A kind of steam cooking equipment and its oven cavity automatic cleaning method

A cooking equipment and automatic cleaning technology, which is applied in the direction of steam cooking utensils, cooking utensils, kitchen utensils, etc., and can solve the problem that the oven cavity is difficult to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

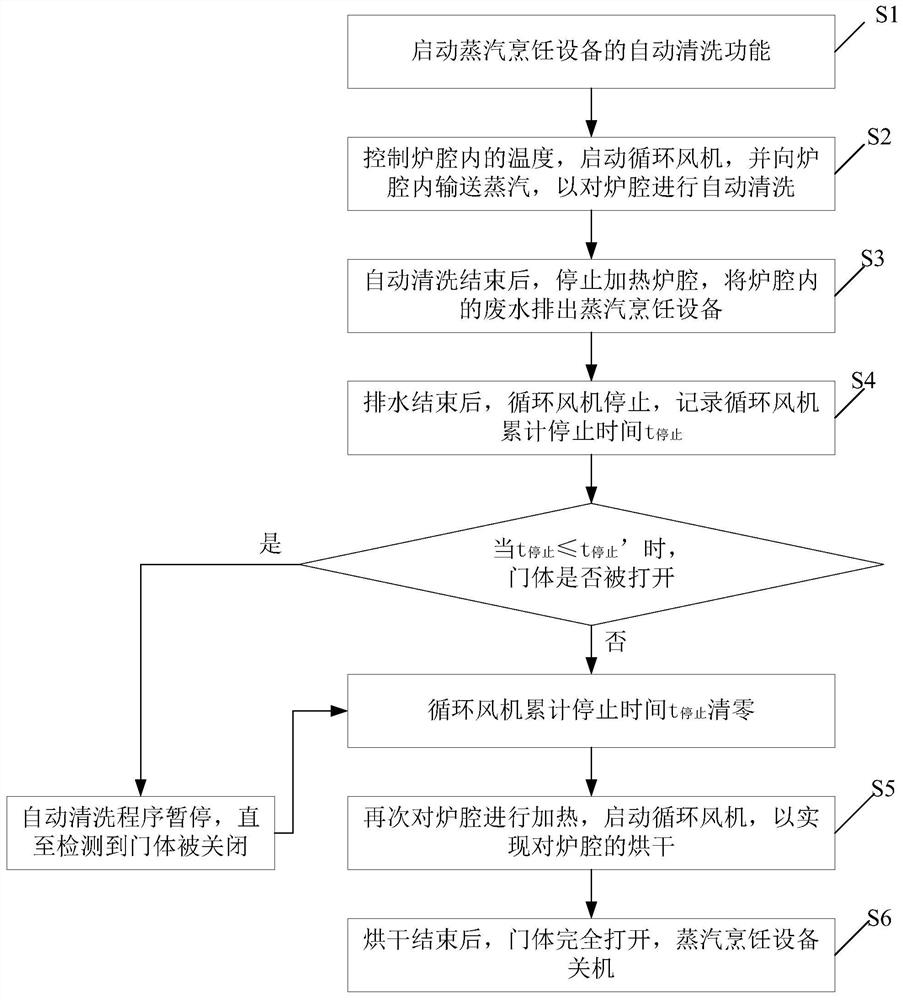

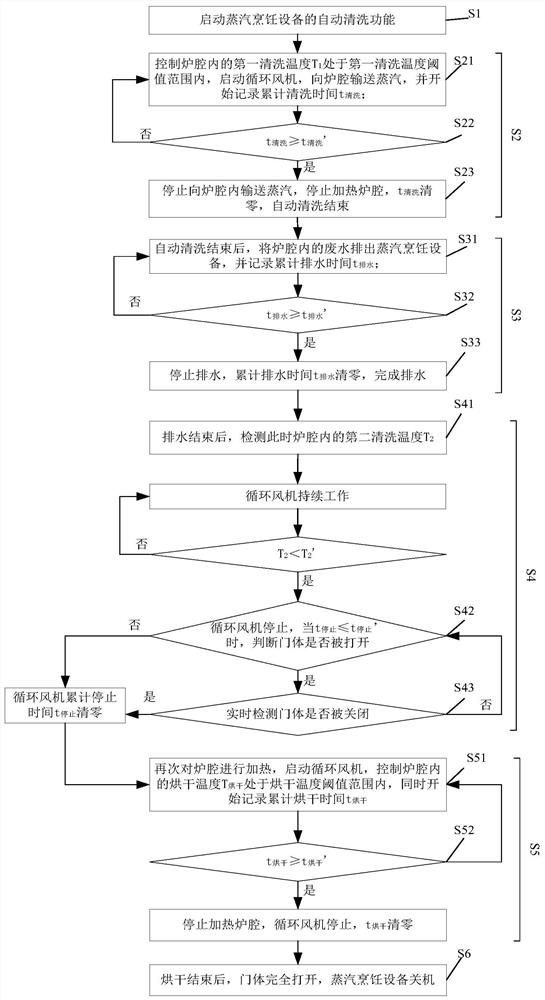

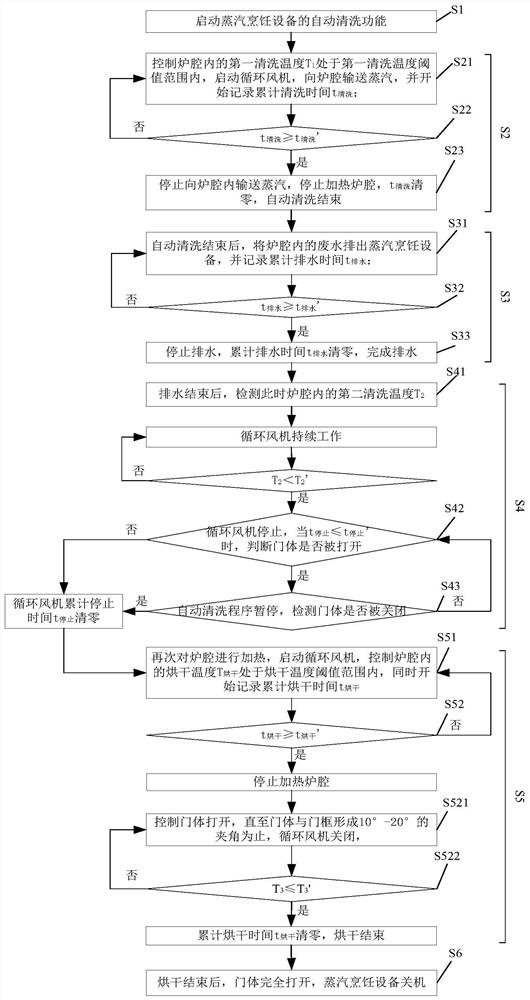

[0063] This embodiment provides a method for automatically cleaning the oven cavity of steam cooking equipment, such as figure 1 As shown, the method includes the following steps:

[0064] S1. Start the automatic cleaning function of the steam cooking equipment;

[0065] S2. Control the temperature in the oven cavity of the steam cooking equipment, start the circulation fan, and deliver steam to the oven cavity to automatically clean the oven cavity;

[0066] S3. After the automatic cleaning is finished, stop heating the oven cavity, and discharge the waste water in the oven cavity to the steam cooking equipment;

[0067] After S4 and S3 are over, turn off the circulating fan, and record the cumulative stop time t of the circulating fan at the same time 停止 , when the cumulative stop time of the circulating fan is t 停止 Satisfied: t 停止 ≤t 停止 ’, judge whether the door is opened, where t 停止 ’ is the cumulative stop time threshold of the circulating fan;

[0068] If so, the ...

Embodiment 2

[0120] A steam cooking device, comprising a heating assembly 1 for heating an oven chamber, a drainage assembly for draining water, a temperature detection element for detecting the temperature of the oven chamber, a timer for recording time, and a timer for driving the The drive assembly for opening the door;

[0121] The heating assembly 1, the drainage assembly, the temperature detection element, the timer and the driving assembly are all electrically connected to the controller of the steam cooking device.

[0122] Because Embodiment 2 adopts the oven chamber self-cleaning method of Embodiment 1, the steam cooking equipment of this embodiment can also solve the problem that the oven chamber of the existing steam cooking equipment is difficult to clean;

[0123] After starting the automatic cleaning function of the steam cooking equipment, the controller controls the heating component 1 to work to heat the oven cavity, and the temperature detection element monitors the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com