Drainage asphalt pavement pre-maintenance material and construction process thereof

A technology of drainage asphalt and construction technology, which is applied in the field of drainage asphalt pavement pre-maintenance materials and its construction technology, can solve the problems such as void blockage of drainage asphalt pavement, unsolved anti-scattering performance, loss of water seepage function, etc. , to achieve the effect of prolonging the life of the pavement, delaying the scattering of structural diseases, and improving the coefficient of friction of the pavement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

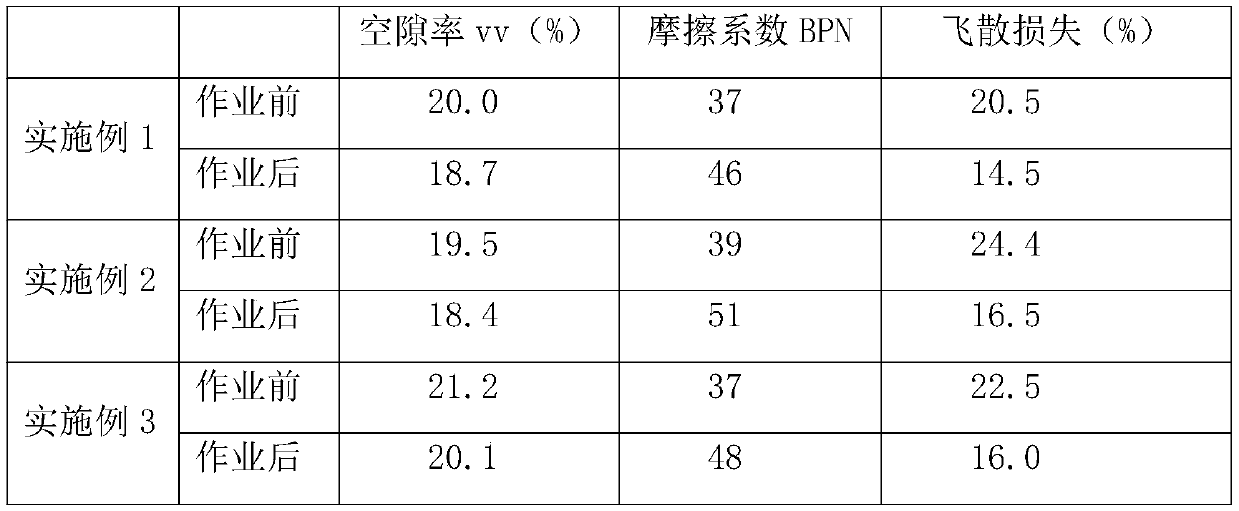

Embodiment 1

[0028] S01. Heating a certain amount of high-viscosity and high-elasticity modified asphalt with a dynamic viscosity of 220,000 Pa·s at 60°C to 170°C;

[0029] S02. According to viscosity reducer organic warm mix agent: modified asphalt is 3:100; diluent turpentine: modified asphalt is 20:100 by weight ratio, according to the above sequence, slowly add each component, and use mechanical stirring equipment to continuously Stir until uniform, and measure the temperature of the modified asphalt at 128°C after the stirring is completed, so that the diluted high-viscosity and high-elasticity modified asphalt is first obtained;

[0030] S03. Add the modified asphalt that has been stirred above into the automatic spraying vehicle, and turn on the vehicle insulation device, keep the temperature of the diluted modified asphalt at about 125°C, weigh hydrogen peroxide, and its concentration is 0.4%. According to the hydrogen peroxide solution: The diluted modified asphalt has a weight ra...

Embodiment 2

[0033] S01. Heating a certain amount of high-viscosity and high-elasticity modified asphalt with a dynamic viscosity of 250,000 Pa·s at 60°C to 175°C;

[0034] S02, according to viscosity reducer organic warm mixing agent: modified asphalt is 4:100; diluent turpentine: modified asphalt is 23:100 weight ratio, according to the above sequence, slowly add each component, and use mechanical stirring equipment to continuously Stir until uniform. After the stirring is completed, the temperature of the modified asphalt is measured to be 123°C, and the diluted high-viscosity and high-elasticity modified asphalt is obtained;

[0035] S03. Add the modified asphalt that has been stirred above into the automatic spraying vehicle, and turn on the vehicle insulation device, keep the temperature of the diluted modified asphalt at about 125°C, weigh hydrogen peroxide, and its concentration is 0.4%, according to the hydrogen peroxide solution : The diluted modified asphalt is in a weight ratio...

Embodiment 3

[0038] S01. Heating a certain amount of high-viscosity and high-elasticity modified asphalt with a dynamic viscosity of 270,000 Pa·s at 60°C to 180°C;

[0039] S02, according to viscosity reducer organic warm mixing agent: modified asphalt is 5:100; diluent turpentine: modified asphalt is 25:100 weight ratio, according to the above sequence, slowly add each component, and use mechanical stirring equipment to continuously Stir until uniform. After the stirring is completed, the temperature of the modified asphalt is measured to be 119°C, and the diluted high-viscosity and high-elasticity modified asphalt is obtained;

[0040] S03. Add the above-mentioned modified asphalt that has been stirred into the automatic spraying vehicle, and turn on the vehicle insulation device, keep the temperature of the diluted modified asphalt at about 125°C, weigh hydrogen peroxide, and its concentration is 0.5%. : The diluted modified asphalt is in a weight ratio of 12:100, slowly add hydrogen pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com