Novel welding structure health monitoring system and method

A technology of health monitoring system and welding structure, which is applied in measuring devices, material analysis through electromagnetic means, instruments, etc., to achieve high accuracy, real-time and long-term effective monitoring, and simple calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention. The methods used in the present invention are conventional methods unless otherwise specified; the raw materials and devices used are conventional commercially available products unless otherwise specified.

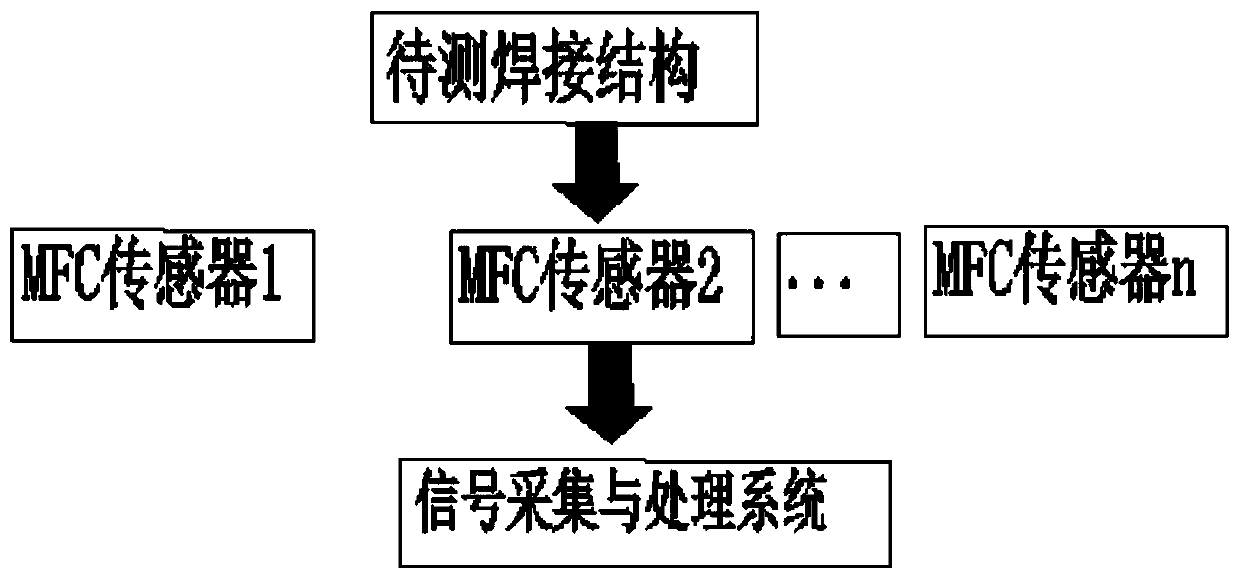

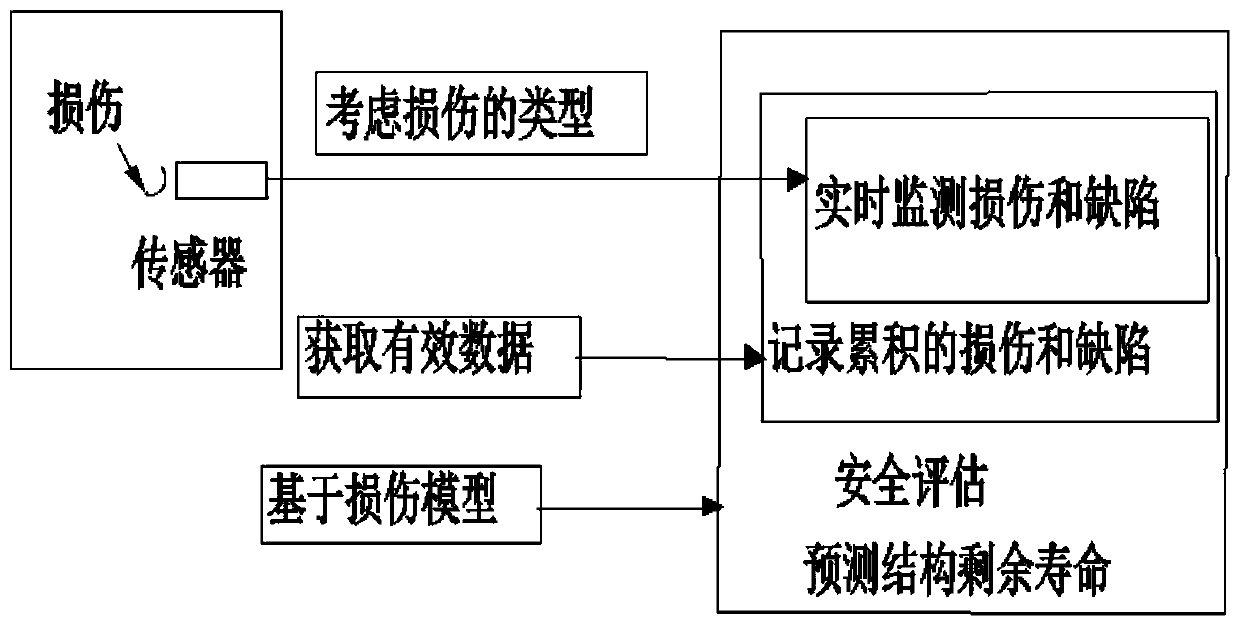

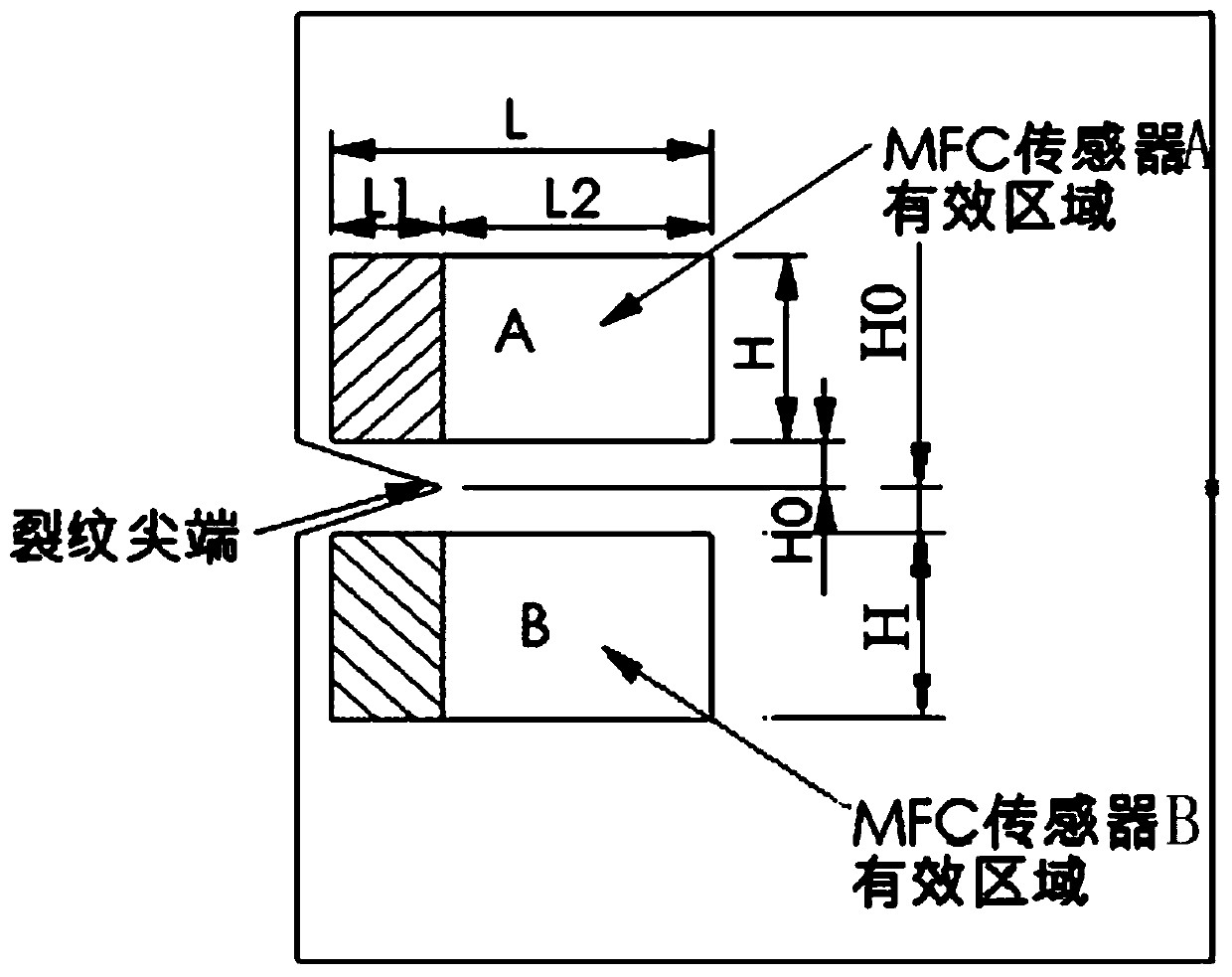

[0047] Such as Figure 1-Figure 2As shown, the present invention provides a new type of welding structure health monitoring system, including MFC sensors and signal acquisition and processing systems electrically connected to each other. MFC sensors can choose the layout density and layout according to actual conditions and accuracy requirements. Collect the strain data around the weld and convert it into a voltage signal, use the signal acquisition and processing system to collect and record the voltage signal output by the MFC sensor and calculate and process it to obtain the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com