Elastic supporting structure type bearing outer ring finish lapping machining method

A technology of bearing outer ring and structure type, which is applied in the field of fine grinding and processing of elastic structure type bearing outer ring, which can solve the problems of low product precision, achieve the effect of improving stability and meeting processing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

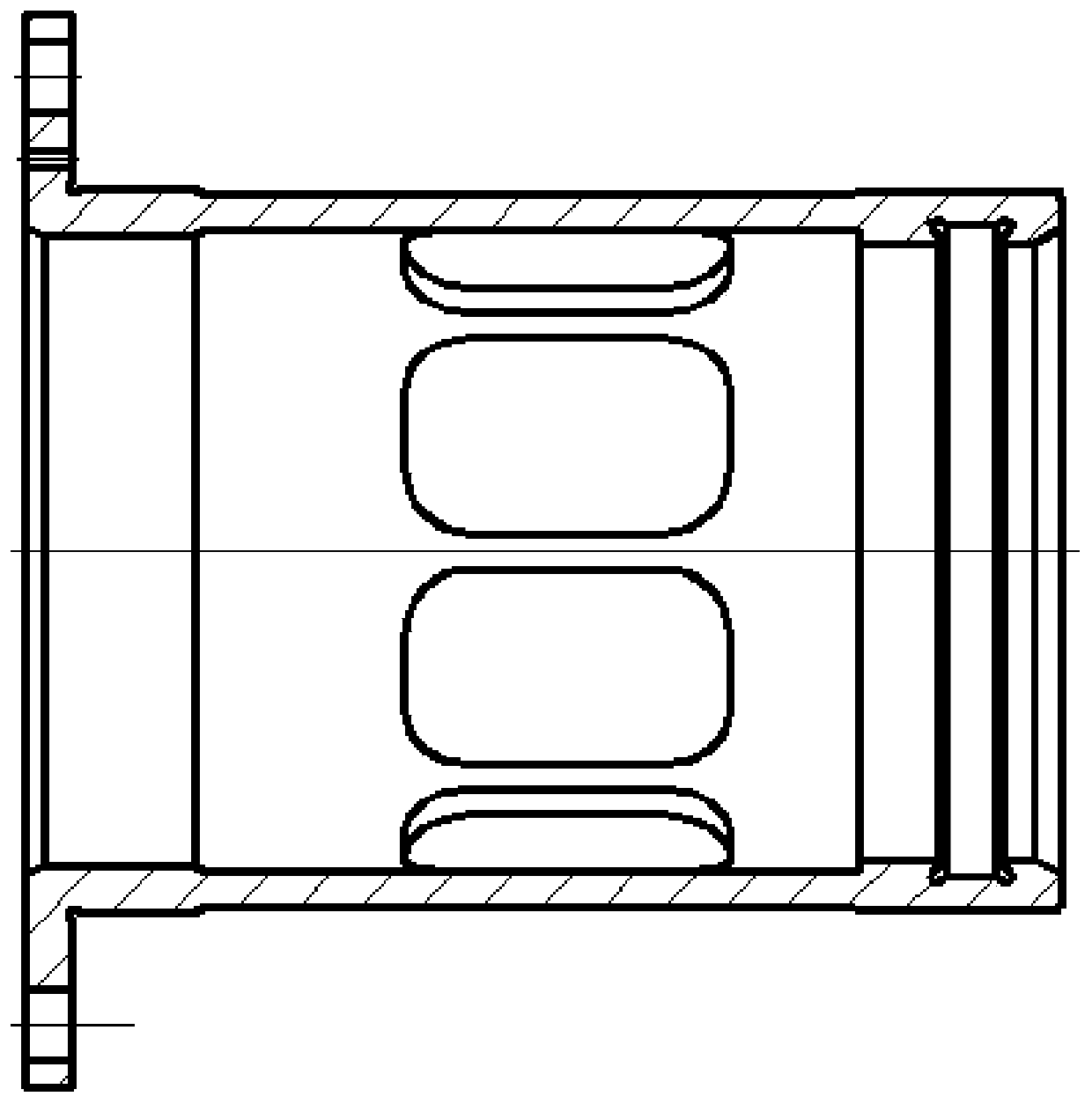

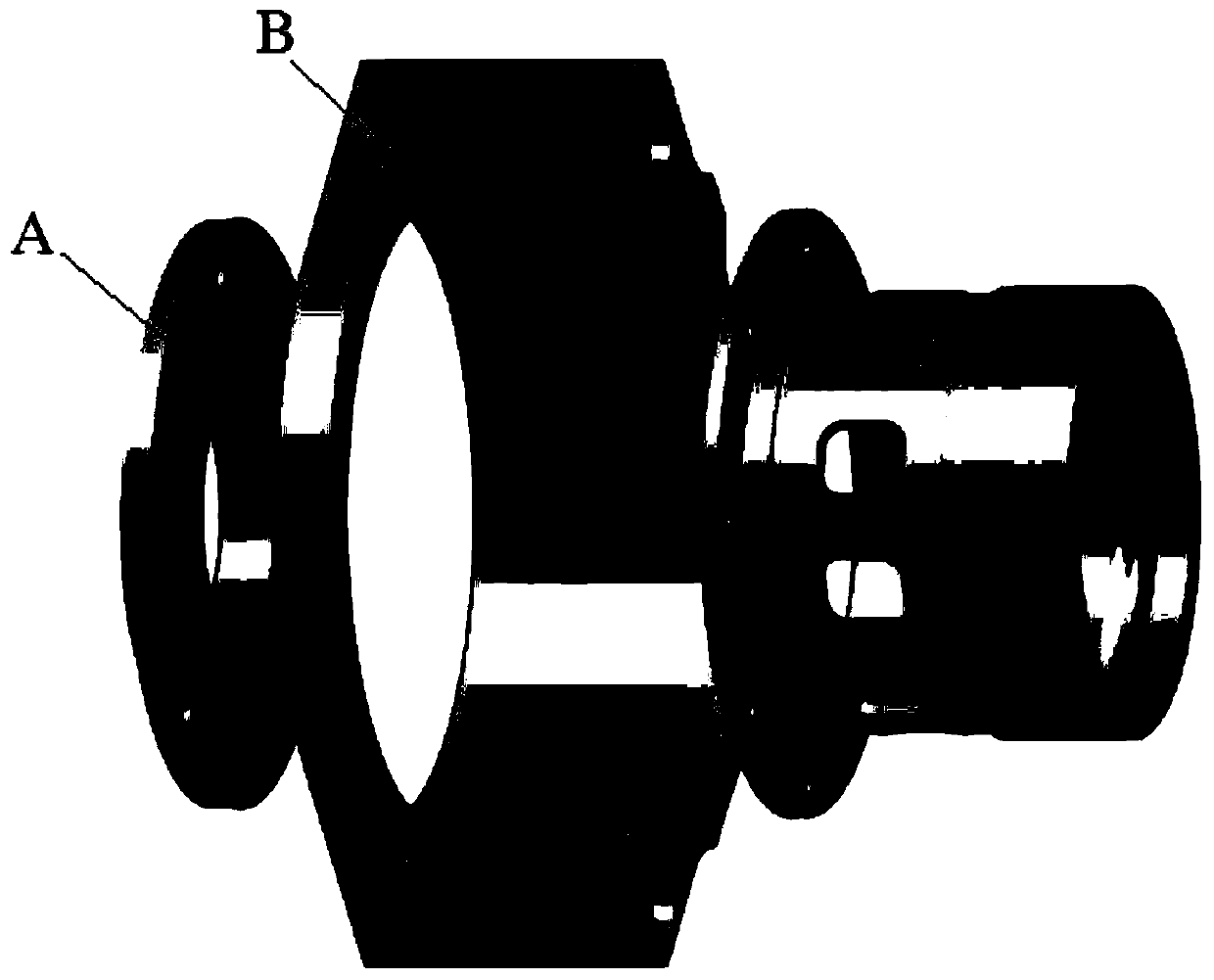

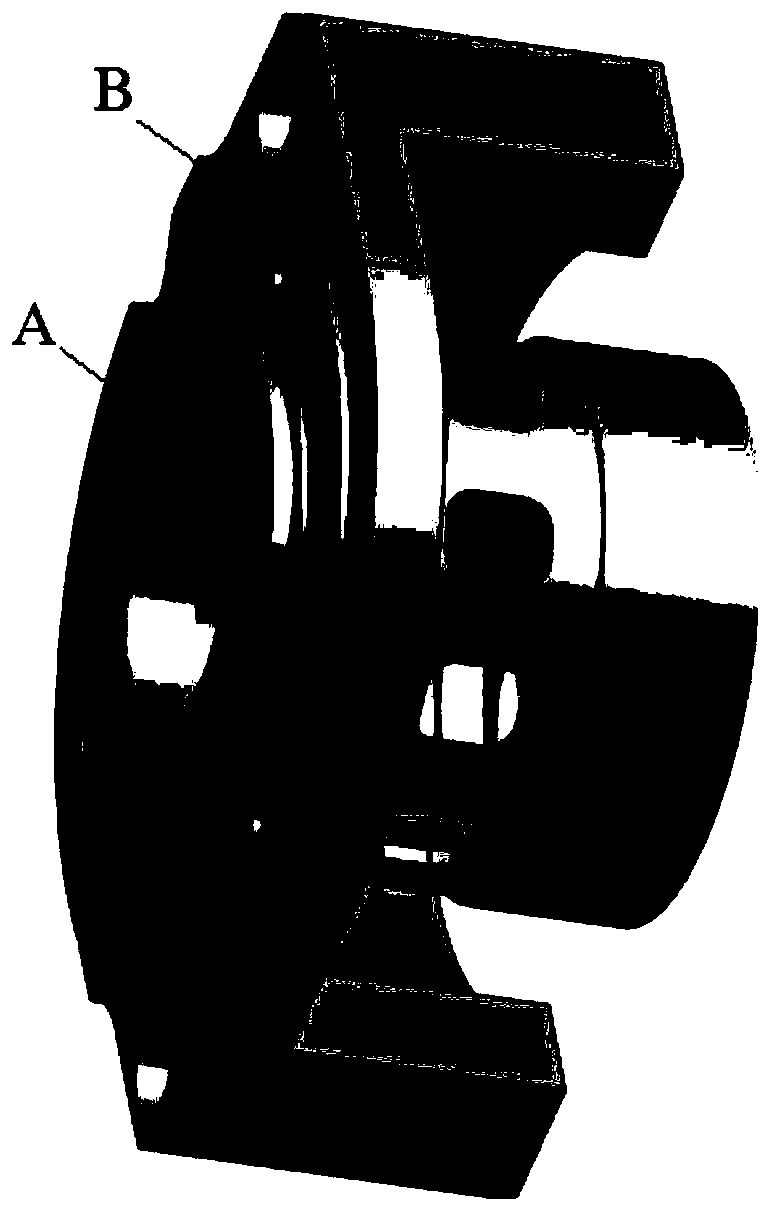

[0022] Specific implementation mode one: combine Figure 1 to Figure 7 , this embodiment is a fine grinding method for the outer ring of a spring-supported structure type bearing, which is specifically completed according to the following steps:

[0023] 1. Design special tooling: ①. Mat of lapping machine: Pad A of lapping machine is composed of machine tool installation part 1 and bearing contact part 2. Machine tool installation part 1 is designed according to BS122 lapping machine installation requirements, and bearing contact part 2 is Plane type, the radial cross-sectional size of the bearing contact part 2 is designed in conjunction with the elastic support structure type bearing size, the thickness of the tire pad A of the lapping machine is 10mm, and the thickness of the bearing contact part 2 is 5mm; ②, special C-type fulcrum : The radial section size of the special C-type fulcrum is designed according to the installation requirements of BS122 finishing machine, and ...

specific Embodiment approach 2

[0030] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the process of rough grinding the bearing outer ring described in step 4 is as follows: use Dalman CB9 oil stone as the finishing oil stone to rough grind the bearing outer ring, and rough grind the bearing The operating parameters of the outer ring: the rough grinding time is 15s, the spindle speed is 233rpm, the oilstone oscillation frequency is 1088Hz, and the oilstone pressure is 1.5MPa. Others are the same as the first embodiment.

specific Embodiment approach 3

[0031] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the process of finely grinding the outer ring of the bearing described in step 4 is as follows: use Dalman CB9 oil stone as the fine grinding oil stone to finely grind the outer ring of the bearing, The operating parameters of the fine grinding bearing outer ring: the fine grinding processing time is 15s, the spindle speed is 433rpm, the oilstone oscillation frequency is 988Hz, and the oilstone pressure is 1.5MPa. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com