Durable antifouling liquid and preparation method thereof

An antifouling liquid and long-lasting technology, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problem of difficult to completely seal the micropores on the surface of the substrate, low storage stability of antifouling liquid, The problem of poor adhesion on the surface of the substrate can achieve good antifouling effect, good storage stability and long-lasting antifouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

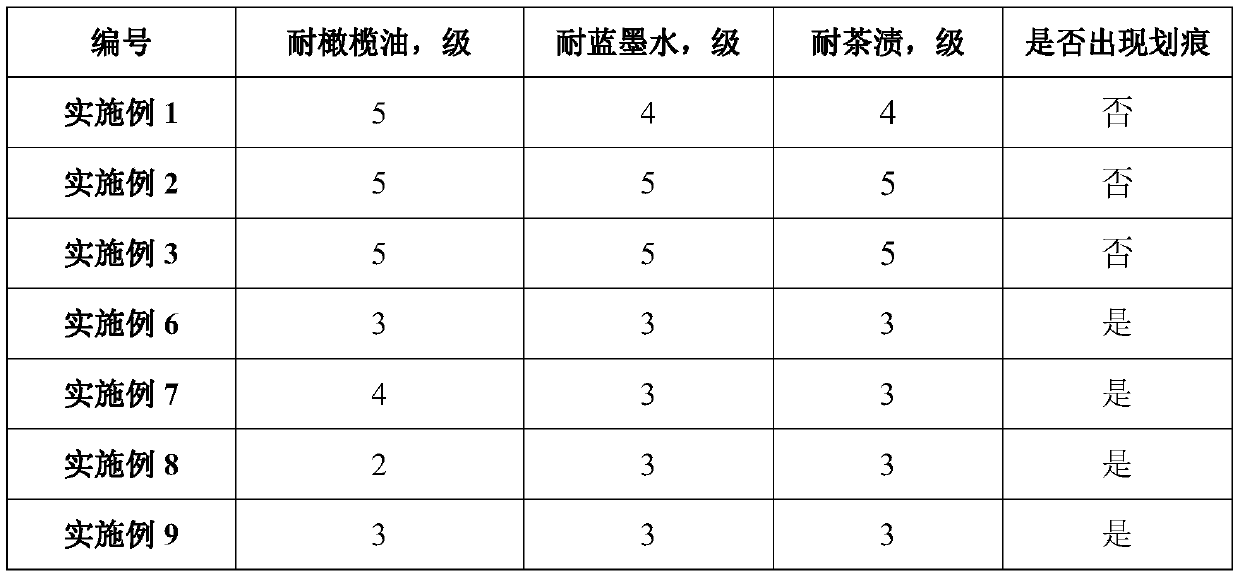

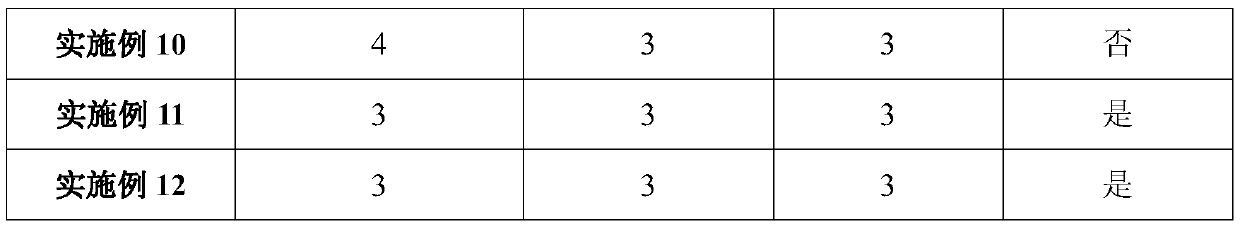

Examples

preparation example Construction

[0036] The second aspect of the present invention provides the preparation method of the above-mentioned durable antifouling liquid, comprising the following steps: adding methylated high-hydrogen-containing silicone oil, low-hydrogen-containing silicone oil, and silica sol to the solvent in sequence under stirring, and stirring for 5- 10 minutes; then continue to add polymer surfactants and sulfonate surfactants into the solvent sequentially under stirring, and stir for 5 to 10 minutes; finally add stabilizers to make the pH of the solution system in the range of 7 to 9 Stir for at least 30 minutes to obtain the durable antifouling solution.

[0037] The applicant unexpectedly found that by adding a stabilizer to the antifouling liquid, the film-forming speed of the antifouling liquid on the surface of the substrate can be regulated, and the storage stability of the antifouling liquid with different pH values is different. When the pH is between 7 and 9 When the concentrati...

Embodiment 1

[0041] This embodiment provides a long-lasting antifouling liquid. According to parts by weight, the raw materials of the antifouling liquid include 20 parts of high hydrogen-containing methyl silicone oil, 5 parts of silicone oil with low hydrogen content, 5 parts of silica sol, and 50 parts of ethyl acetate. Parts, 8 parts of surfactant, tartaric acid; Wherein silica sol is the silica sol that average particle diameter is 13~17nm, the mixture of silica sol that average particle diameter is 26~34nm and the silica sol that average particle diameter is 58~65nm, three The weight ratio of the two is 1:2:1; the surfactant is sodium polyacrylate and diisooctyl sodium sulfosuccinate, and the weight ratio of the two is 3:1.

[0042] This embodiment also provides the preparation method of the anti-fouling liquid, which includes the following steps: adding methylated high-hydrogen-containing silicone oil, low-hydrogen-containing silicone oil, and silica sol to the solvent in sequence un...

Embodiment 2

[0044] This embodiment provides a long-lasting antifouling liquid. According to parts by weight, the raw materials of the antifouling liquid include 35 parts of high hydrogen-containing methyl silicone oil, 10 parts of silicone oil with low hydrogen content, 12 parts of silica sol, and 70 parts of ethyl acetate. Parts, 22 parts of surfactant, tartaric acid; Wherein silica sol is the silica sol that average particle diameter is 13~17nm, the mixture of silica sol that average particle diameter is 26~34nm and the silica sol that average particle diameter is 58~65nm, three The weight ratio of the two is 1:2:1; the surfactant is sodium polyacrylate and diisooctyl sodium sulfosuccinate, and the weight ratio of the two is 3:1.

[0045] This embodiment also provides the preparation method of the anti-fouling liquid, which includes the following steps: adding methylated high-hydrogen-containing silicone oil, low-hydrogen-containing silicone oil, and silica sol to the solvent in sequence...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com