Short exploration blowout hole prevention equipment

A kind of equipment and blowout prevention technology, applied in mining equipment, gas discharge, safety devices, etc., can solve problems such as safety hazards, gas gushing, and gas gushing volume increasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

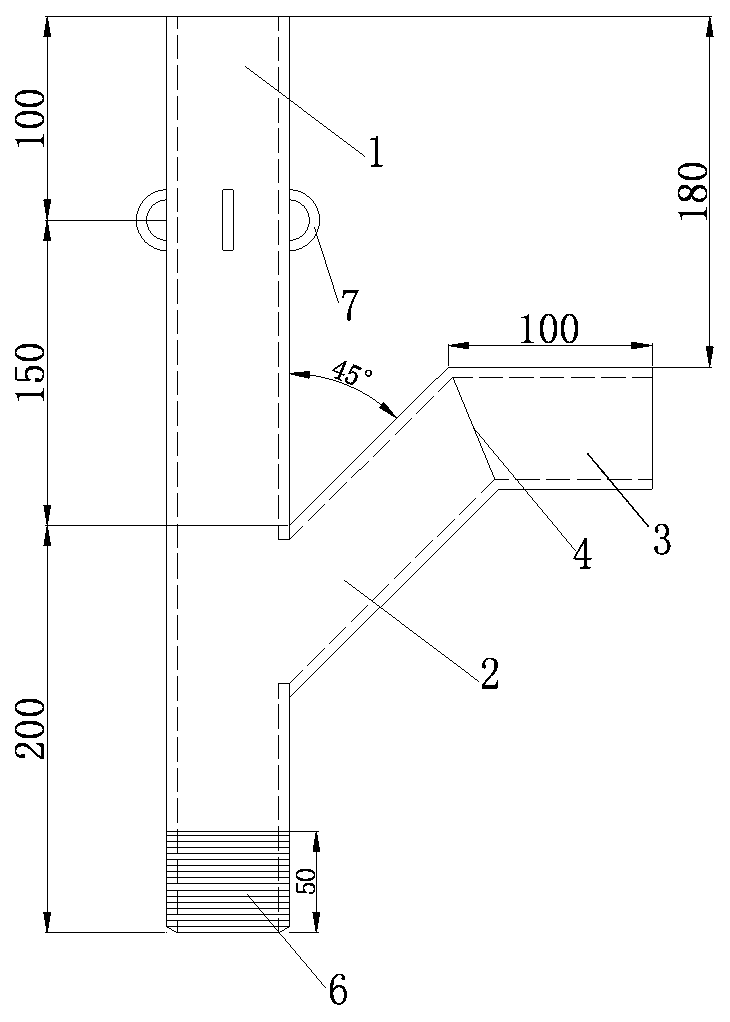

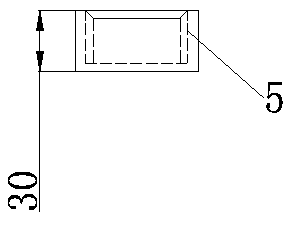

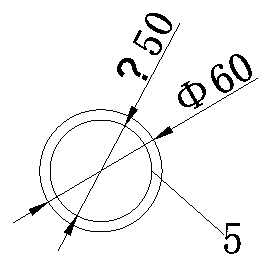

[0016] Example: see figure 1 , figure 2 and image 3 , in the figure, 1-main pipe, 2-secondary pipe, 3-connecting pipe, 4-filter, 5-plug, 6-thread, 7-copper ring.

[0017] The short detection blowout prevention equipment includes pipelines. The pipelines include a main pipeline 1 and an auxiliary pipeline 2. The main pipeline 1 is vertically arranged, and the auxiliary pipeline 2 is arranged obliquely on the main pipeline 1, and the two are in a Y-shaped structure. The auxiliary pipeline 2 A connecting pipe 3 perpendicular to the vertical direction of the main pipe 1 is arranged at the port, and a filter screen 4 is arranged at the connection between the connecting pipe 3 and the auxiliary pipe 2 .

[0018] Further, the included angle between the main pipeline 1 and the auxiliary pipeline 2 is 45 degrees, and the main pipeline 1 is provided with a plug 5 (the outer diameter of the plug is 60mm, and the inner diameter is 50mm), and the plug 5 is set on the main pipeline 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com