Breathable packing material for medicine bags of fresh keeping agent

A technology of bags and medicines, applied in bags, packaging, sacks, etc., can solve the problems of powder leakage, unstable air permeability, and oxygen absorption speed that cannot meet the needs of keeping meat and fish fresh, and achieve the purpose of absorbing residual particles The effect of strong oxygen capacity and high oxygen absorption reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

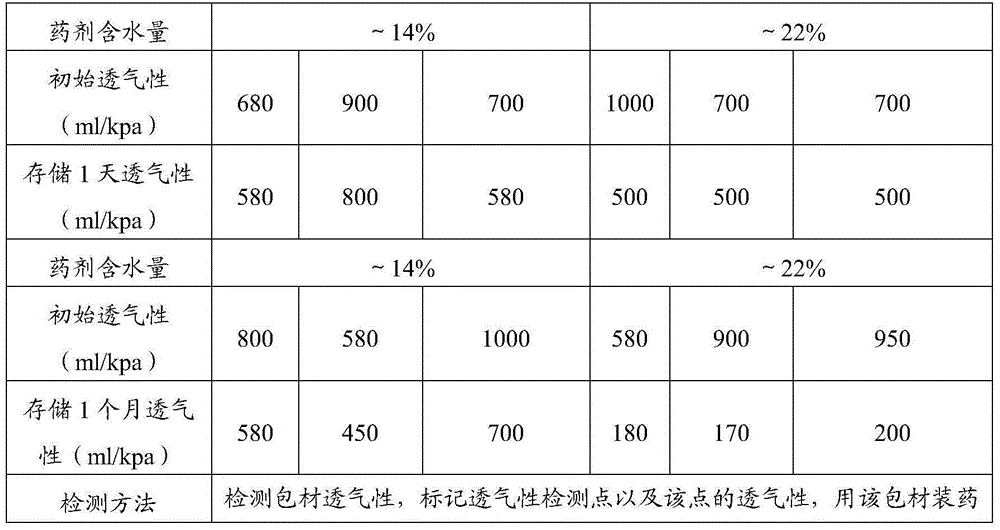

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Iron powder treatment includes iron powder and a water film layer attached to the surface of the iron powder. In this embodiment, the iron powder is reduced iron powder with a particle size of 200-300 mesh, and the water The film layer includes powdered calcium chloride with a quality of 2.1% of the total mass of the iron powder to be treated, powdered activated carbon with a quality of 2.6% of the total mass of the iron powder to be treated, and water with a quality of 1.0% of the total mass of the iron powder to be treated. The thickness of the layer is 0.4 μm.

Embodiment 2

[0023] Embodiment 2: Iron powder treatment includes iron powder and a water film layer attached to the surface of the iron powder. In this embodiment, the iron powder is reduced iron powder with a particle size of 100-300 mesh, and the water The film layer includes powdery sodium chloride and calcium chloride whose quality is 0.9% of the total mass of the iron powder to be treated, powdered activated carbon whose quality is 3.9% of the total mass of the iron powder to be treated, and 0.6% of the total mass of the iron powder to be treated. Water, the thickness of the water film layer is 1.2 μm.

Embodiment 3

[0024] Embodiment 3: Iron powder treatment includes iron powder and a water film layer attached to the surface of the iron powder. In this embodiment, the iron powder is high-carbon iron powder with a particle size of 80-300 mesh, and the Water film layer comprises that quality is to handle the powdered calcium chloride of iron powder gross mass 3% and thiosulfate (big soda), the quality is to handle the powdery activated carbon of 2.2% of iron powder gross mass and the quality is to handle iron powder 1.5% of the total mass of water, the thickness of the water film layer is 0.4mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com