Energy-saving durable efficient reduction-distillation integrated electric furnace for titanium sponge production

A technology of sponge titanium and electric furnace, applied in the field of energy-saving, durable, high-efficiency reduction and distillation integrated electric furnace, can solve the problems of low production efficiency of sponge titanium, short service life of electric furnace, and high energy consumption of sponge titanium, so as to improve the rate of superior products and reduce unit energy. consumption and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

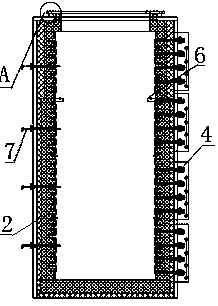

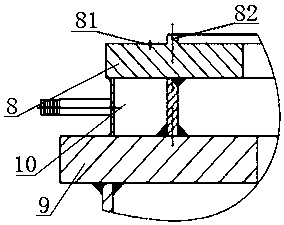

[0018] The energy-saving, durable, high-efficiency reduction and distillation integrated electric furnace for the production of sponge titanium according to the present invention includes a steel electric furnace shell, two sets of upper and lower flanges are arranged on the upper part of the furnace shell, and a forced circulation cooling water jacket is arranged between the upper and lower sets of flanges. A ring-shaped boss is set in the middle (or inside) of the upper flange, and a ring-shaped groove is set on the outside of the ring-shaped boss; the inner wall of the furnace shell is set with an insulation layer of aluminosilicate insulation cotton; Air inlet duct and one or more rows of annular air outlet channels, multiple air inlets are evenly arranged along the circumference from the annular air inlet duct in the insulation layer to the inside of the electric furnace, and multiple air outlets are evenly arranged along the circumference from the annular air outlet duct t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com