Grinding method for high-forming-precision seal head

A high-formation and head-sealing technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve the problems of low forming precision requirements, to ensure the protection effect, avoid falling off, easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

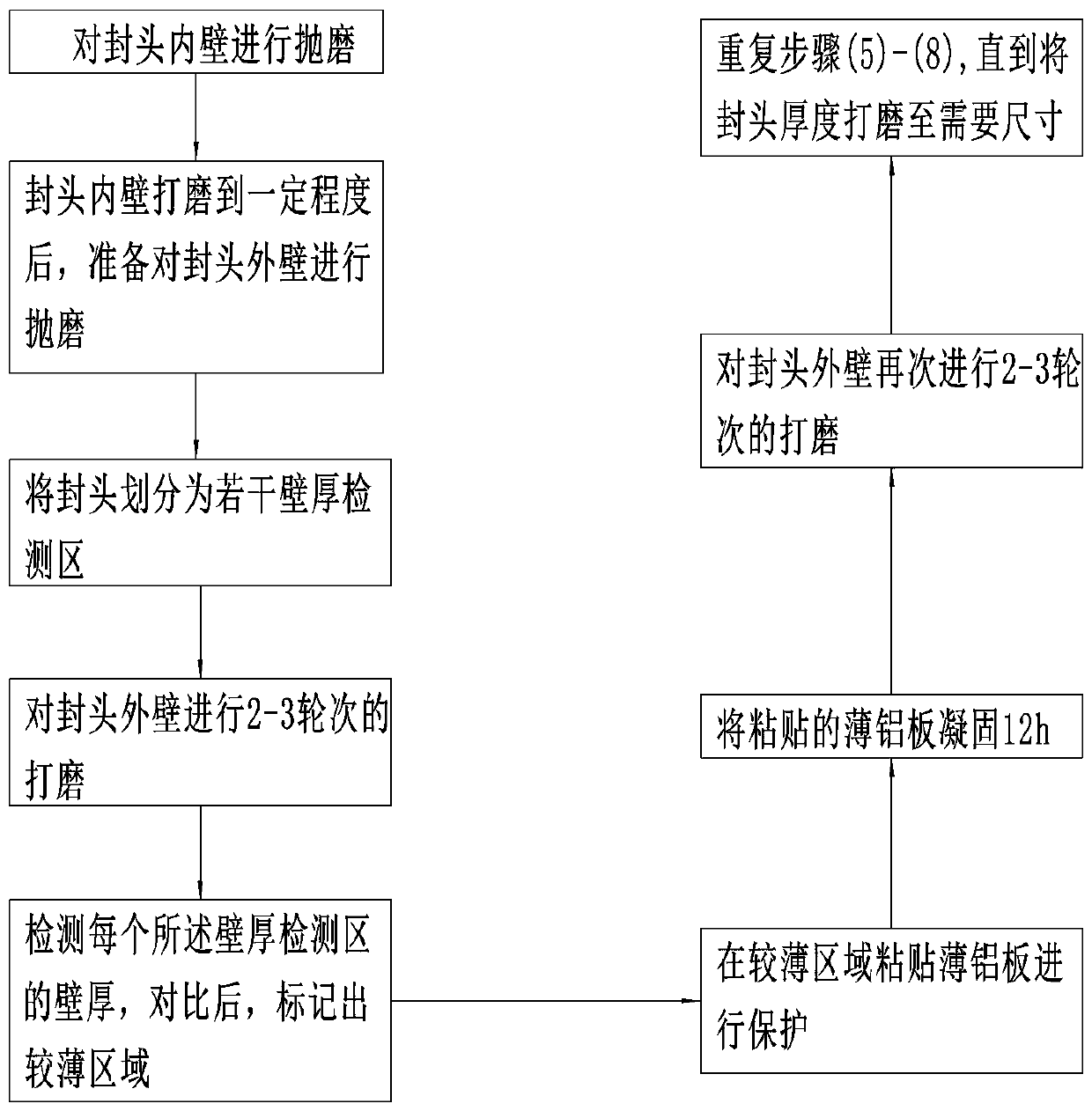

[0019] Such as figure 1 As shown, a high forming precision head grinding method includes the following steps:

[0020] (1) First set the open end of the head upwards on the working turntable of the polishing machine, and polish the inner wall of the head;

[0021] (2) After the inner wall of the head is polished to a certain extent, set the open end of the head down on the working turntable of the polishing machine;

[0022] (3) Divide the entire head from the open end to the closed end into several circumferential sections, and evenly divide the area on the same circumferential section into several wall thickness detection areas;

[0023] (4) Start the polishing machine, and the polishing belt on the polishing machine fits the outer surface of the head for 2-3 rounds of grinding. During the grinding process, continuously spray cooling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com