A method for ball milling to prepare nanoscale powder

A nano-scale powder and ball milling technology, applied in grain processing and other directions, can solve the problems of cumbersome steps, increased ball milling time and energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) First prepare balls with different degrees of softness and hardness. The weight ratio of polyurethane balls to zirconia balls is 1:2, the diameter is 4mm, and the ball-to-material ratio is 3:1; add dispersant and binder, and stir Uniform, the dispersant is a mixture of citric acid and cetyltrimethylammonium bromide with a weight ratio of 1:2, the binder is polyvinyl alcohol, and the amount of the dispersant is 0.4% of the mass of the ITO powder %, the addition of the binder is 1.4% of the mass of the ITO powder.

[0032] 2) Add ITO powder (particle size: 10-30 μm) prepared by chemical co-precipitation method into the ball mill, then perform ball milling, use a mechanical transmission device to drive the grinding tank to perform circular vibration motion, grind at a speed of 1400rpm for 30min, and then cool For 30 minutes, this cycle was repeated 5 times, and ITO nano-powder with a particle size range of 336-502 nm was finally obtained. The obtained ITO nano-powder ha...

Embodiment 2

[0038] 1) First, prepare ball milling balls with different degrees of softness and hardness. The weight ratio of polyurethane balls to zirconia balls is 1:2, the diameter is 5mm, and the ball-material ratio is 2:1; add dispersant and binder, stir evenly, The dispersant is a mixture of citric acid and cetyltrimethylammonium bromide in a weight ratio of 1:2, the binder is polyvinyl alcohol, and the amount of the dispersant is 0.4% of the mass of the tungsten carbide powder , the amount of binder added is 1.4% of the mass of ZTO powder.

[0039] 2) Add ZTO powder (particle size: 10-30μm) into the ball mill, and then perform ball milling, use a mechanical transmission device to drive the grinding tank to perform circular vibration motion, grind at a speed of 1400rpm for 30min, then cool for 30min, and cycle like this for 5 times, and finally The ZTO nanometer powder with a particle diameter ranging from 600 to 800 nm is obtained, and the obtained ZTO nanometer powder has a uniform...

Embodiment 3

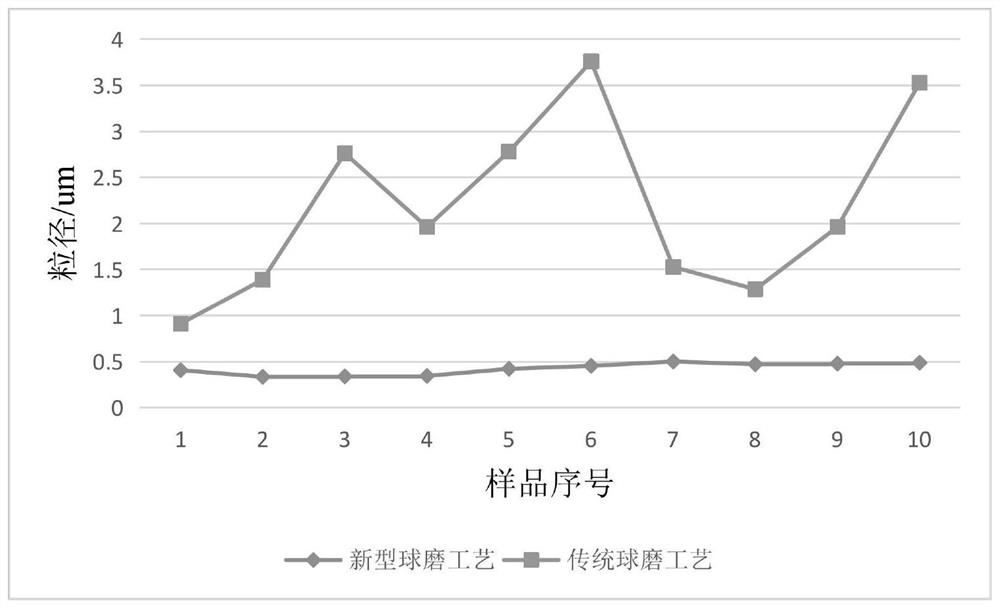

[0044] Using ITO powder with a particle size of 10-30 μm as the raw material powder, ball milling was carried out according to the method in Example 1, and a total of 10 groups of experiments were carried out, numbered 1-10;

[0045] Using ITO powder with a particle size of 10-30 μm as the raw material powder, ball milling was carried out according to the method in Comparative Example 1, and a total of 10 groups of experiments were carried out, numbered 1-10.

[0046] The average particle size of the obtained nano powder material after ball milling is calculated, and the obtained results are as follows figure 2 as shown, figure 2 The new ball milling process represents the product particle size curve obtained by ball milling according to the method of Example 1, and the traditional ball milling process represents the product particle size curve obtained by ball milling according to the method of Comparative Example 1; figure 2 It can be seen that the quality of the nano-po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com