Hydraulic jig capable of rapidly switching clamping surfaces

A quick-change, hydraulic clamp technology, used in the field of hydraulic clamps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

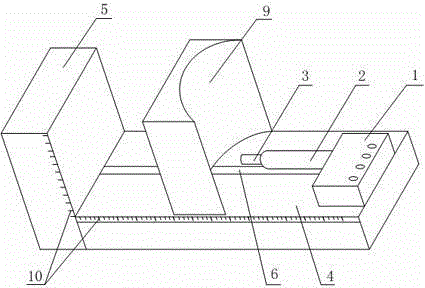

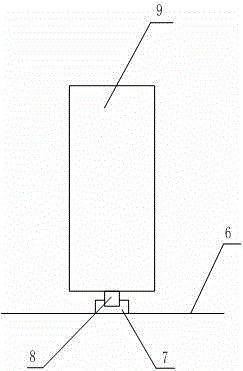

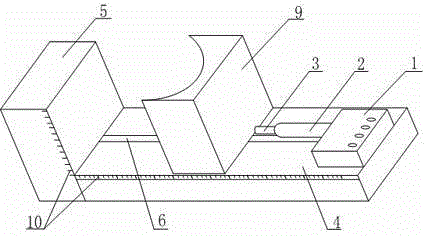

[0017] Such as Figure 1 to Figure 3 The hydraulic clamp with fast switching clamping surface shown includes a base 4, a hydraulic pump 1 arranged on the base 4, a hydraulic cylinder 2 connected to the hydraulic pump 1, and a piston rod connected to the piston inside the hydraulic cylinder 2 3. One end of the base 4 is fixed with a vertical baffle 5, the upper surface of the base 4 is provided with a chute 6, a slider 7 is placed in the chute 6, and a vertical baffle 7 is arranged on the slider 7. A straight rotating shaft 8, on which a clamping plate 9 is fixedly connected, one side of the clamping plate 9 is a plane, and the other side is a curved surface. During the use of this embodiment, the workpiece to be processed is placed at the corner of the base 4 and the baffle 5, the hydraulic pump 1 is started to inject liquid into the hydraulic cylinder 2, the pressure in the hydraulic cylinder 2 rises, and the piston and piston rod are pushed 3 moves forward, the piston rod 3...

Embodiment 2

[0019] Such as Figure 1 to Figure 3 In the shown hydraulic clamp for quickly changing the clamping surface, on the basis of Example 1, the side of the base 4 is provided with a horizontal dimension scale bar 10, and the side surface of the baffle plate 5 is provided with a longitudinal dimension scale bar 10 The chute 6 is set in the middle of the upper surface of the base 4 , and the width of the clamping plate 9 is consistent with the width of the base 4 . The dimension scale bar 10 is used to determine the width and height of the workpiece to be processed, so as to ensure the processing accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com