Hydrate generation, decomposition and blockage mechanism visual simulation device and method

A technology for hydrate formation and simulation devices, which is applied in teaching models, educational tools, instruments, etc., can solve the problems of large space occupation, expensive equipment, and large investment in equipment, so as to increase flow intensity, reduce workload, and reduce energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

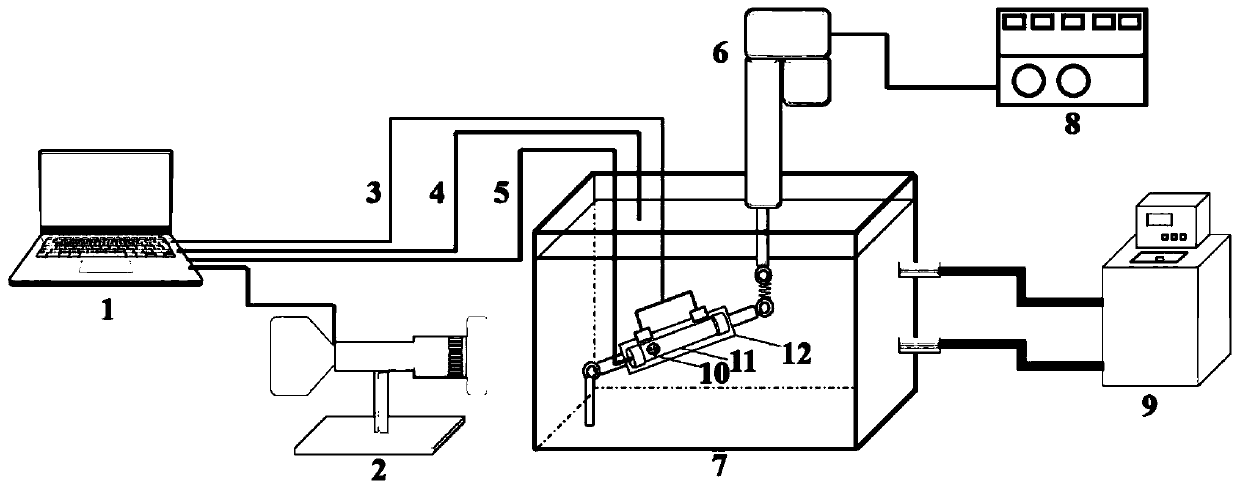

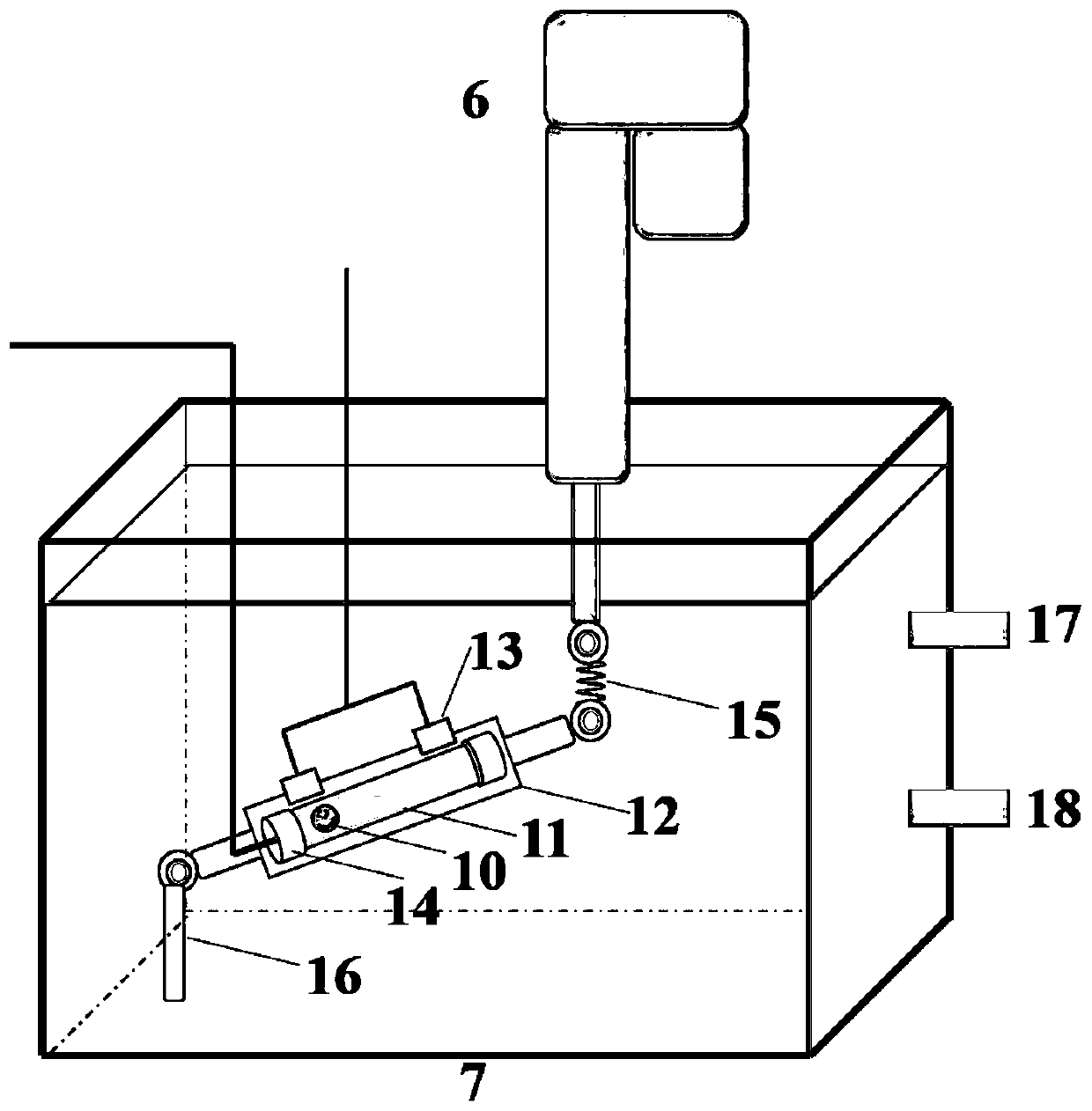

[0044] Such as Figure 1-Figure 2 As shown, the visual simulation device for hydrate formation, decomposition and clogging mechanism of this embodiment includes a normal pressure visualization hydrate reaction system, an electric motor system, a low temperature and constant temperature control system, a temperature acquisition system, and a CCD imaging system 2; the normal pressure visualization The hydrate reaction system includes a visual quartz tube, a stainless steel ball, a sealing plug 14, a metal protection frame and a metal detector 13. The metal protection frame is used as a mounting frame. The temperature acquisition system uses a first temperature sensor 4 and a second temperature sensor 5. The temperature sensor 4 and the second temperature sensor 5 adopt thermocouples. The metal detector 13 is installed on the metal protective frame and located at both ends of the quartz tube; the temperature probe of the first temperature sensor 4 is embedded in the sealing plug 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com