Preparation method of high-luminous-efficiency fluorapatite complex-phase fluorescent ceramic material for LED/LD illumination

A technology using fluorapatite and fluorescent ceramics, applied in the directions of luminescent materials, chemical instruments and methods, can solve the problems that have not yet been developed, and can ensure the optical quality and luminescent performance of ceramics, short preparation period and good uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

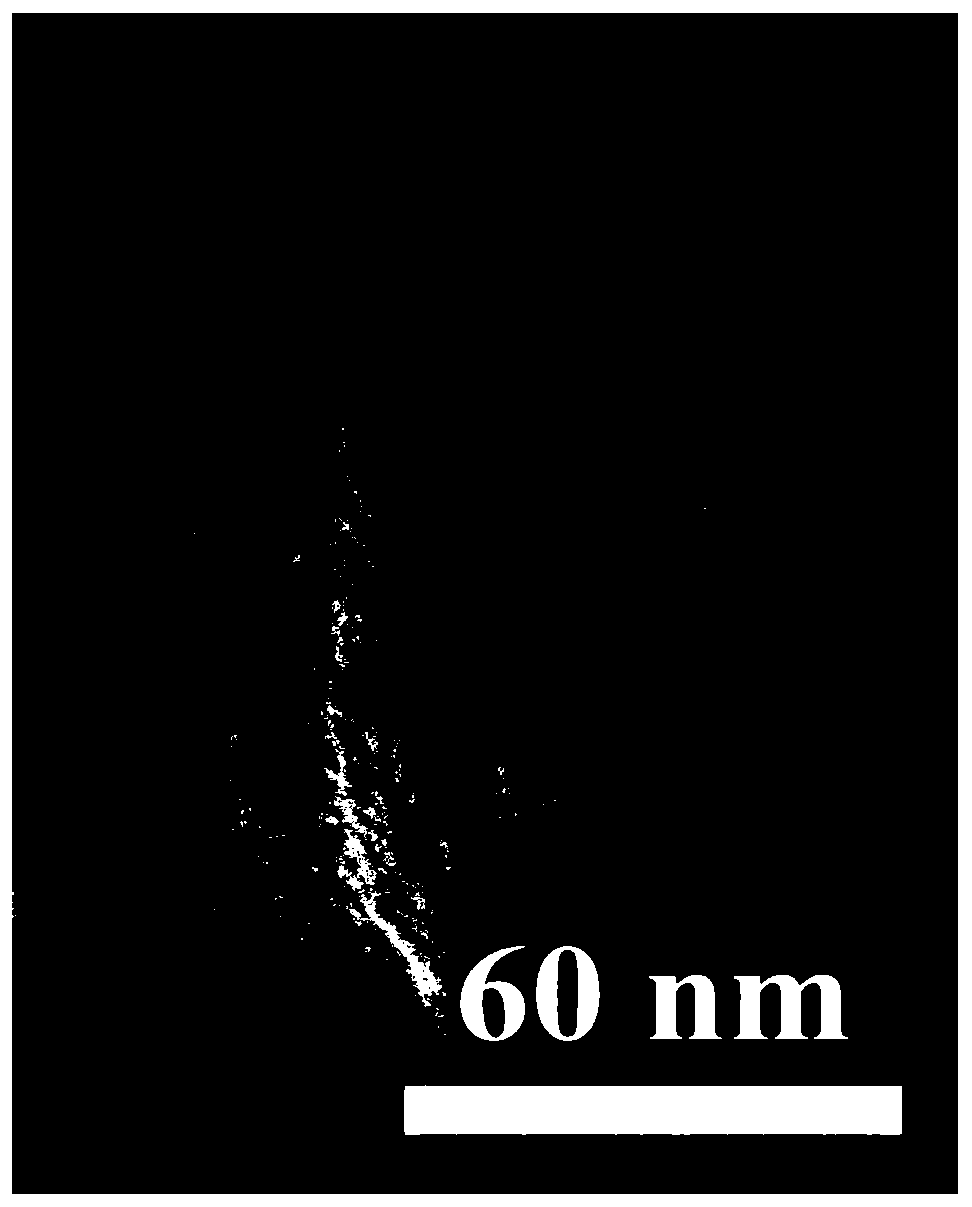

Image

Examples

Embodiment 1

[0038] A preparation method of fluoroapatite composite fluorescent ceramic material for LED / LD lighting with high light efficiency, the specific steps are as follows:

[0039] (1) According to molecular formula (Ce 0.001 Y 0.999 ) 3 al 5 o 12 The stoichiometric ratios of the corresponding elements were accurately weighed for Y with a purity of 99.999%. 2 o 3 Powder, 99.999% Al 2 o 3 Powder and 99.99% CeO 2 Powder, all three powder materials are dissolved in analytically pure nitric acid with a concentration of 14mol / L to form a powder containing Y 3+ 、Al 3+ 、Ce 3+ mother solution of ions, Y 3+ 、Al 3+ 、Ce 3+ The total molar weight of the three ions is the standard, and the mother liquor is diluted to 0.12mol / L; the analytically pure ammonium sulfate is added to the mother liquor as a dispersant, and its addition amount is Y 3+ 4mol% of the molar weight;

[0040] (2) Preparation of precipitant mixed solution: according to the molar ratio of 1:3, analytically pure ...

Embodiment 2

[0052] A preparation method of fluoroapatite composite fluorescent ceramic material for LED / LD lighting with high light efficiency, the specific steps are as follows:

[0053] (1) According to molecular formula (Ce 0.0005 Y 0.9995 ) 3 al 5 o 12 The stoichiometric ratios of the corresponding elements were accurately weighed for Y with a purity of 99.999%. 2 o 3 Powder, 99.999% Al 2 o 3 Powder and 99.99% CeO 2 Powder, all three powder materials are dissolved in analytically pure nitric acid with a concentration of 12mol / L to form a powder containing Y 3+ 、Al 3+ 、Ce 3+ mother solution of ions, Y 3+ 、Al 3+ 、Ce 3+ The total molar weight of the three ions is taken as the standard, and the mother liquor is diluted to 0.18mol / L; the analytically pure ammonium sulfate is added to the mother liquor as a dispersant, and its addition amount is Y 3+ 3mol% of the molar weight;

[0054] (2) Preparation of precipitant mixed solution: According to the molar ratio of 1:2.5, analy...

Embodiment 3

[0063] (1) According to molecular formula (Ce 0.006 Y 0.994 ) 3 al 5 o 12 The stoichiometric ratios of the corresponding elements were accurately weighed Y with a purity of 99.99%. 2 o 3 Powder, 99.999% Al 2 o 3 Powder and 99.999% CeO 2 Powder, all three powder materials are dissolved in analytically pure nitric acid with a concentration of 10mol / L to form a powder containing Y 3+ 、Al 3+ 、Ce 3+ mother solution of ions, Y 3+ 、Al 3+ 、Ce 3+ The total molar weight of the three ions is taken as the standard, and the mother liquor is diluted to 0.06mol / L; the analytically pure ammonium sulfate is added to the mother liquor as a dispersant, and its addition amount is Y 3+ 2mol% of molar weight;

[0064] (2) Preparation of precipitant mixed solution: According to the molar ratio of 1:4, analytically pure ammonia water and ammonium bicarbonate are evenly prepared by magnetic stirring, wherein the mass fraction of ammonia water is 25-28%, and the concentration of ammonium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap