Silica gel composite material with high heat conductivity coefficient and excellent electromagnetic shielding performance

A composite material, electromagnetic shielding technology, applied in the direction of climate sustainability, sustainable manufacturing/processing, chemical industry, etc., can solve the problems of insufficient performance, high thermal conductivity cannot have electromagnetic shielding performance, etc., and achieve good electromagnetic shielding performance , The effect of good out-of-plane thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

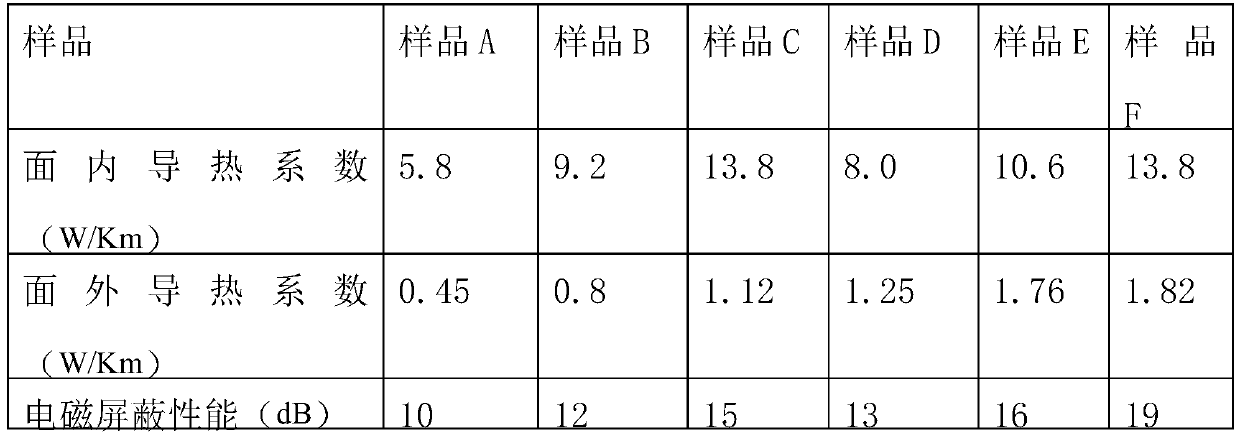

Examples

Embodiment 1

[0026] A silica gel composite material with high thermal conductivity and excellent electromagnetic shielding performance, the composition of the silica gel composite material is as follows:

[0027] MXene material 1-3g;

[0028] h-BN material 3-5g;

[0029] Single-layer graphene powder 0.5-1.5g;

[0030] Urea 20-50g;

[0031] Silica gel 10-45g;

[0032] Wherein the MXene material has the functions of electromagnetic shielding, heat conduction, and charge conduction; the h-BN material has the functions of insulation, coating, isolation of MXene, graphene nanosheets and heat conduction; the graphene has the functions of electromagnetic shielding , the function of heat conduction; the urea is an intercalation stripping reagent, which also has the function of modifying the surface of the two-dimensional material;

[0033] The MXene material, h-BN material, and graphene are used as fillers. After the fillers are stripped by urea molecules under the condition of plasma ball mil...

Embodiment 2

[0037] A silica gel composite material with high thermal conductivity and excellent electromagnetic shielding performance, the filler concentration is controlled at a ratio of 20wt%, and the specific components of the silica gel composite material are as follows: MXene material 1g; h-BN material 3g; graphene 1g; urea 25g ; Silica gel 20g.

[0038] The MXene material, the h-BN material, and the graphene were stripped with urea and mixed by ball milling to prepare fillers, which were then dispersed in silica gel, and samples were taken for testing B.

Embodiment 3

[0040] A silica gel composite material with high thermal conductivity and excellent electromagnetic shielding performance, the filler concentration is controlled at a ratio of 30wt%, and the specific components of the silica gel composite material are as follows: MXene material 1g; h-BN material 3g; graphene 1g; urea 25g ;Silicone 12g.

[0041] The MXene material, the h-BN material, and the graphene were all stripped with urea and mixed by ball milling to prepare fillers, which were then dispersed in silica gel, and samples were taken for testing C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com