Method for detecting visual casing breaking water outlet point under nitrogen gas lift well

A detection method and water point technology, which can be used to detect the appearance of fluid at the leakage point, measurement, earthwork drilling and other directions, which can solve the problems of harsh detection conditions, inability to determine the leakage point, and inability to observe the leakage point of the casing. , to achieve the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

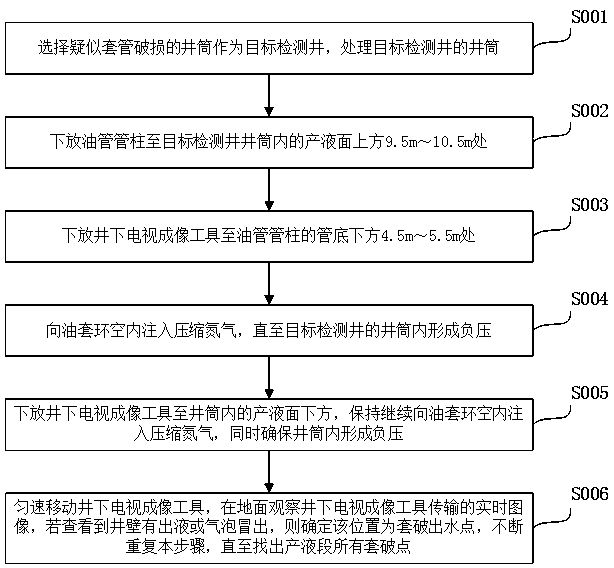

[0042] refer to figure 1 , the first embodiment of the present invention relates to a nitrogen gas lift downhole visual casing break water point detection method, comprising the following steps:

[0043] S001. Select the wellbore suspected of casing damage as the target detection well, and process the wellbore of the target detection well;

[0044] S002. Lowering the tubing string to a place 9.5m to 10.5m above the liquid production level in the wellbore of the target detection well;

[0045] S003. Lowering the downhole television imaging tool to a place 4.5m to 5.5m below the bottom of the tubing string;

[0046] S004. Injecting compressed nitrogen gas into the annulus of the oil casing until a negative pressure is formed in the wellbore of the target detection well;

[0047] S005. Deploy the downhole TV imaging tool to below the liquid production surface in the wellbore of the target detection well, keep injecting compressed nitrogen into the annulus of the oil casing, and...

no. 2 approach

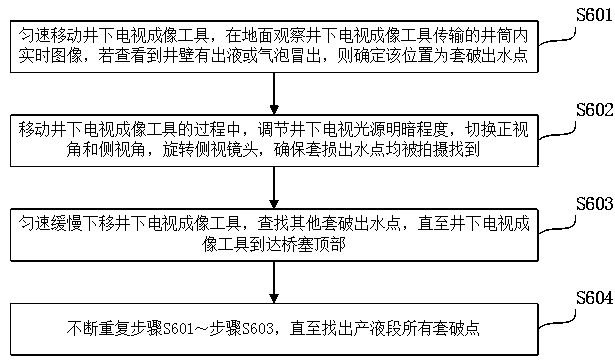

[0054] refer to figure 1 , this embodiment relates to a nitrogen gas lift downhole visualization casing break water point detection method, including the following steps:

[0055] S001. Select the wellbore suspected of casing damage as the target detection well, and process the wellbore of the target detection well;

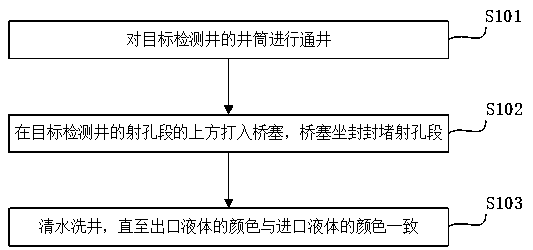

[0056] refer to figure 2 , step S001 specifically includes the following:

[0057] S101. Drilling the wellbore of the target detection well;

[0058] S102. Drive a bridge plug above the perforation section of the target detection well, and set the bridge plug to seal the perforation section;

[0059] S103. Wash the well with clean water until the color of the outlet liquid is consistent with the color of the inlet liquid.

[0060] S002. Lowering the tubing string to a place 9.5m to 10.5m above the liquid production level in the wellbore of the target detection well;

[0061] S003. Lowering the downhole television imaging tool to a place 4.5m to 5.5m below t...

no. 3 approach

[0068] On the basis of the first embodiment, in the step S002, a tubing string with a horn head is selected as the string to be run into the wellbore of the target detection well.

[0069] The reason why the tubing string with a trumpet head is chosen as the tubing string to be lowered into the wellbore of the target detection well instead of the ordinary tubing is to facilitate the salvage of TV tools. If there is no horn head, the TV tool is easy to scratch the tubing .

[0070] As a preference, in the step S002, the tubing string with the trumpet head is lowered to 10 m above the liquid production level in the wellbore of the target detection well.

[0071] As a preference, in the step S003, the downhole television imaging tool is lowered to 5 m below the bottom of the tubing string.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com