Soluble toe end sliding sleeve for well cementation and well completion and use method thereof

A toe-end, cementing technology, applied in wellbore/well components, wellbore/well valve device, earth-moving drilling and other directions, can solve the problems of uncontrollable stability, complicated operation, tool wall thickness, etc. It is difficult to establish the liquid flow channel, simplify the tool structure, and improve the success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

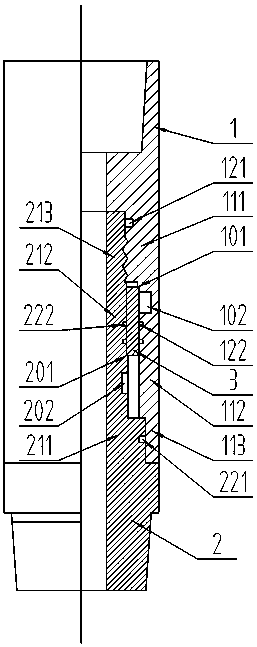

[0035] Referring to Fig. 1, it is a schematic structural diagram of Embodiment 1 of the present invention, a soluble toe-end sliding sleeve for cementing and completion, which is characterized in that it includes:

[0036] An upper joint 1, the upper joint 1 has a through hole 1 in the axial direction;

[0037] The lower joint 2, the upper end of the lower joint 2 is inserted into the upper joint 1, the overlapping surface of the lower joint 2 and the upper joint 1 forms an annular cavity, the inner axis of the lower joint 2 has a through hole 2, and the upper joint 1 The inner wall surface and the outer wall surface of the lower joint 2 are respectively located in the annular cavity to have a first groove 102 and a second groove 202, and the distance between the inner bottom surface of the first groove 102 and the outer wall surface of the upper joint 1 is smaller than that of the second groove. The distance between the inner bottom surface of the groove 202 and the inner wal...

Embodiment 2

[0043] Referring to Figure 1: the top end of the upper joint 1 has an internal tapered thread.

[0044] In actual use: the upper joint 1 is connected to the staged fracturing tool string through the inner tapered thread, and the inner tapered thread of the upper joint 1 is convenient for connecting with other tools.

Embodiment 3

[0046] Referring to Figure 1: the bottom end of the lower joint 2 has an external tapered thread.

[0047] In actual use: the outer taper thread of the lower joint 2 is connected with the bumper short connection thread, and the outer taper thread of the lower joint 2 is convenient for connecting with other tools.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com