Novel pure oxygen smelting furnace and using method thereof

A smelting furnace and pure oxygen technology, applied in the field of boiler smelting, to achieve the effects of increasing reducibility, reducing pollutant emissions, accelerating indirect reduction efficiency and indirect reduction degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

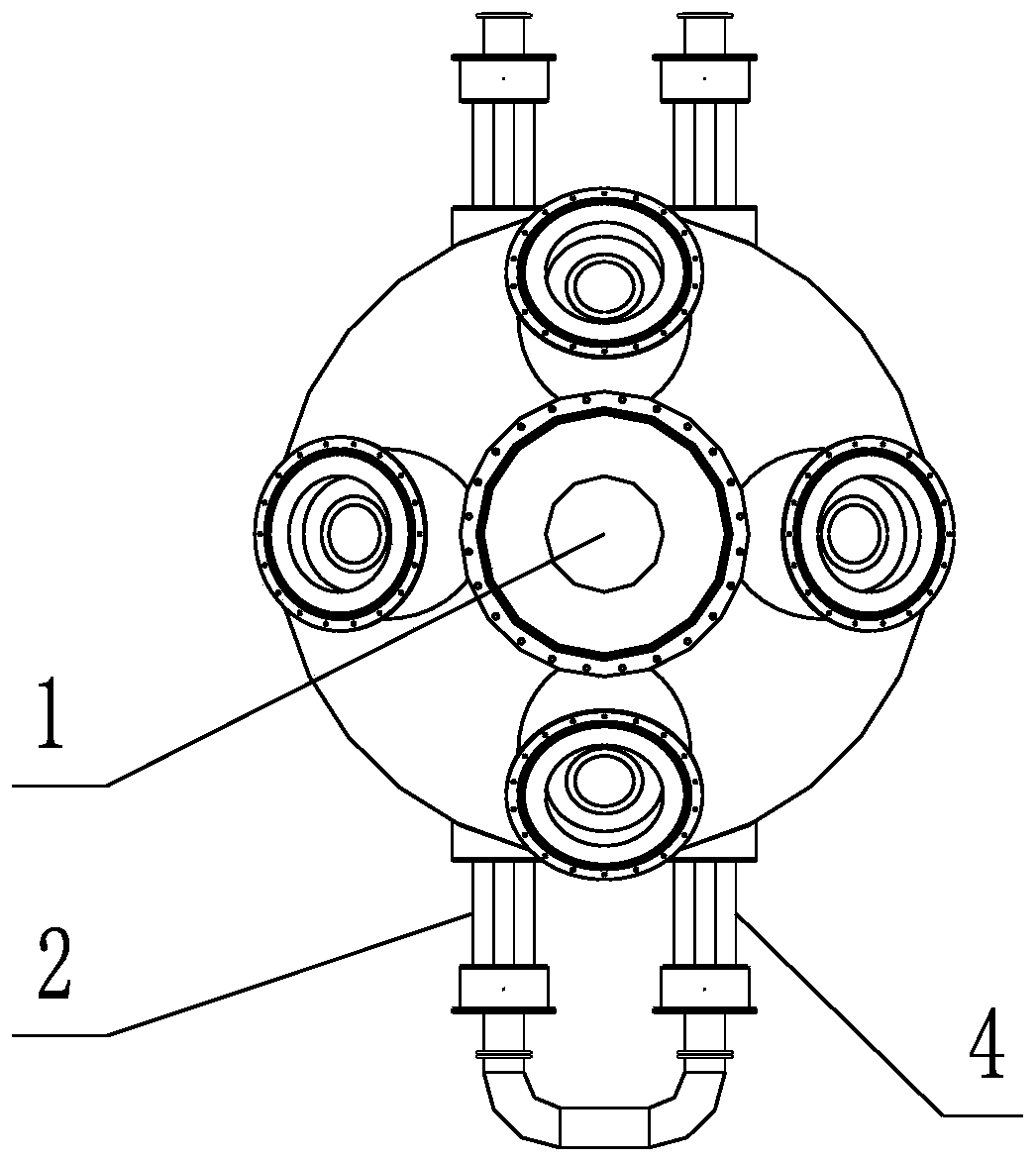

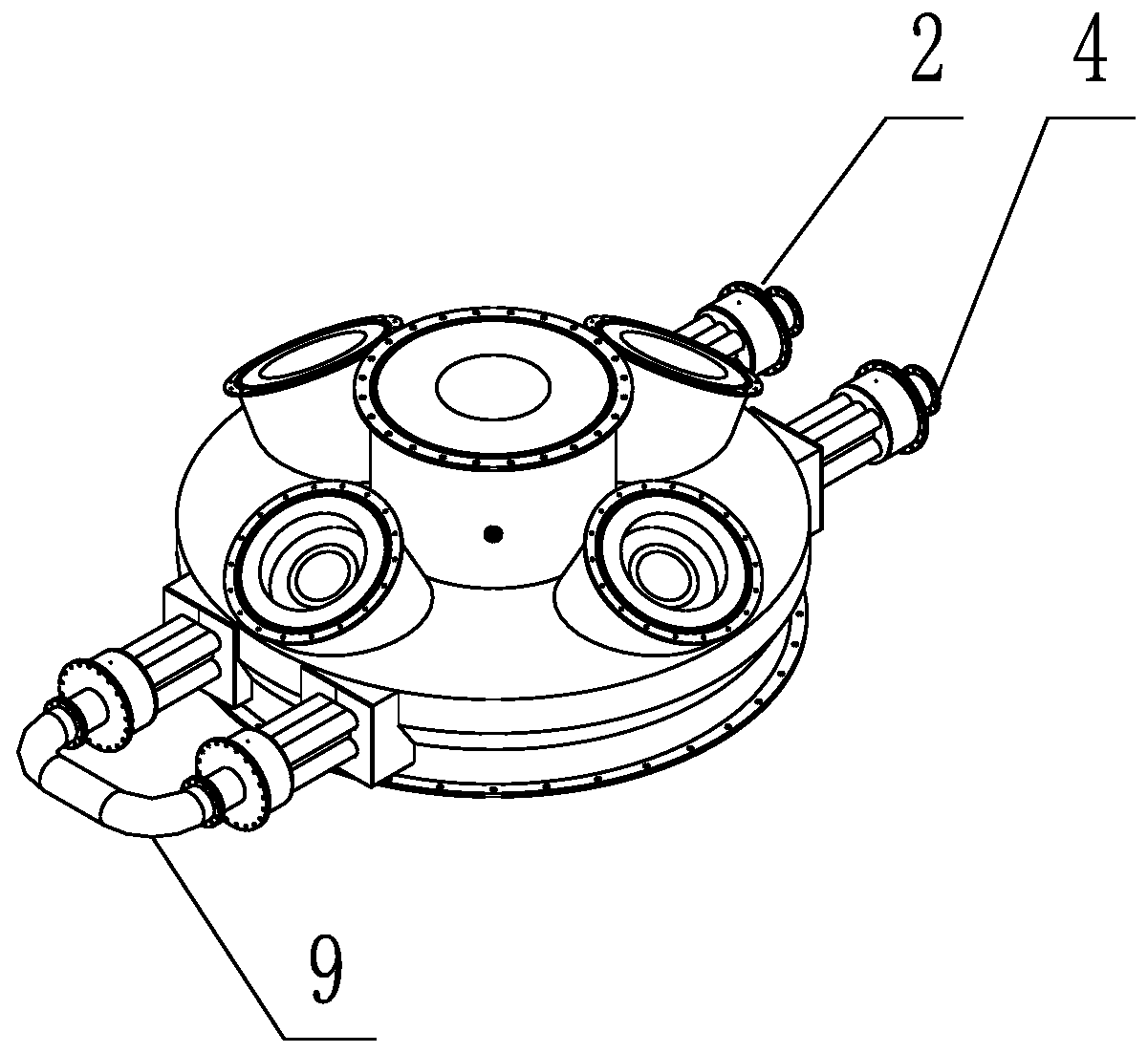

[0031] Attached below Figure 1-3 The novel pure oxygen smelting furnace of the present invention and its use method are described in detail.

[0032] A new type of pure oxygen smelting furnace. The new type of pure oxygen smelting furnace includes a furnace body and an automatic control system. The furnace body is fixedly arranged on the ground, and the furnace body has a hollow structure and is in the furnace body. A preheating section, a reduction reaction section, and a melting reaction section are arranged in order from top to bottom; the preheating section is provided with a feed inlet 1 for feeding at least one of raw material ore, coal, and coke, and There is a flue gas exhaust port 3; the melting reaction section is provided with a molten pool 10, the upper outer peripheral wall of the molten pool is fixedly provided with a combustion chamber 6 communicating with the molten pool, and the bottom center of the molten pool is also There is a sump 7; the sump is a bowl-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com