Efficient organic fertilizer granulating device

A granulation device and a technology for organic fertilizers, which are applied in the directions of die extrusion granulation, grain processing, etc., can solve problems such as insufficient crushing, and achieve the effects of good granulation stability, easy promotion and implementation, and convenient and fast granulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

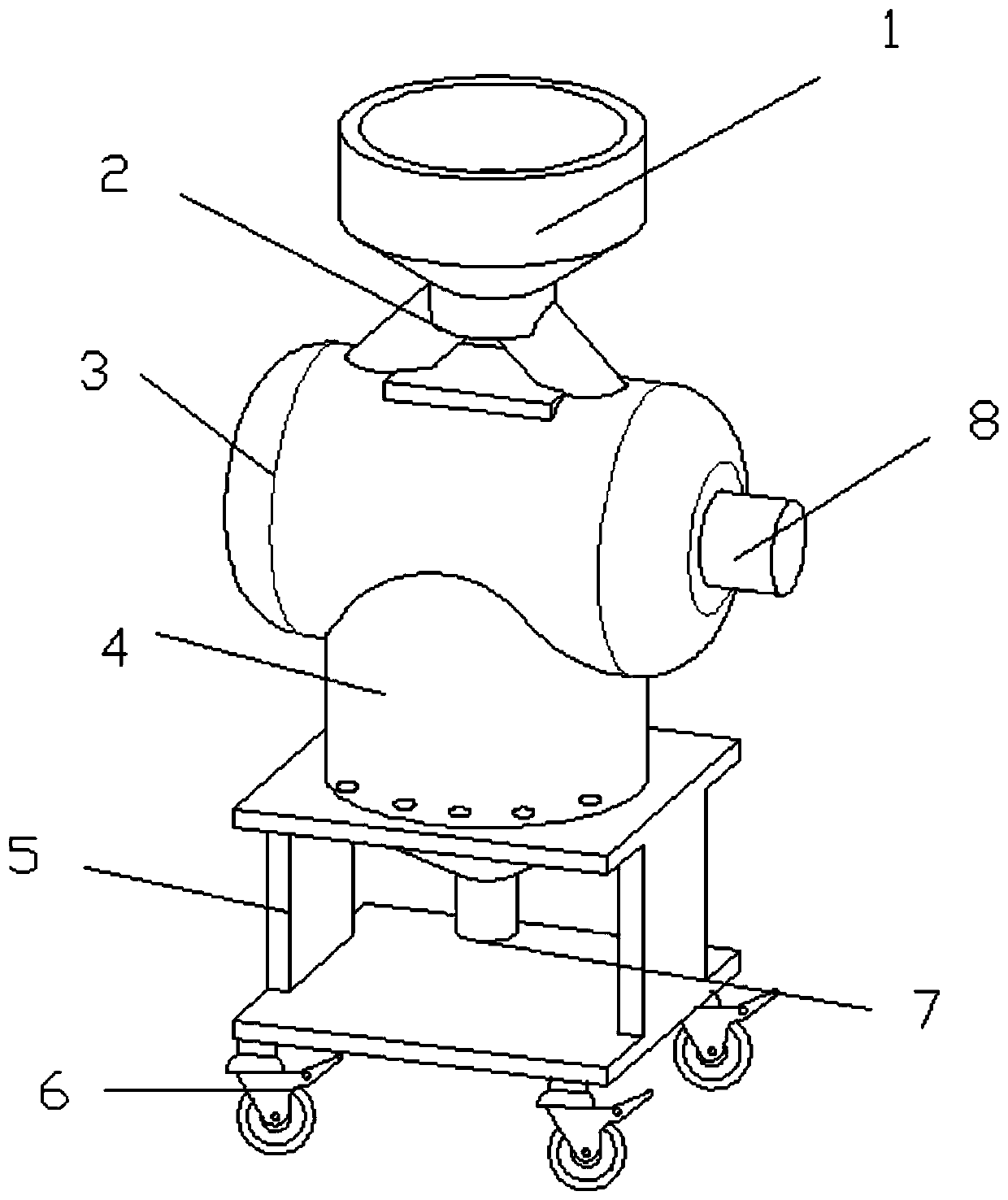

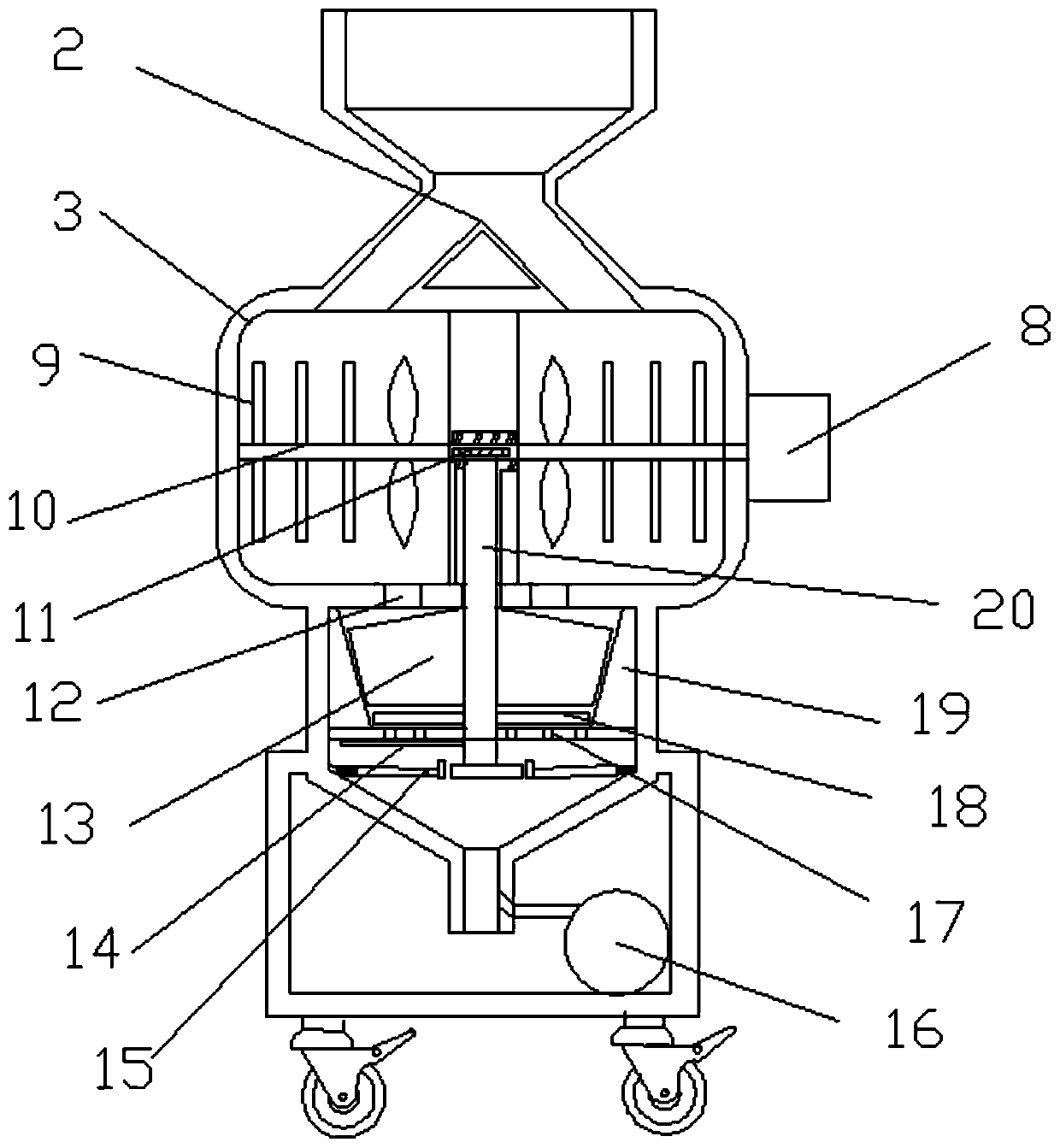

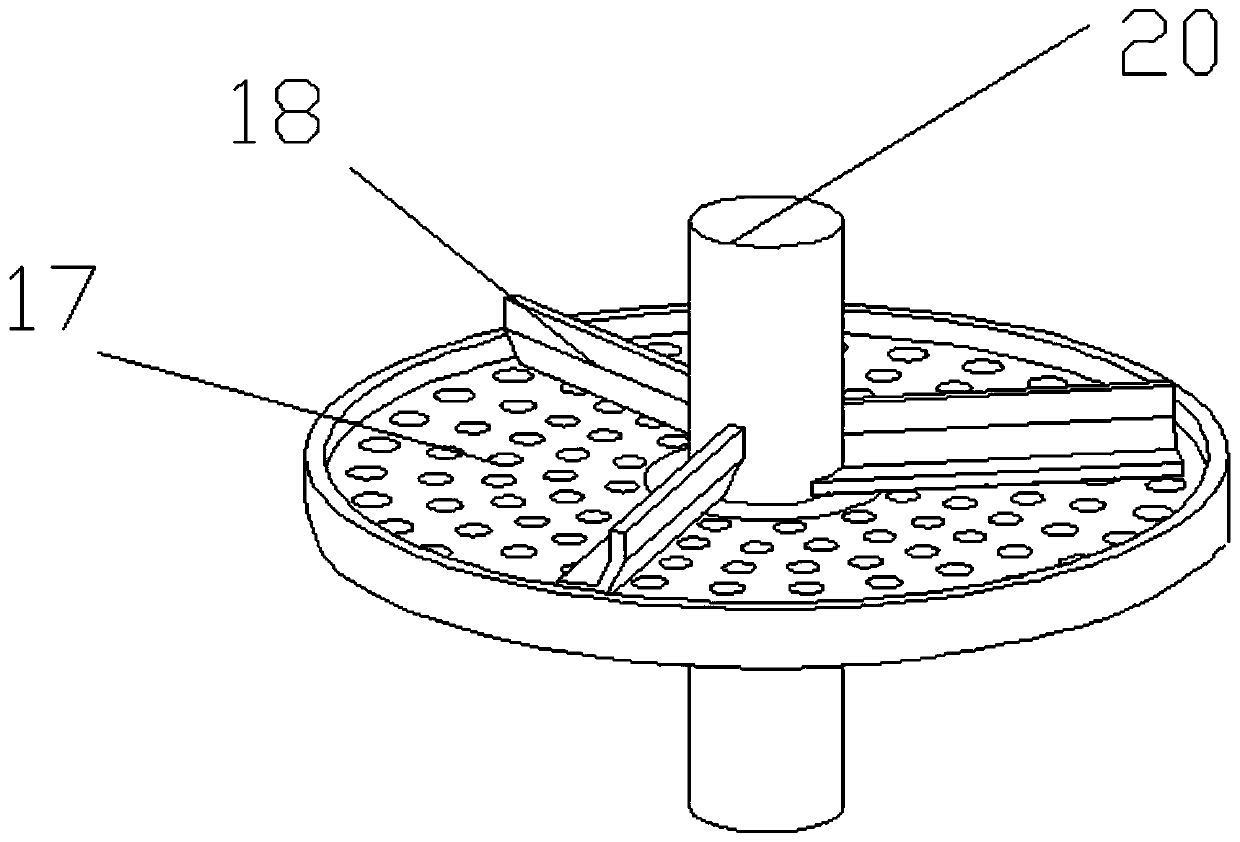

[0025] Please refer to Figure 1-4 , a high-efficiency granulation device for organic fertilizers, comprising a crushing cylinder 3, a granulation cylinder 4 and a mounting frame 5, the crushing cylinder 3 and the granulation cylinder 4 are both cylindrical structures and the crushing cylinder 3 is connected to the manufacturing The top of the capsule body 4 is a T-shaped structure. The bottom of the granulation cylinder 4 is provided with a mounting frame 5, which has a supporting effect on the granulation cylinder 4, and the bottom of the mounting frame 5 is provided with a universal wheel 6, and the universal wheel 6 is provided with a brake assembly. The universal wheel 6 is rotated, and the setting of the universal wheel 6 facilitates the movement and fixing of the device. The top of the crushing cylinder 3 is provided with a feeding hopper 1, and the feeding hopper 1 is connected to the crushing cylinder 3 through the feeding pipe 2. The feeding pipe 2 is an inverted Y-...

Embodiment 2

[0030] On the basis of Embodiment 1, a hot air blower 16 is provided on the mounting frame 5, and the hot air blower 16 is connected to the inside of the discharge port 7. Under the action of the hot air blower 16, hot air enters the inner bottom of the granulation cylinder 4, In this way, the drying of organic fertilizer particles is carried out and the molding is accelerated. The rocking plate 15 is provided with some ventilation holes, so as to facilitate the drying of the organic fertilizer granules when they are formed. Between the grinding sleeve 19 and the granulation plate 17, air holes are opened on the granulation cylinder 4, so as to facilitate the discharge of air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com