An automatic meat beating machine

An automatic, meat-stuffing technology, which is applied in the fields of meat processing, slaughtering, food science, etc., can solve the problems of uneven fiber quality of meat fillings and affect the taste of finished meat fillings, so as to prevent meat fiber breakage and improve product quality and structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

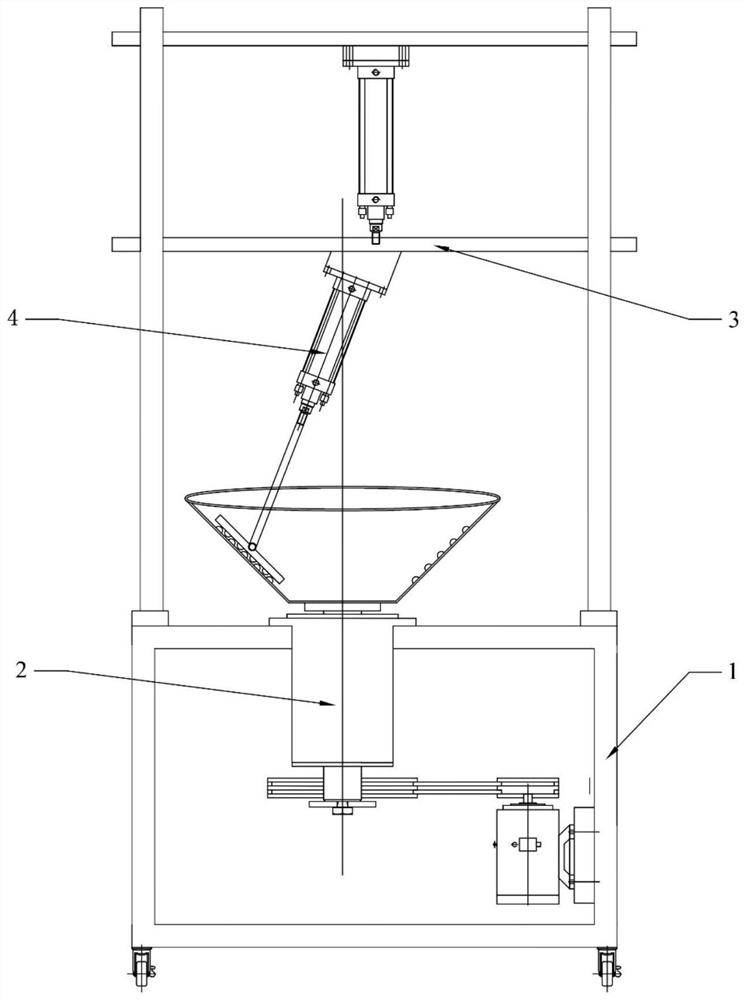

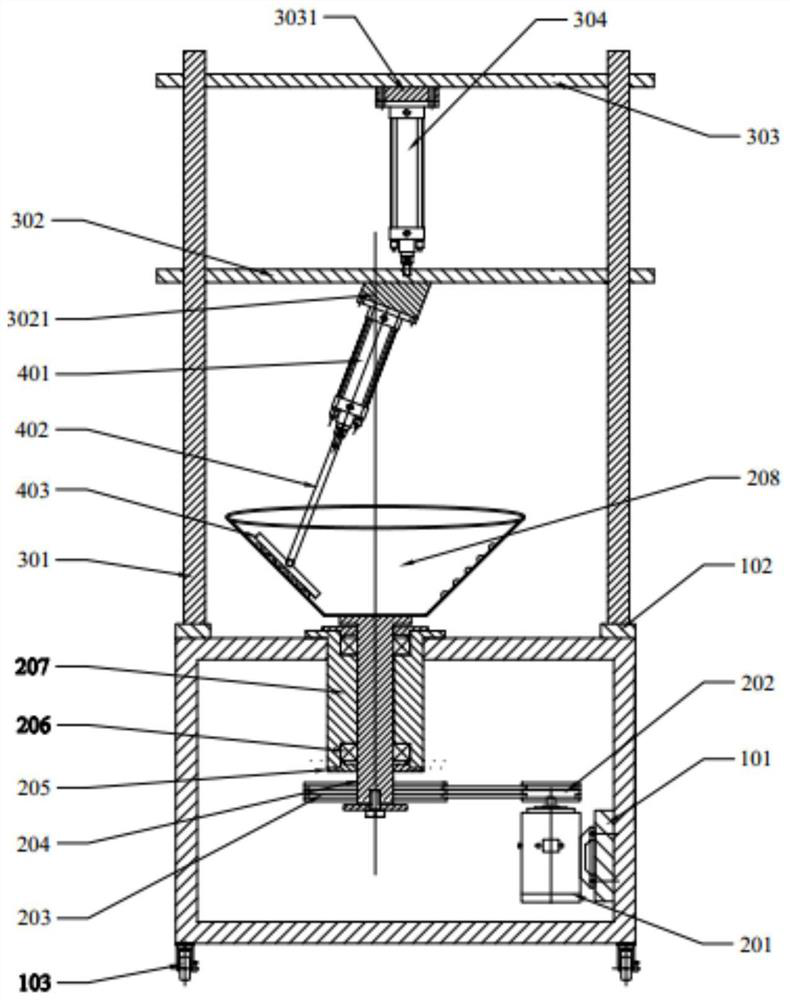

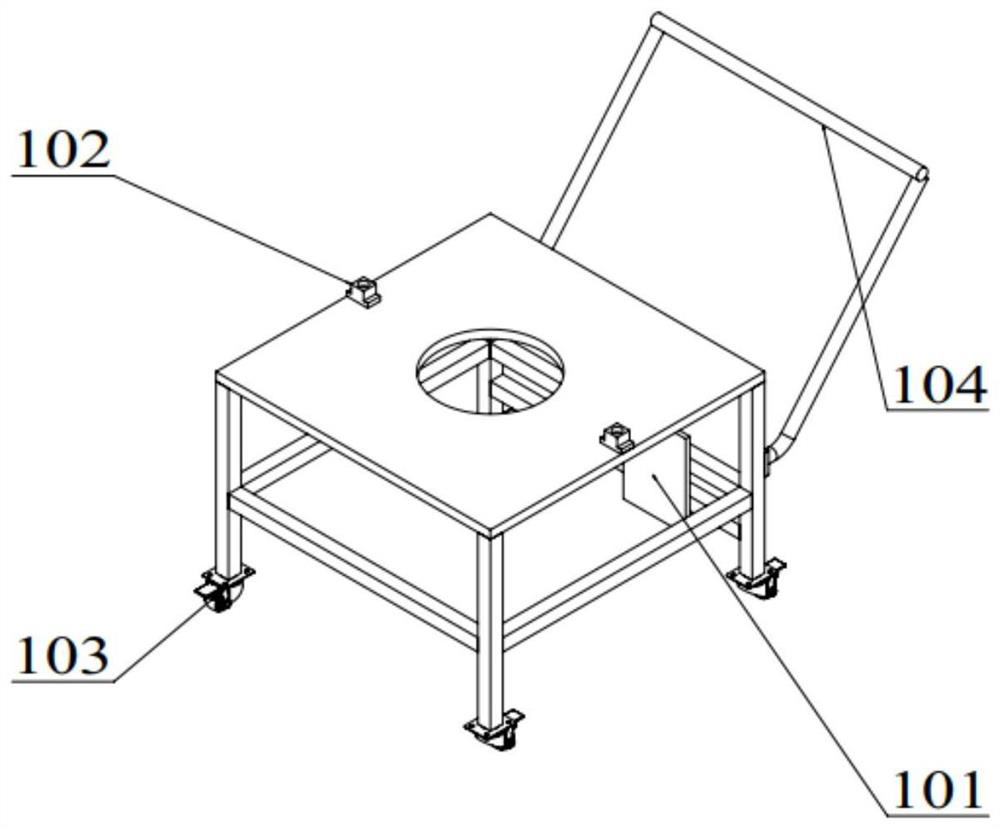

[0039] A meat stuffing automatic beating machine, such as figure 1 As shown, a frame 1 is included, and the frame 1 includes a base that is arranged as a cube at the bottom, and a rotating mechanism 2, a distance adjusting mechanism 3 and a beating mechanism 4 are arranged on the base. For the convenience of transportation, a universal brake caster 103 with feet is provided at the bottom of the base, and a push rod 104 is provided on the whole frame 1, and the push rod 104 is arranged as a rod drawn obliquely from the side of the base. Locking the brakes during the beating process can ensure the stability of the overall equipment; during routine maintenance and cleaning, the push rod 104 on the frame part can facilitate the movement of the equipment.

[0040] Such asfigure 1 with 2 As shown, there are mounting holes on the top of the base for fixing and installing the rotating mechanism 2 . The rotating mechanism 2 adopts a motor 201, and the motor 201 is installed on the si...

Embodiment 2

[0048] The difference from Example 1 is that, as Image 6 As shown, changing the single hammer head 403 into a double hammer head 403 structure connected to the same beating cylinder 401 can increase the beating area and beating efficiency.

[0049] In the above-mentioned embodiments, all the components that can directly contact with the minced meat, such as the hopper 208 and the hammer head 403, are processed and manufactured with food-grade materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com