A positioning drilling rotary table

A technology of a rotary table and a positioning device, which is used in positioning devices, precision positioning equipment, and drilling dies for workpieces, etc., can solve the problems of drilling position accuracy deviation, time-consuming and labor-consuming, and installation difficulties, and avoid drilling holes. Variation in positional accuracy, convenient drilling process, and effect of shortening machining time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

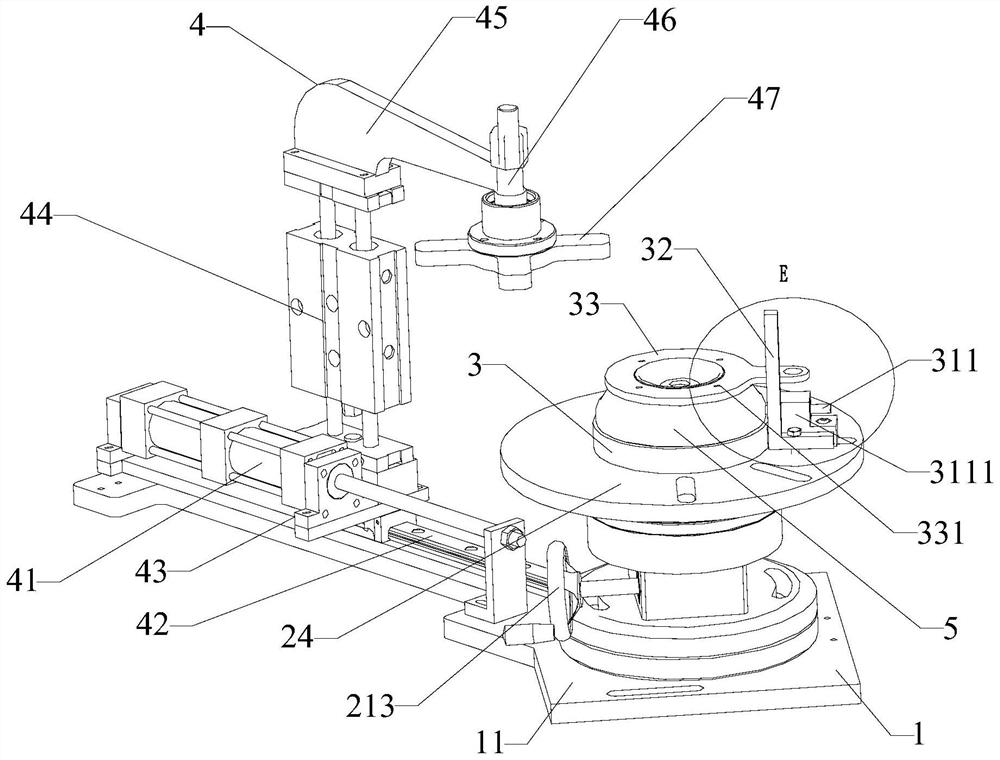

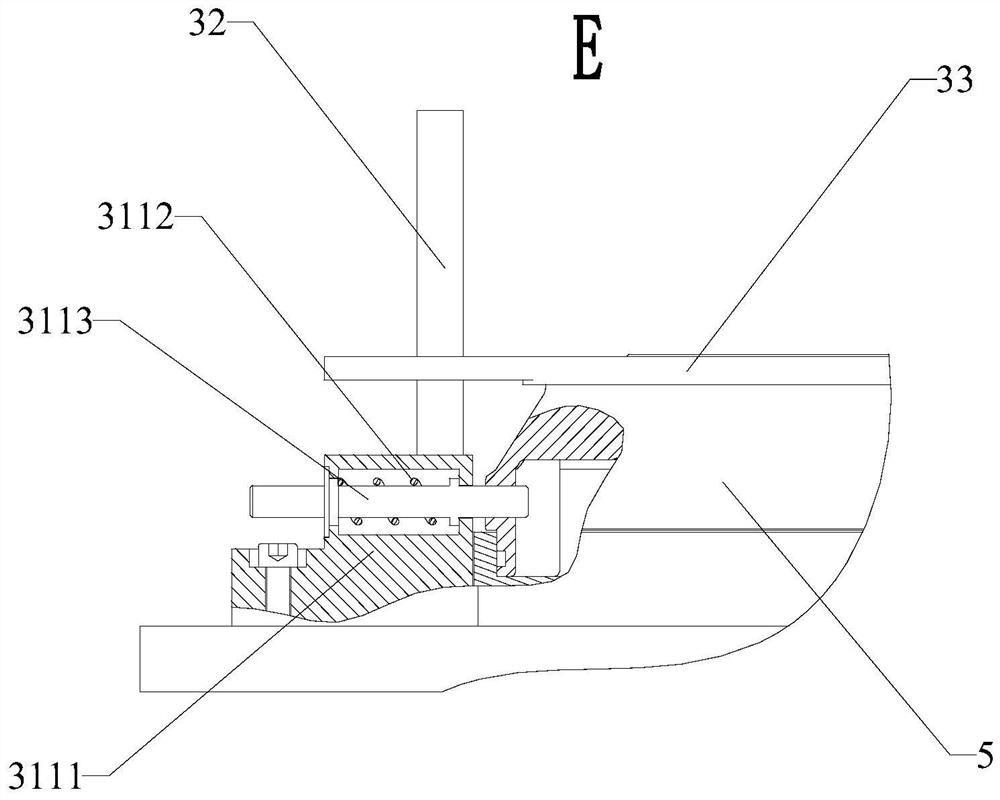

[0043]A positioning drilling rotary table, including a base 1, a turntable 2 and an end cap positioning device 3; the turntable 2 includes a driving mechanism 21, a main shaft 22, a ratchet 23 and a turntable 24; the base 1 includes a base 11 and a setting The bearing seat 12 on the top of the base 11; the main shaft 22 is vertically connected to the bearing seat 12 through bearings, the ratchet 23 is coaxially connected to the main shaft 22, and the rotating disk 24 is coaxially connected to the upper end of the main shaft 22; The driving mechanism 21 is used to drive the main shaft 22 to rotate; the bearing housing 12 includes an upper bearing housing 121 and a lower bearing housing 122, the ratchet 23 is located above the upper bearing housing 121, and the driving structure is located at the upper bearing housing 121 and the lower bearing housing between the seats 122; the base 1 is hinged with a pawl 13, and the pawl 13 cooperates with the ratchet 23; the end cover position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com