Motor starter for synchronous machine

A synchronous motor and electric motor technology, applied in the starter of a single synchronous machine, the starter of a single reluctance motor, electric/electric converter, etc., can solve the problem of insufficient torque, switching power loss, and reduce hardware complexity And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

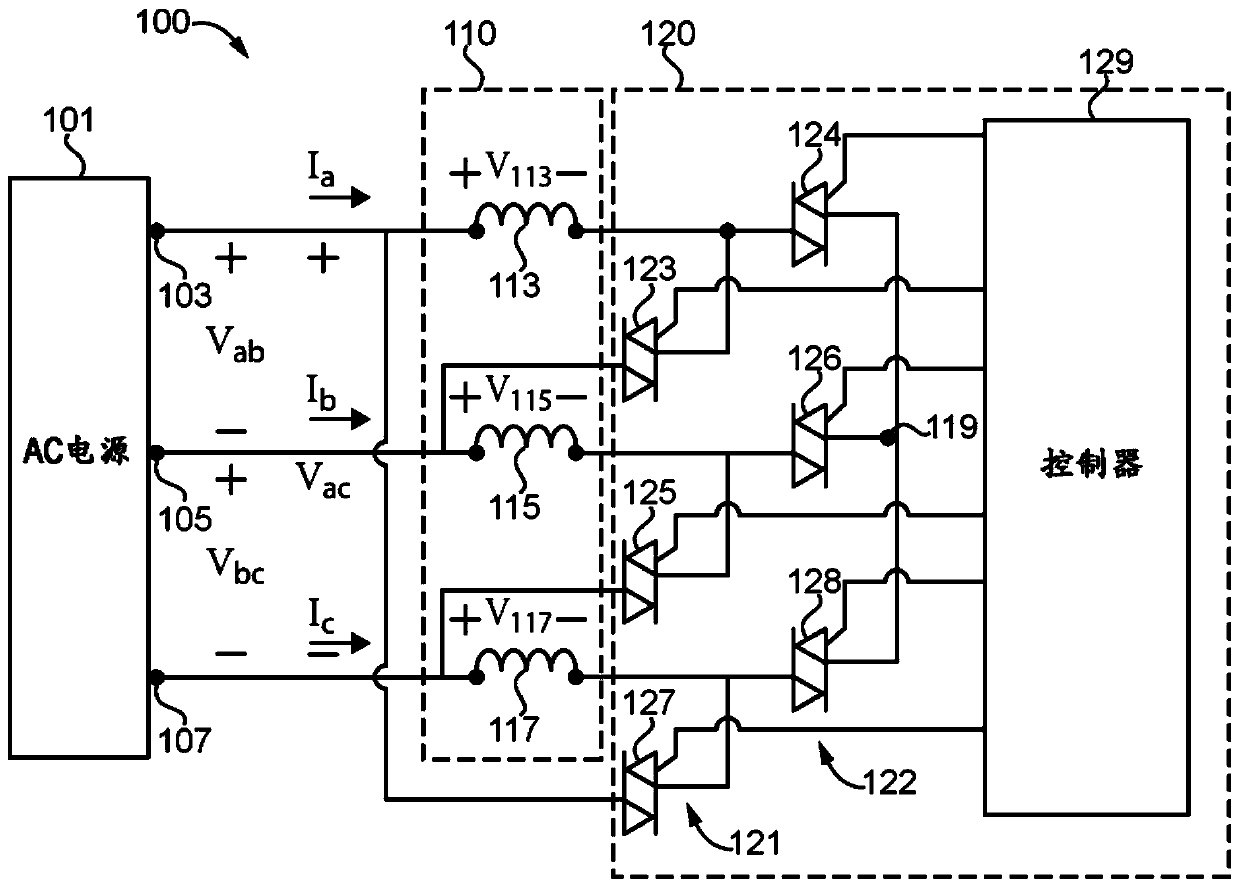

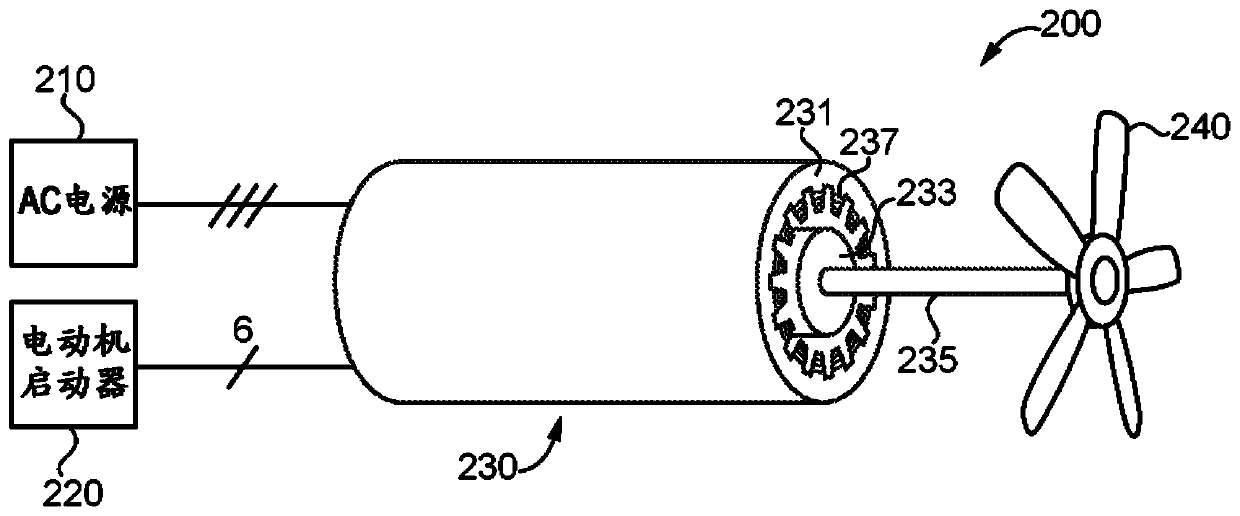

[0011] refer to figure 1 , an exemplary synchronous motor starting system 100 including a motor starter 120 is shown. The system 100 is configured to operate at synchronous speed while being coupled to a high moment of inertia load. In certain embodiments, the high moment of inertia is defined by the critical inertia values for induction motors in the NEMA MG-1 standard. In certain embodiments, the high moment of inertia is one-tenth of the critical inertia value of the NEMAMG-1 standard. It should be appreciated that synchronous motor starting system 100 (sometimes referred to as system 100 ) may be implemented in a variety of high moment of inertia load applications, including fans, fan walls, centrifuges, or conveyors, just to name a few examples. Furthermore, the illustrated embodiments are not intended in any way to limit the application of the example motor starter 120 to a subset of synchronous motors or AC power sources based on the electrical or mechanical charac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com