Faced concrete outer wall template construction method

A technology of fair-faced concrete and construction method, which is applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connector, formwork/formwork member, etc. The number of repairs is increased, the deviation of the structure size and other problems, to achieve the effect of helping construction management and quality control, saving labor and machine costs, and being conducive to advance customization.

Inactive Publication Date: 2020-04-14

广东恒辉建设集团股份有限公司

View PDF5 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the use of steel formwork has the following obvious disadvantages: (1) Different heights and different curvatures of variable-curvature arc-shaped building structures have different cross-sections, so steel forms with different heights and different curvatures need to be designed, the manufacturing cost is very high, and the manufacturing cycle is long. Templates are usually not reusable, and are not suitable for projects with tight schedules and high cost control requirements

(2) At the variable cross-section of the curved surface, block combination is adopted, and the joint is wide, which is prone to slur

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

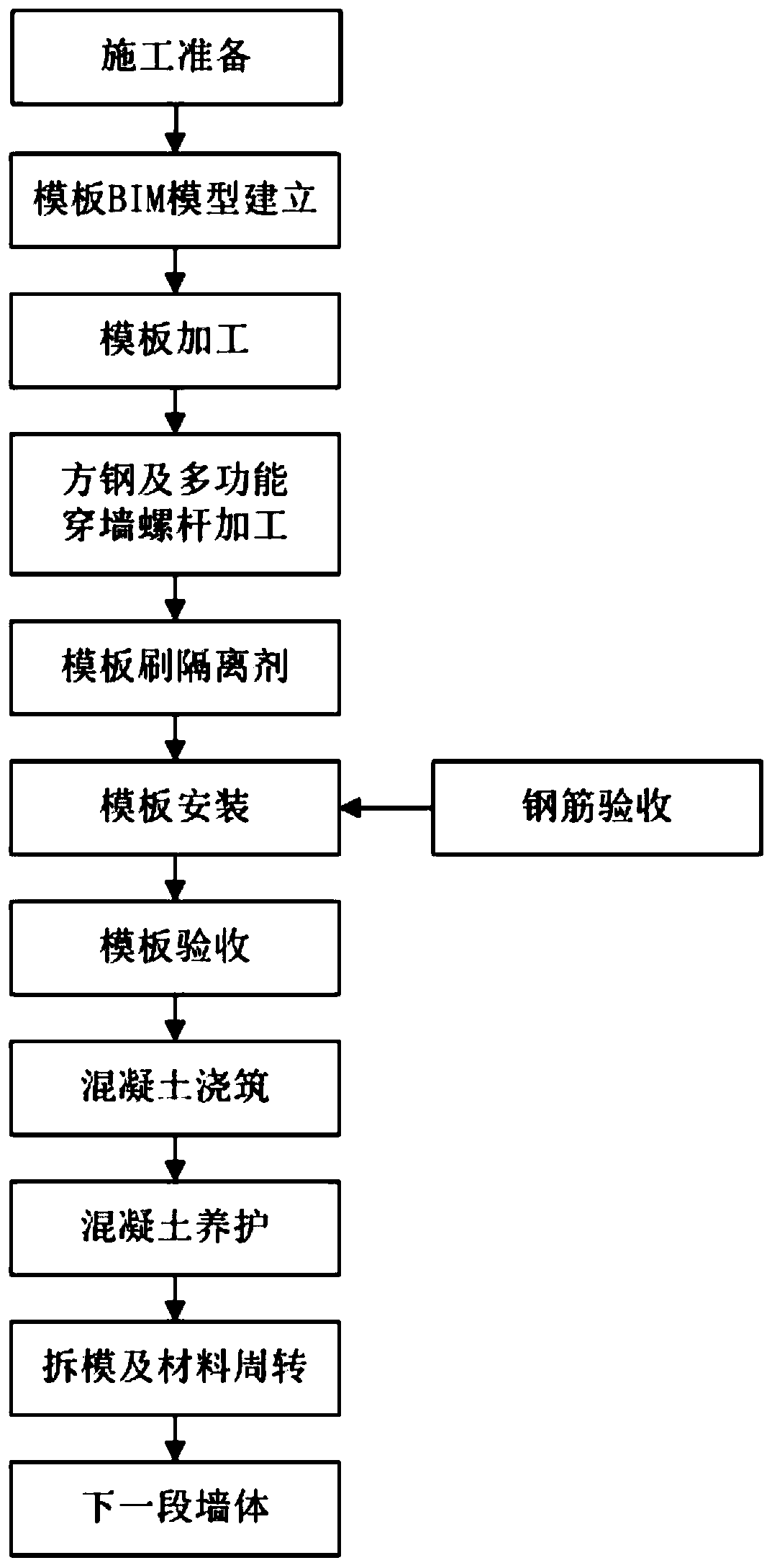

The invention discloses a faced concrete outer wall template construction method in the field of architectural engineering. The faced concrete outer wall template construction method comprises the steps that square steel is selected as back edge materials; the square steel is machined according to different curvatures of arc outer walls in construction drawings, and the machined square steel is numbered to guarantee the square steel in each section position and corresponding arc sections are consistent in curvature; the numbered square steel is correspondingly marked one to one on outer wall template construction diaphragms to guide workers for corresponding mounting through the outer wall template construction diaphragms during reinforcement of templates; wall penetrating screw rod devices are transformed; and according to arc dry wall separation joint requirements, a BIM technology is adopted for deep design of faced concrete templates. Based on a traditional wood template construction process (wood templates, wood braces, steel pipes and split screw systems), template support system materials and tools are transformed, and template machining and mounting process technologies areinnovated.

Description

technical field [0001] The embodiments of the present invention relate to the field of construction engineering, in particular to a construction method of a formwork for an exterior concrete wall. Background technique [0002] The shopping malls, office buildings, public buildings, and residential buildings that have emerged in recent years are constantly unconventional. Their architectural shapes are unique and their visual effects are novel. The traditional rigid facade design is constantly being impacted and replaced by the curved appearance of variable curvature. Generally speaking, the more novel and unique the design of the building, the more it is a challenge and spur to the construction technology; moreover, in order to meet the overall direction of my country's green construction development and reflect the objective needs of green buildings, architectural designers have made clear-faced concrete The use of exterior wall structures is also becoming more common. Howe...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E04G11/08E04G17/065E04G9/04E04G11/12G06F30/13

CPCE04G9/04E04G11/08E04G11/085E04G11/12E04G17/0657

Inventor 李湘泉梁裕忠

Owner 广东恒辉建设集团股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com