Environment-friendly boiler deoxidant

A kind of deoxidizer and environment-friendly technology, applied in the field of deoxidizer for environment-friendly boilers, it can solve the problems of large amount of deoxidizer and general cleaning speed, and achieves a good cleaning effect, fast cleaning speed and high oxygen absorption reaction speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

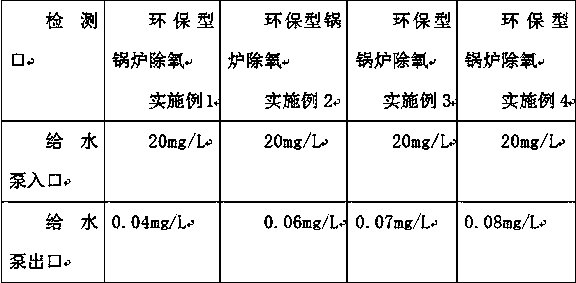

Examples

Embodiment 1

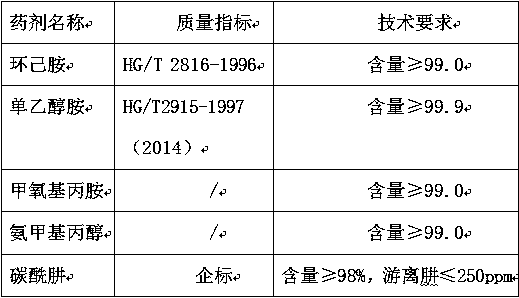

[0017] The environmentally friendly boiler deoxidizer in this embodiment is made of the following raw materials by weight: 2 parts carbohydrazide, 45 parts neutralizing amine and 53 parts deionized water, wherein the neutralizing amine is made by mass ratio

[0018] 1:1.5:1.5:0.5 cyclohexylamine, monoethanolamine, methoxypropylamine and aminomethylpropanol are mixed; specifically, it is made by the following steps:

[0019] Step 1: Preparation of neutralized amine: first put cyclohexylamine into the preparation kettle, turn on the stirring, and then put in monoethanolamine, methoxypropylamine and aminomethylpropanol in sequence to make cyclohexylamine, monoethanolamine, and methoxy Propylamine and aminomethylpropanol meet the quality requirements of 1:1.5:1.5:0.5, and stir for 1-2 hours to ensure that the materials are evenly mixed and formulated into neutralized amine;

[0020] Step 2: Add deionized water to the reactor, then add carbohydrazide, turn on the stirring, after the carbo...

Embodiment 2

[0022] The environmentally friendly boiler deoxidizer in this embodiment is made of the following raw materials by weight: 8 parts carbohydrazide, 45 parts neutralizing amine and 47 parts deionized water, wherein the neutralizing amine is made by mass ratio

[0023] 1:1.5:1.5:0.5 cyclohexylamine, monoethanolamine, methoxypropylamine and aminomethylpropanol are mixed; specifically, it is made by the following steps:

[0024] Step 1: Preparation of neutralized amine: first put cyclohexylamine into the preparation kettle, turn on the stirring, and then put in monoethanolamine, methoxypropylamine and aminomethylpropanol in sequence to make cyclohexylamine, monoethanolamine, and methoxy Propylamine and aminomethylpropanol meet the quality requirements of 1:1.5:1.5:0.5, and stir for 1-2 hours to ensure that the materials are evenly mixed and formulated into neutralized amine;

[0025] Step 2: Add deionized water to the reactor, then add carbohydrazide, turn on the stirring, after the carbo...

Embodiment 3

[0027] The environmentally friendly boiler deoxidizer in this embodiment is made of the following raw materials by weight: 2 parts carbohydrazide, 45 parts neutralizing amine and 53 parts deionized water, wherein the neutralizing amine is made by mass ratio

[0028] 1.5:1.0:1.5:0.5 cyclohexylamine, monoethanolamine, methoxypropylamine and aminomethylpropanol are mixed; specifically, it is made by the following steps:

[0029] Step 1: Preparation of neutralized amine: first put cyclohexylamine into the preparation kettle, turn on the stirring, and then put in monoethanolamine, methoxypropylamine and aminomethylpropanol in sequence to make cyclohexylamine, monoethanolamine, and methoxy Propylamine and aminomethylpropanol meet the quality requirements of 1.5:1.0:1.5:0.5, and stir for 1-2 hours to ensure that the materials are evenly mixed and formulated into a neutralized amine;

[0030] Step 2: Add deionized water to the reactor, then add carbohydrazide, turn on the stirring, after the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com