Application of copper tailings heap leaching waste residue, vegetation composite substrate and preparation method

A composite base material and copper tailings technology, which is applied in the field of vegetation composite base material and its preparation, and the application of copper tailings heap leaching waste residue, can solve the problem of increasing the land occupation of the same tailings, increasing the economic burden of the enterprise, and the depletion of surrounding vegetation, etc. problem, to achieve the effect of realizing reuse and recycling, facilitating coordinated development, and good ammonia nitrogen removal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084] According to a third aspect of the present invention, the present invention provides a method for preparing the above-mentioned vegetation composite substrate, comprising the steps of:

[0085] Portland cement, copper tailings heap leaching waste residue, lime, zeolite powder, peat soil, optional polyvinyl alcohol, optional hydrogen peroxide and water are evenly mixed, then poured into a mold to form, molded, and dried to obtain Vegetated composite substrates.

[0086] The preparation method of the vegetation composite base material provided by the invention has the advantages of simple process, convenient operation, easy realization of industrialized large-scale production, and further reduction of preparation cost.

[0087] In a preferred embodiment of the present invention, in terms of parts by mass, in the process of preparing the vegetation composite substrate, the amount of water added is 20-25 parts, preferably 22-24 parts.

[0088] In the process of preparing t...

Embodiment 1

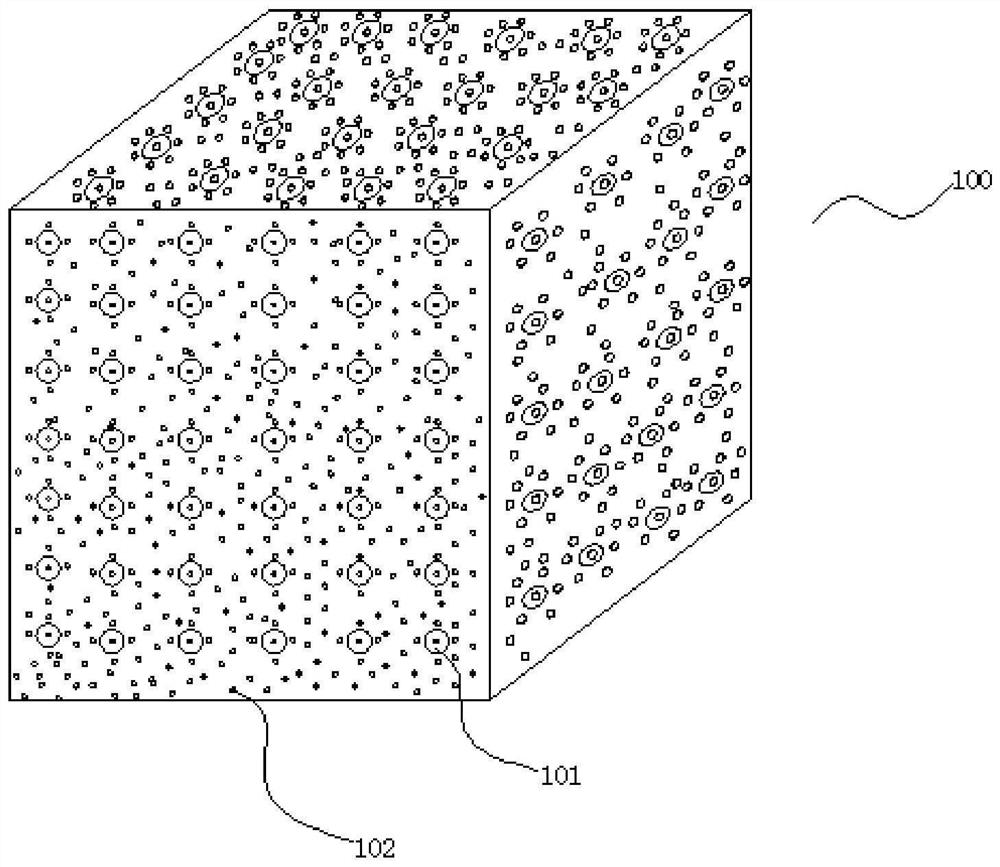

[0120] like figure 1 As shown, the present embodiment provides a vegetation composite substrate 100, the vegetation composite substrate 100 is formed with a plurality of continuously superimposed holes, the holes include large holes 101 and small holes 102, and the small holes 102 are arranged in the large holes 101 In the center and / or around the center, the large hole 101 and the small hole 102 communicate with each other to form internal pipelines for plant growth to store water, repel water, and keep water.

[0121] In this embodiment, the small hole 102 is arranged in the center and / or around the large hole 101, which means that the small hole 102 can be arranged in the center of the large hole 101, or can be arranged around the large hole 101, and can also include multiple Some of the small holes 102 are set in the center of the big hole 101 , and some of the small holes 102 are set around the big hole 101 .

[0122] In this embodiment, the vegetation composite substrat...

Embodiment 2

[0128] This embodiment provides a vegetation composite base material, its structure is as embodiment 1, and the vegetation composite base material provided by this embodiment includes the following raw materials in parts by mass: 35 parts of 42.5 ordinary Portland cement, copper tailings 50 parts of heap leaching waste residue, 5 parts of free lime, 5 parts of zeolite powder, 3 parts of peat soil, 0.5 part of polyvinyl alcohol, wherein the particle size of copper tailings heap leaching waste residue is 200 mesh, and the particle size of free lime is 200 mesh, The particle size of zeolite ash is 200 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com