Heavy metal sewage treatment system

A sewage treatment system and heavy metal technology, applied in water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of biochemical system collapse, increase biological toxicity, increase operation difficulty, etc., to achieve High matching degree, stable chemical properties, simple and clear process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

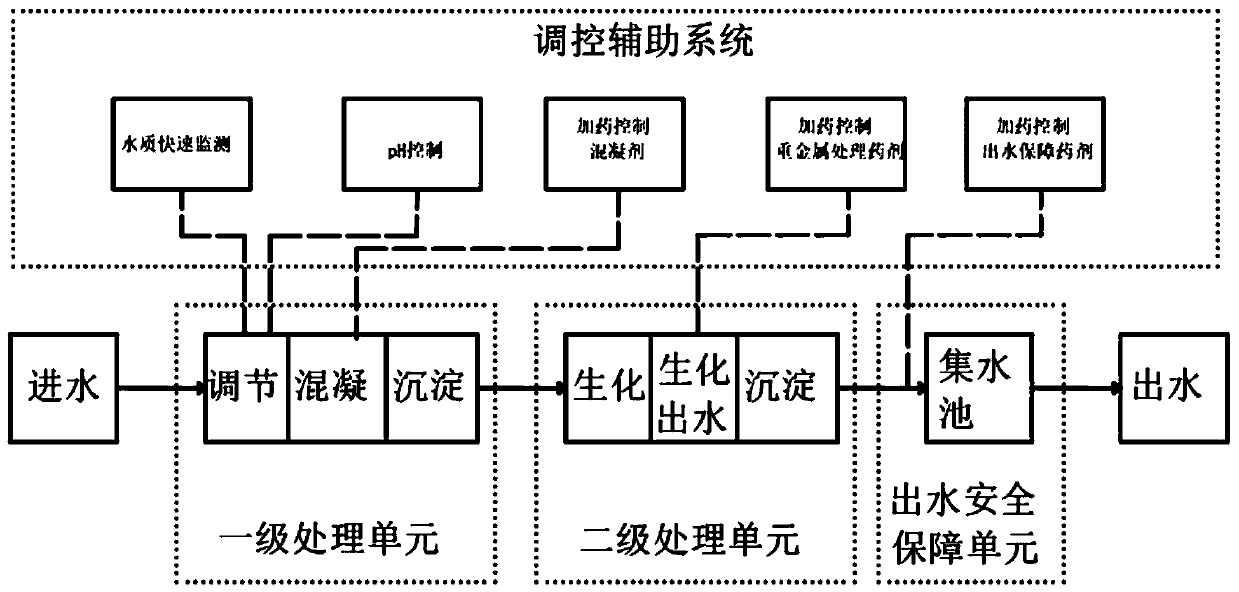

[0069] The main process of the treatment facilities of a sewage treatment plant adopts the AAO activated sludge method. The suspended solids in the wastewater entering the plant contain heavy metals such as copper ions, nickel ions and manganese ions. The treatment process does not design a heavy metal removal unit, resulting in heavy metals in the effluent exceeding the discharge standard . This embodiment adopts figure 1 The system shown, treats the above-mentioned sewage, as follows:

[0070] (1) Sewage enters the regulating tank of the primary treatment unit, detects the pH through the pH value detection sensor in the rapid monitoring module of the influent water quality of the auxiliary system for regulation, and feeds back to the pH control module of the auxiliary system for regulation, and controls the primary reaction unit The acid / alkali dosing pump in the adjustment tank is automatically turned on and off to adjust the pH value of the sewage to pH6.8, and the adjust...

Embodiment 2

[0079] The main process of the treatment facilities of a sewage treatment plant adopts the AAO activated sludge method. The suspended solids in the wastewater entering the plant contain heavy metals such as lead ions, nickel ions, and zinc ions. The treatment process does not design a heavy metal removal unit, resulting in heavy metals in the effluent exceeding the discharge standard . This embodiment adopts figure 1 The system shown, treats the above-mentioned sewage, as follows:

[0080] (1) Sewage enters the regulating pool of the primary treatment unit, and the pH is detected by the pH value detection sensor in the rapid monitoring module of the influent water quality of the auxiliary system for regulation and control, and fed back to the pH control module of the auxiliary system for regulation and control, through the control of the primary treatment unit The acid / alkali dosing pump in the adjustment tank is automatically opened and closed to adjust the pH value of the s...

Embodiment 3

[0089] The main process of the treatment facility of a sewage treatment plant adopts the AAO activated sludge method. The suspended solids in the wastewater entering the plant contain heavy metals such as mercury ions, chromium ions, and manganese ions. The treatment process does not design a heavy metal removal unit, resulting in heavy metals in the effluent exceeding the discharge standard . This embodiment adopts figure 1 The system shown, treats the above-mentioned sewage, as follows:

[0090] (1) Sewage enters the regulating tank of the primary treatment unit, detects the pH through the pH value detection sensor in the rapid monitoring module of the influent water quality of the auxiliary system for regulation, and feeds back to the pH control module of the auxiliary system for regulation, and controls the primary reaction unit The acid / alkali dosing pump in the adjustment tank is automatically turned on and off to adjust the pH value of the sewage to pH6.8, and the adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com