IGBT (Insulated Gate Bipolar Translator) inversion non-gas-shielded welding machine

A gas shielding and welding machine technology, applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problems of less protection function, low reliability of circuit operation, high product manufacturing cost and sales price, and achieves less connection control lines. , The effect of simplifying the production process and improving the market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

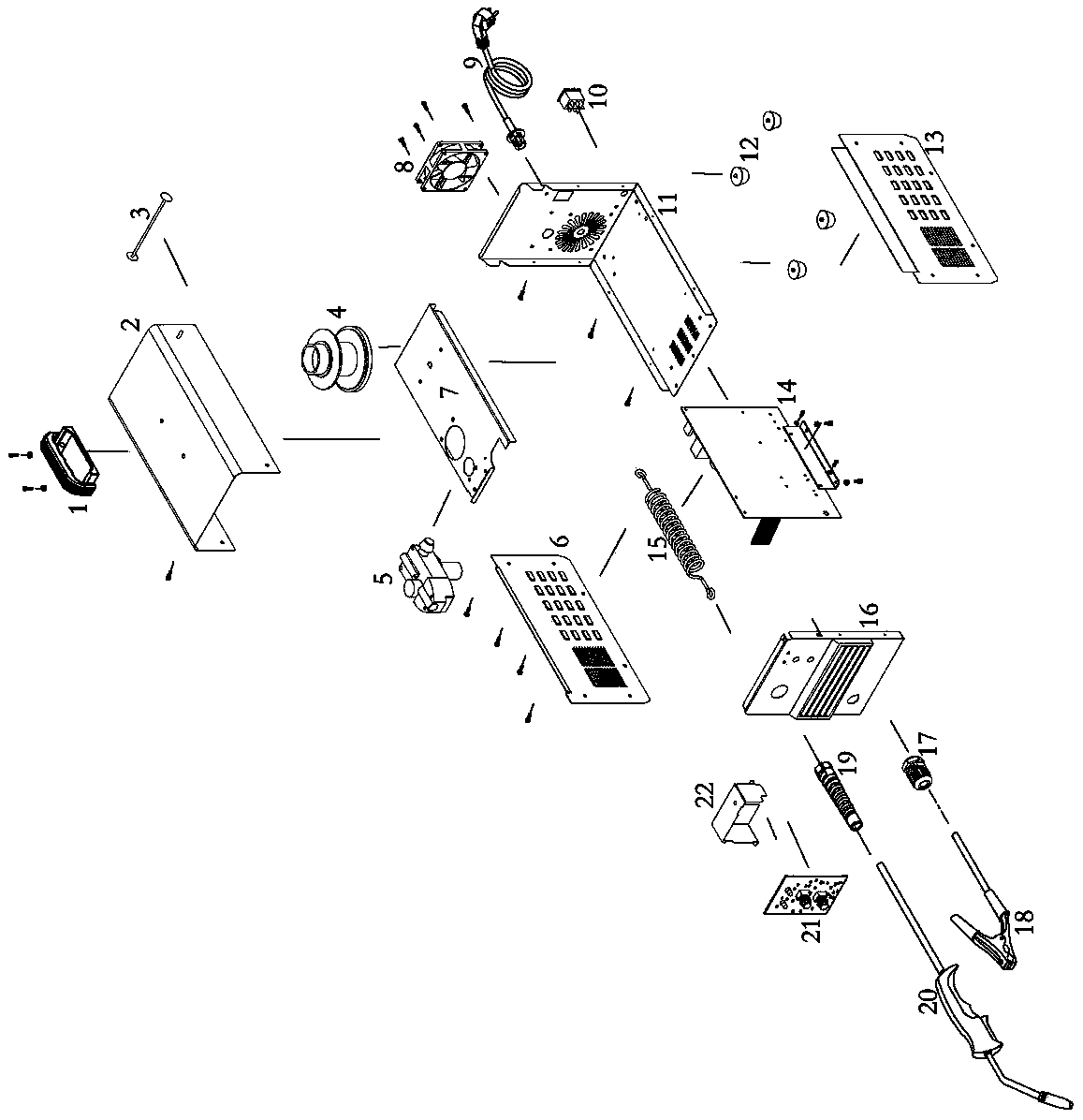

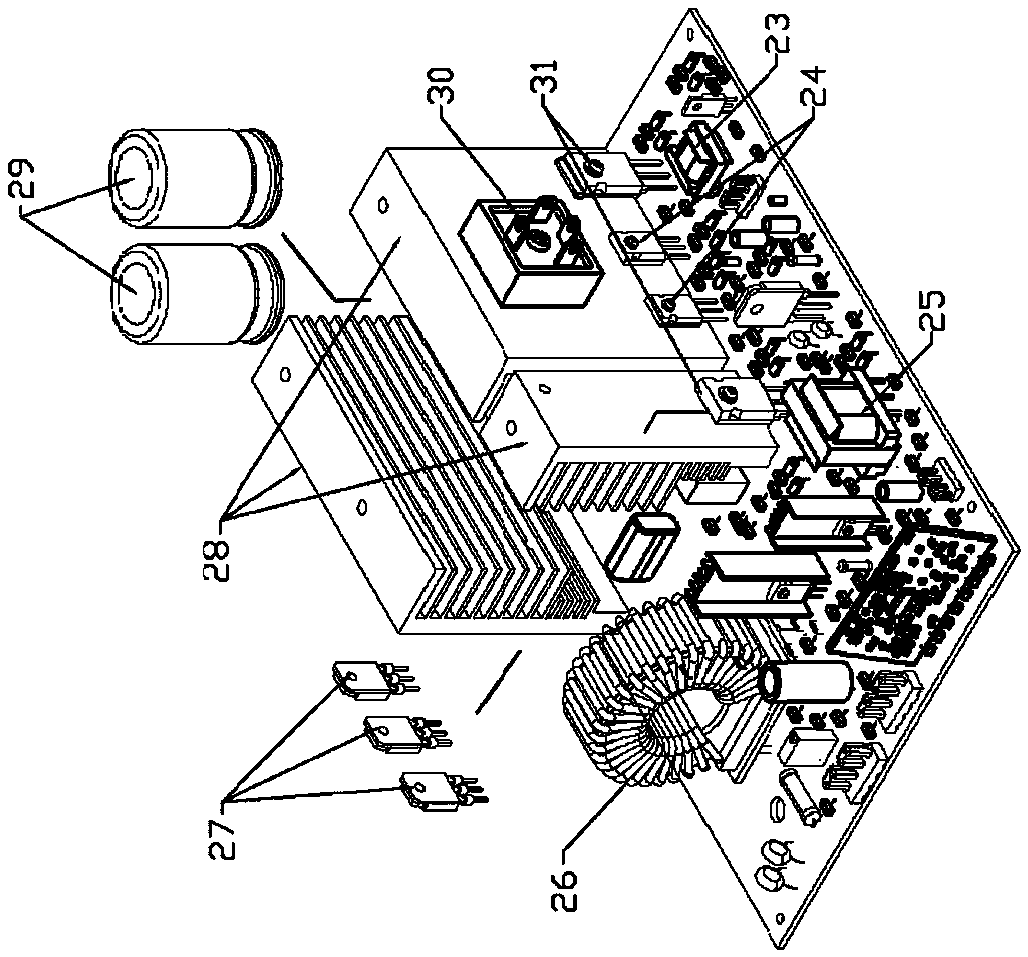

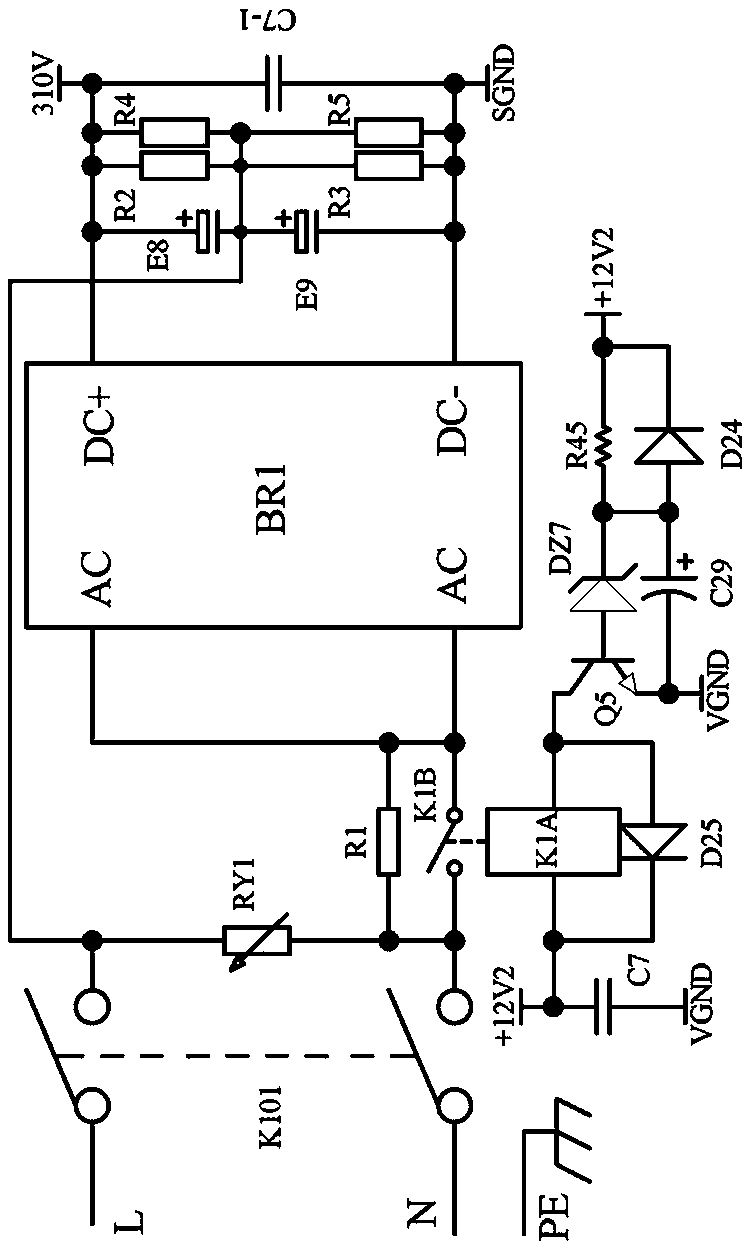

[0029] Such as Figure 1-7 It is a structural design schematic diagram of a welding machine for IGBT inverter gas-shielded flux-cored wire welding made by the present invention; the main components of the welding machine include:

[0030] 1) Shell part. It includes a handle 1 , an upper cover 2 of the casing, a left cover 6 , a bottom 11 of the casing, a right cover 13 , and a front panel 16 of the casing.

[0031]2) Rear panel part. The parts installed on the rear panel of the welder casing bottom plate 11 of the present invention mainly include: a power switch 10, a power supply line and its wire fixer 9, and a cooling fan 8. Connect to the power supply grid through the power line 9. The power switch 10 controls the on or off of the input power. Cooling fan 8 carries out forced air cooling to some parts inside the welding machine. The cooling fan is located at the rear of the power supply, and the cold air enters from the air inlet at the rear of the welding machine cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com