AI Training database for COF Film defects and application of AI Training database

A database and defect technology, applied in special data processing applications, image data processing, electrical digital data processing, etc., can solve problems such as long TactTime of inspection sites, long manpower training cycle, Overkill or Underkill, etc., and achieve the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with accompanying drawing.

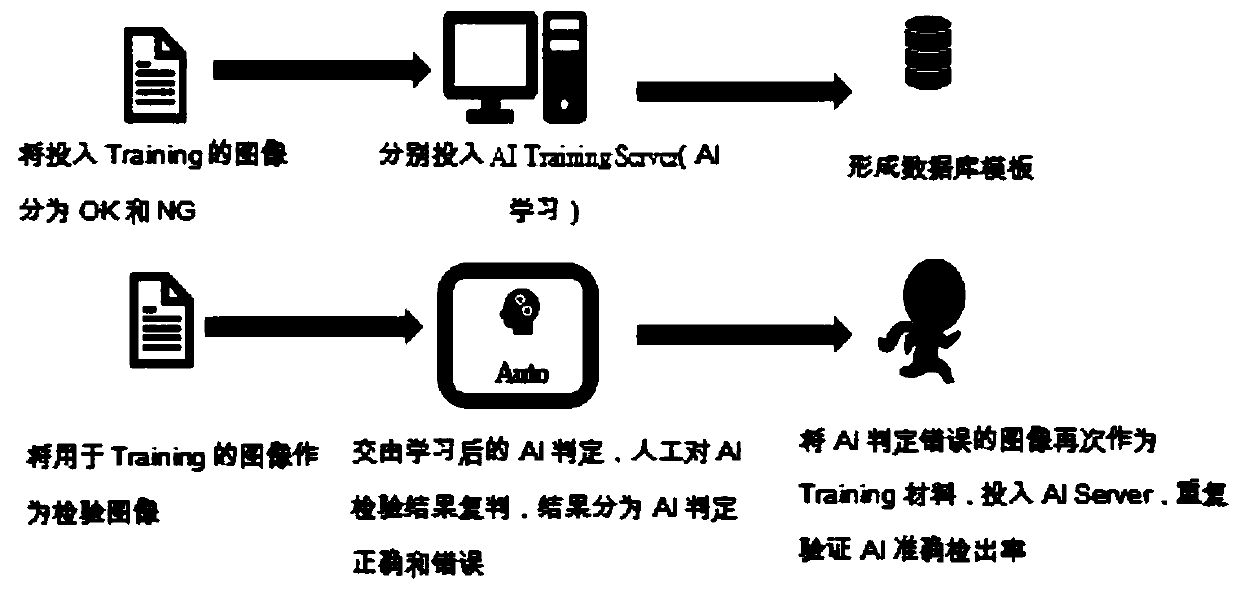

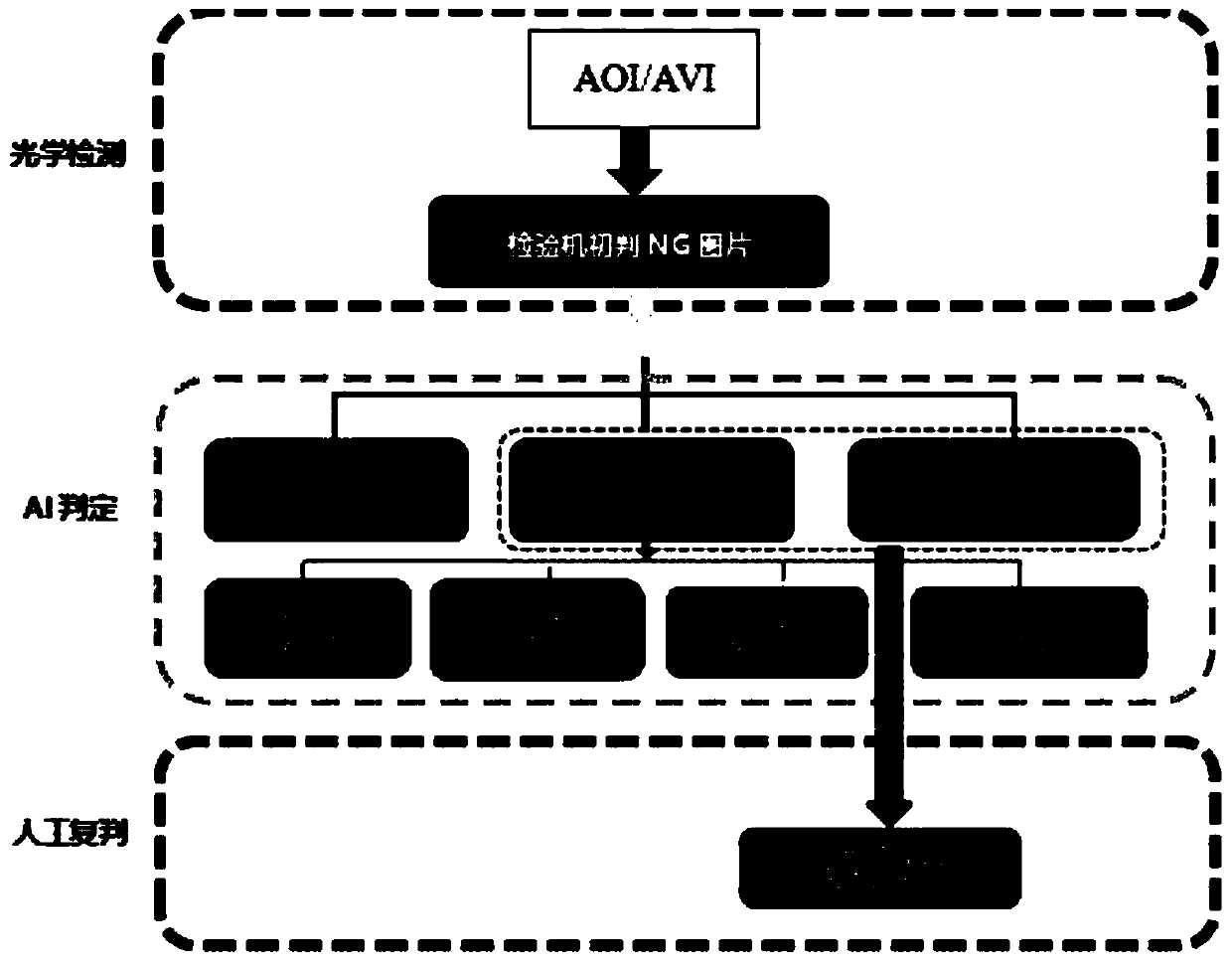

[0043] An AITraining database for artificial intelligence detection (AI, Automated Inspection) COF Film defects, such as figure 2 , the AI Training database is generated through the following steps:

[0044] S11. Manually distinguish and mark the image set as OK images and NG (not good) images; the images in the image set come from images taken by products that are suspected of being NG after the tin plating process is completed, or images taken after the process is completed. Products that are judged to be suspected of being NG by AVI detection are photographed and converted into images; the image set is divided into OK images and NG (not good) images manually by experienced inspectors.

[0045] S12, read the OK image and the NG (not good) image separated in S1 into an intelligent learning server (AITraining Server), and the intelligent learning server performs learnin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap