Heat-conducting silica gel as well as preparation method and application thereof

A heat-conducting silicon and gel technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve problems such as mixing difficulties, increased viscosity of thermal gel systems, and reduced production efficiency, and achieve improved contact area and anti-settling properties Good, the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

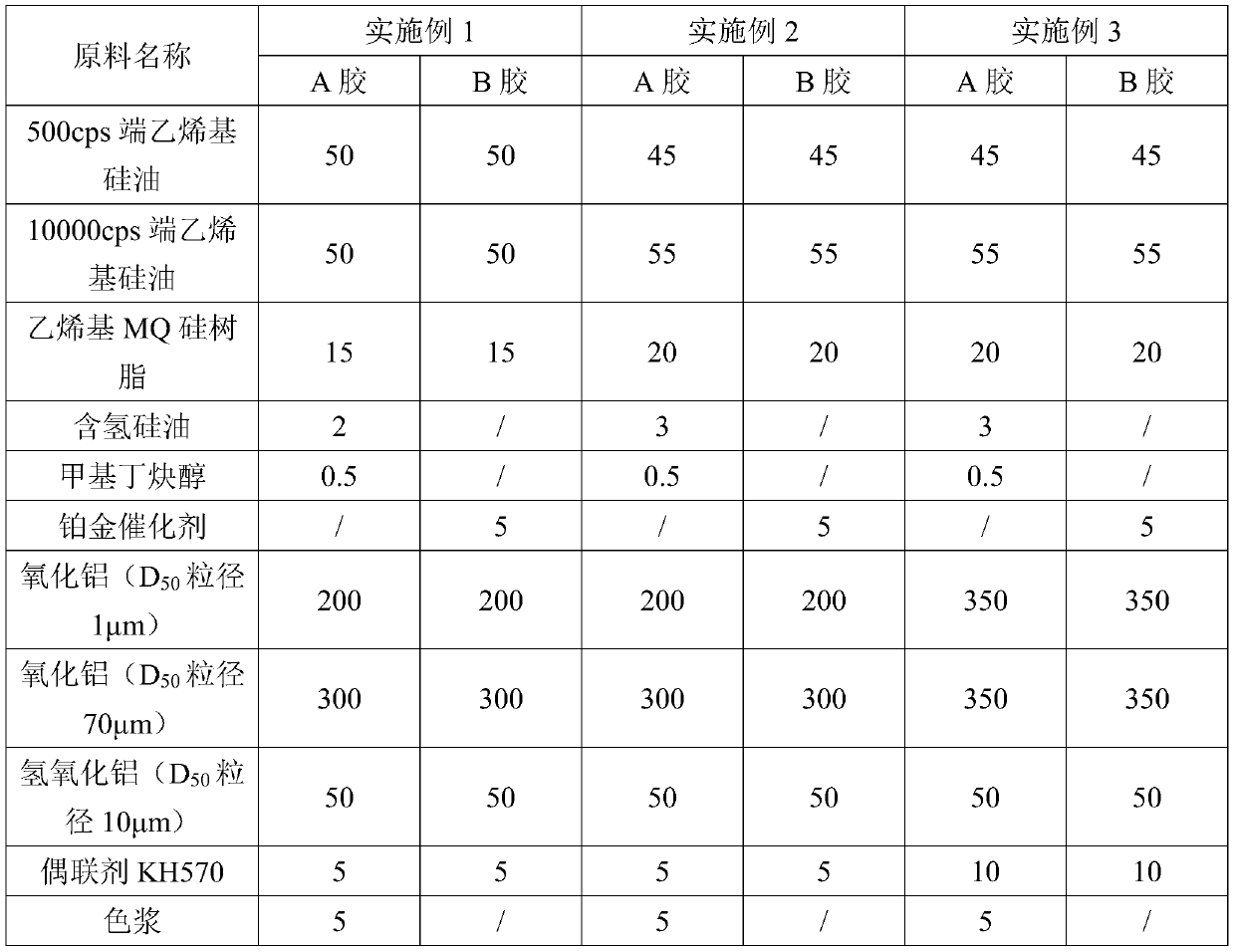

[0074] Embodiments 1-3 each provide a thermally conductive silicone gel, which includes glue A and glue B, the mass ratio of glue A to glue B is 1:1, and the types and amounts (parts by weight) of the specific components are shown in Table 1 below .

[0075] The preparation method of above-mentioned heat-conducting silicone gel is as follows:

[0076] (1) Add the thermally conductive fillers and coupling agents of glue A and glue B into a high-speed mixer, stir for 30 minutes at 20°C at a rate of 1000r / min, and perform surface activation treatment to obtain surface activated thermally conductive fillers;

[0077] (2) Add the surface-activated thermally conductive filler obtained in step (1) to the double planetary mixer in proportion to other components in glue A and glue B, and stir for 120 minutes at 25°C at a speed of 25r / min to form A Glue and B glue were vacuum defoamed to obtain the thermally conductive silicone gel.

[0078] Table 1

[0079]

Embodiment 4-6

[0081] Embodiments 4-6 each provide a thermally conductive silicone gel, which includes glue A and glue B, the mass ratio of glue A to glue B is 1:1, and the types and amounts (parts by weight) of the specific components are shown in Table 2 below .

[0082] The preparation method of above-mentioned heat-conducting silicone gel is as follows:

[0083] (1) Add the thermally conductive fillers and coupling agents of glue A and glue B into a high-speed mixer, stir for 20 minutes at 25°C at a speed of 800r / min, and perform surface activation treatment to obtain surface activated thermally conductive fillers;

[0084] (2) Add the surface-activated thermally conductive filler obtained in step (1) to the double planetary mixer in proportion to other components in glue A and glue B, and stir for 100 minutes at 30°C at a speed of 30r / min to form A Glue and B glue were vacuum defoamed to obtain the thermally conductive silicone gel.

[0085] Table 2

[0086]

Embodiment 7-9

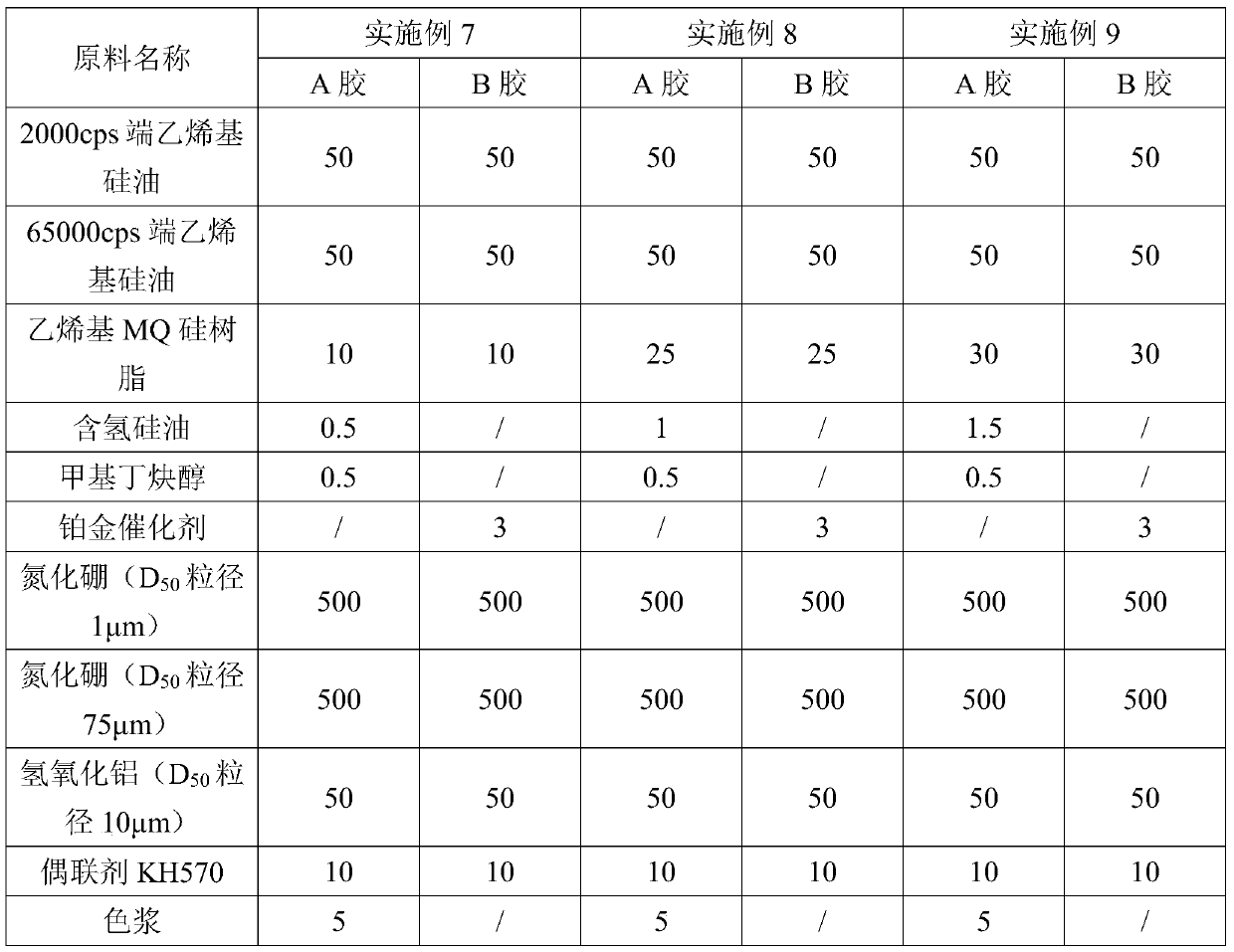

[0088] Embodiments 7-9 each provide a thermally conductive silicone gel, which includes glue A and glue B, the mass ratio of glue A to glue B is 1:1, and the types and amounts (parts by weight) of the specific components are shown in Table 3 below .

[0089] The preparation method of above-mentioned heat-conducting silicone gel is as follows:

[0090](1) Add the thermally conductive fillers and coupling agents of glue A and glue B into a high-speed mixer, stir at 30°C and 500r / min for 25min, and perform surface activation treatment to obtain surface activated thermally conductive fillers;

[0091] (2) Add the surface-activated thermally conductive filler obtained in step (1) to the double planetary mixer in proportion to other components in glue A and glue B, and stir for 60 minutes at 35°C at a speed of 40r / min to form A Glue and B glue were vacuum defoamed to obtain the thermally conductive silicone gel.

[0092] table 3

[0093]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com