Automatic egg breaking machine

A technology of egg and special machine, which is applied in the field of automatic egg breaking machine, can solve the problem of broken shells falling into eggs, and achieve the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

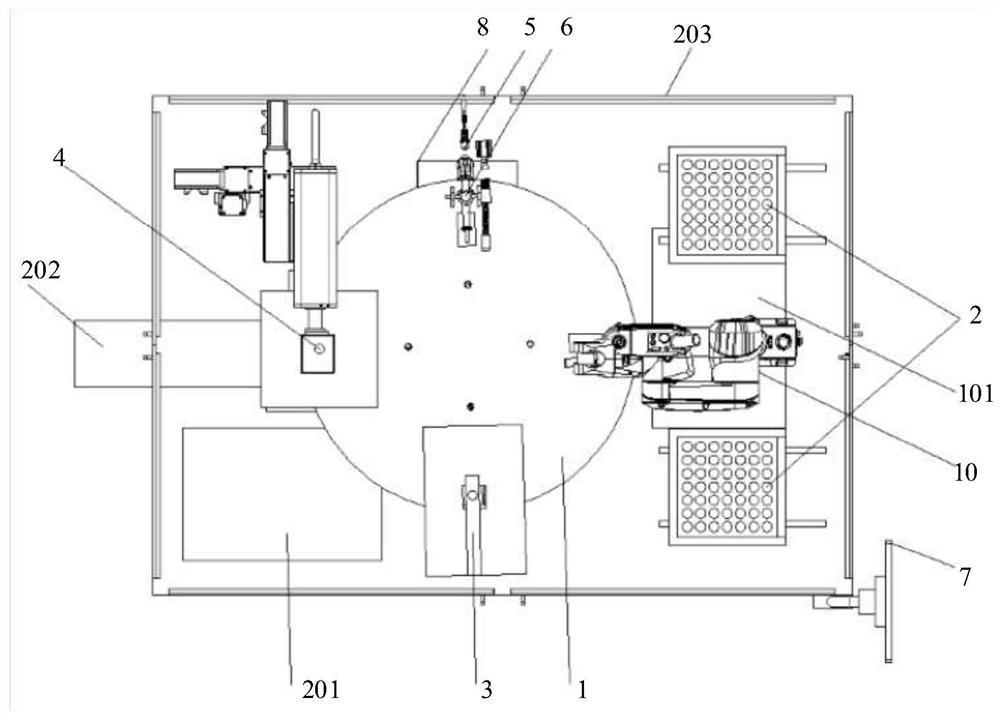

[0081] Figure 8 It shows a ring-shaped egg loading and unloading station diagram in the embodiment of the present invention, and its working process is as follows:

[0082] A. The loading and unloading station includes a loading and unloading multi-axis robot (which can be replaced manually), a robot electrical control box, a loading and unloading tray, and a station egg tray mechanism.

[0083] B. The loading and unloading station adopts multi-axis robots to realize loading and unloading through customized fixtures or manual replacement.

[0084] C. The loading and unloading stations use trays to feed materials, and the completed trays and new loading trays do not affect each other.

[0085] D. There is a slide rail mechanism at the bottom of the pallet of the loading and unloading station to support the pallet to slide out of the special machine shell for pallet replacement.

[0086] E. Eggs at the loading and unloading station are placed on the egg tray mechanism with th...

Embodiment 4

[0130] Introduction to the technological process of the circular layout special plane:

[0131] Step 1: Manually position the egg tray to be processed on the loading and unloading station.

[0132] Step 2: The loading and unloading robot is equipped with a jig, and the eggs are sequentially grabbed by the jig (or manually) and fed to the station egg tray mechanism.

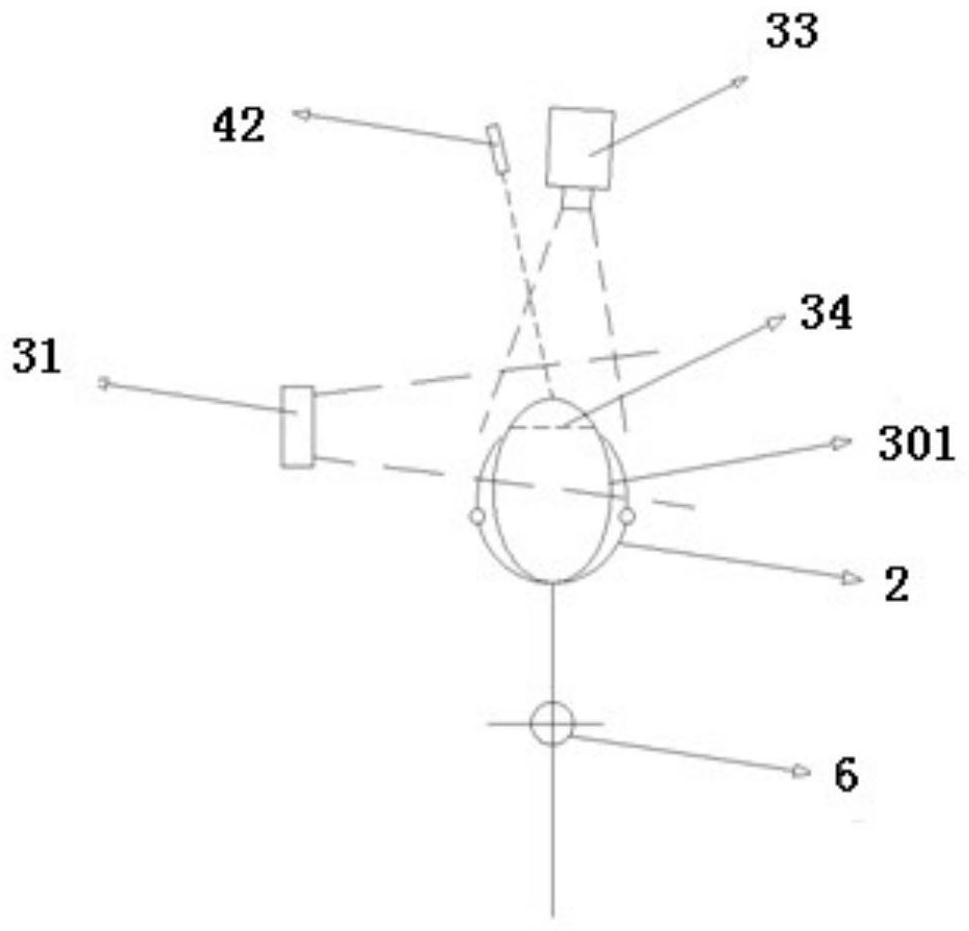

[0133] Step 3: The central turntable rotates, and the station egg tray mechanism moves to the visual inspection station through the turntable.

[0134] Step 4: The vision system finds the position and size of the cavity through the cooperation of vision and light source, and uses infrared distance measurement to detect the opening position of the egg.

[0135] Step 5: The station egg tray moves with the turntable to the laser shell burning station. The robot holds the laser head and flexibly burns out the opening marks according to the feedback of the visual system.

[0136] Step 6: The station egg tray moves wi...

Embodiment 5

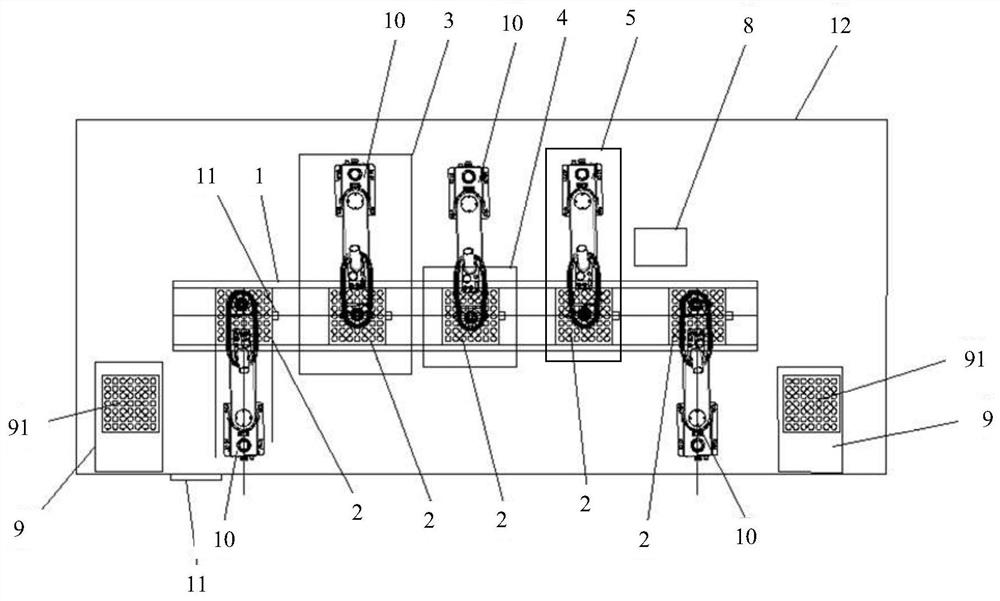

[0140] Introduction to the process flow of the linear layout special machine:

[0141] Step 1: Manually position and place the egg tray to be processed on the loading station (or on the feeding conveyor line).

[0142] Step 2: The feeding robot (or manual) holds the fixture, and sequentially grabs the egg tray through the fixture (or manual) and loads it to the station with positioning function of the double-speed chain or synchronous belt.

[0143] Step 3: The tray mechanism of the egg tray moves to the visual inspection station through the transmission of the double-speed chain or the synchronous belt.

[0144] Step 4: The multi-axis robot holds the vision system to find out the position and size of the cavity of each egg through the cooperation of vision and light source, and uses infrared ranging to detect the height of the opening position of each egg; and then transmits the data to the laser burner Erosion station use. After the visual inspection of the whole tray of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com