A motor dust and grease cleaning equipment

A technology for cleaning equipment and grease. It is used in metal processing equipment, grinding/polishing equipment, and dust removal. It can solve the problems of complicated cleaning operations and poor cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

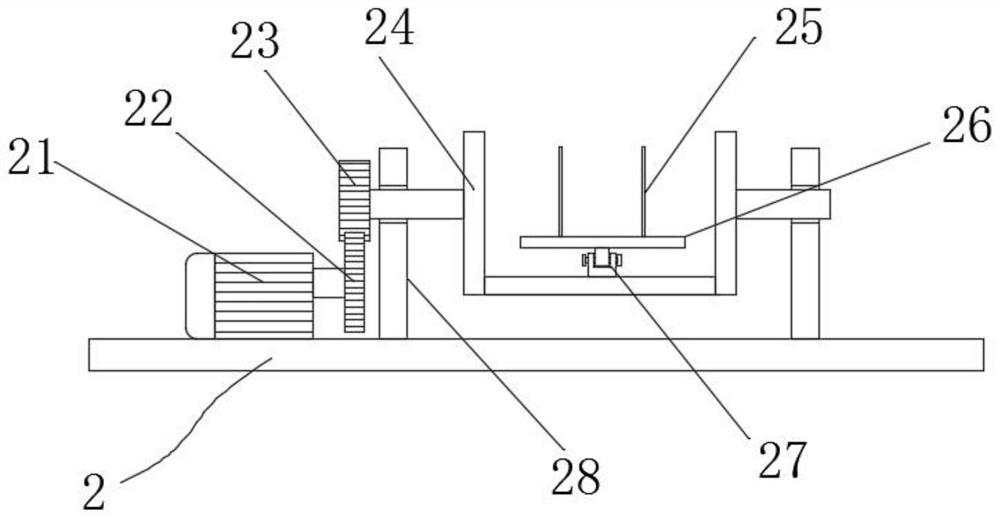

[0032] Such as Figure 1-5 As shown, a motor dust and grease cleaning equipment includes: a support plate 1, a clamping structure 2, a side vertical plate 3, a cleaning structure 4 and a pushing structure 5, and the side vertical plate 3 is vertically fixed on the top of the support plate 1 At one end of the side, the clamping structure 2 is arranged on the top side of the support plate 1, the cleaning structure 4 is arranged on the middle side of the side riser 3, and the pushing structure 5 is fixed on the top of the side riser 3;

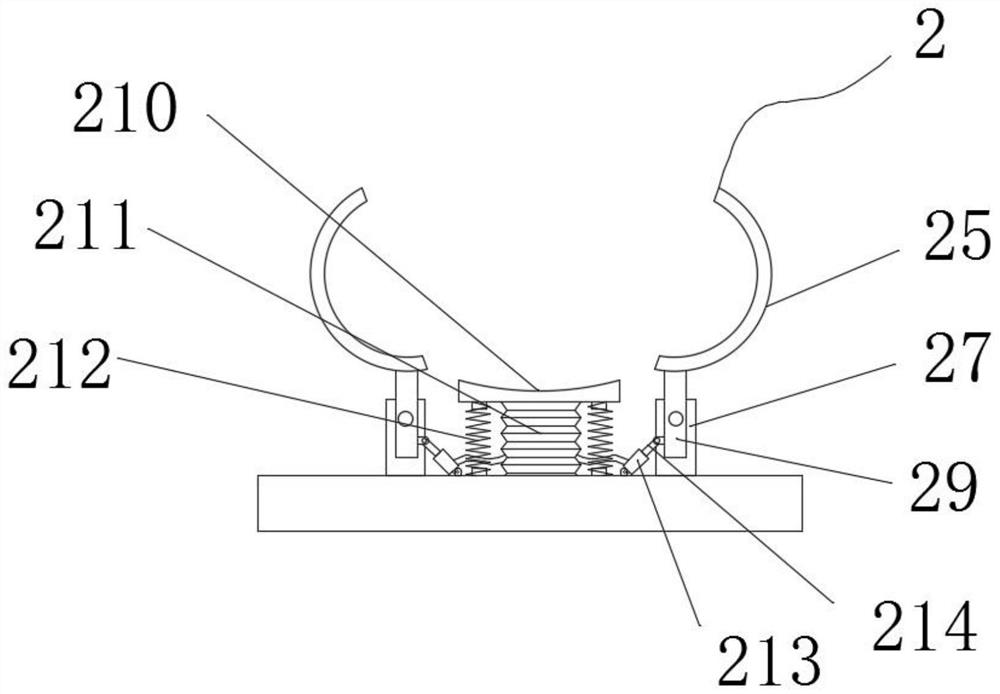

[0033]The clamping structure 2 includes a steering motor 21, a steering gear 22, a matching gear 23, a bogie 24, a clamping rod 25, a horizontal plate 26, a positioning support 27, a fixed frame 28, a swing rod 29, a bottom bracket 210, and an air bag 211, buffer spring 212, air cavity rod 213 and piston rod 214, the steering motor 21 is mounted on the top side of the support plate 1 through bolts, the steering gear 22 is fixed on the output end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com