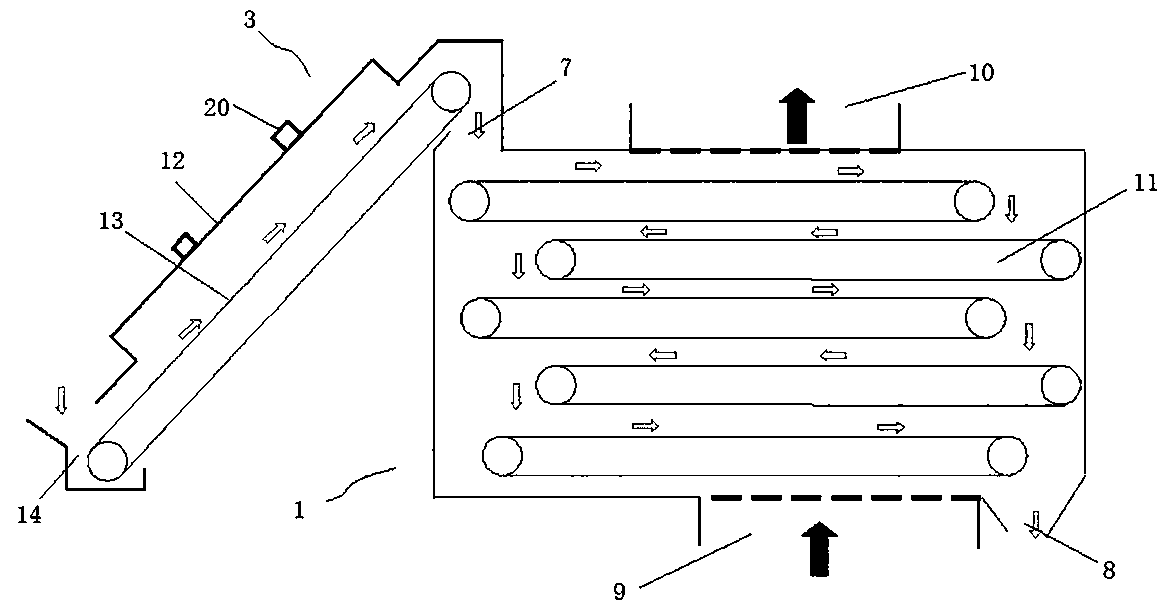

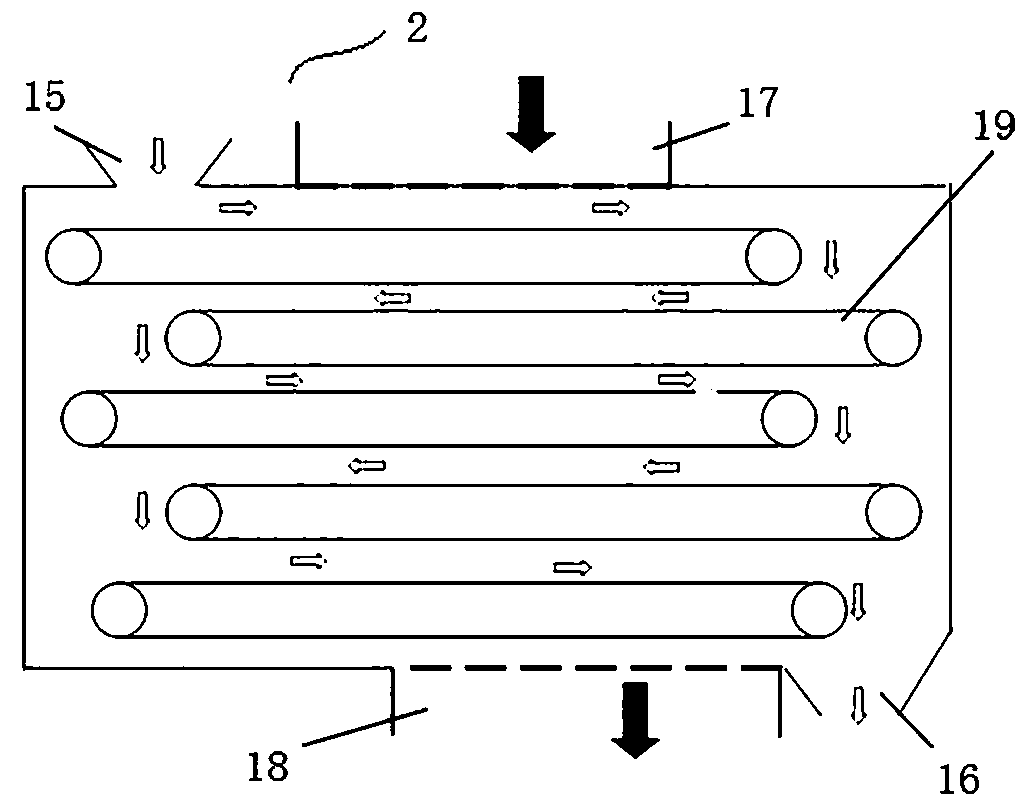

[0035] Such as figure 1 As shown, the material drying unit includes a hot air drying area 1 and a cold air drying area 2. The hot air drying area 1 dries the material through the hot air, and the cold air drying area 2 dries the material through the cold air. The hot air drying area 1 and the cold air drying area 2 are both There are more than two places, the hot air drying area 1 and the cold air drying area 2 are alternately arranged for the materials to be dried to pass through the hot air drying area 1 and the cold air drying area 2 alternately.

[0036] In this embodiment, a slow zone 3 is provided between the hot air drying area 1 and the cold air drying area 2, so as to avoid mutual influence between the hot air drying area 1 and the cold air drying area 2, and also to facilitate the transportation of materials.

[0037] Such as figure 1 As shown, the material drying unit includes two drying lines, which are respectively the first drying line 21 and the second drying l...

Embodiment 2

[0049] The difference with embodiment 1 is that the lifting conveyor belt in the specific embodiment 1 is not set in the hot air drying area and the cold air drying area, but the conveyor belt conveyed along the horizontal direction is set on the drying line, and the length of the conveyor belt is greater than Corresponding to the length of the drying line, there are three areas on the conveyor belt corresponding to the hot air drying area, slow drying area and cold air drying area. Every time the conveyor belt travels the length of a zone, it needs to stay for a period of time to dry and slow the material.

Embodiment 3

[0051] The difference from Embodiment 1 is that the cold end of a heat pump corresponds to more than two cold air drying areas, and at this time, more than two pipelines need to be drawn from the cold end to correspond to each cold air drying area; or the cold end of a heat pump The hot end corresponds to more than two hot air drying areas. At this time, the hot end needs to lead out more than two pipelines to correspond to each hot air drying area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com