An app and two-dimensional code-based power equipment management system and its operating method

A technology of management system and operation method, which is applied in the field of power equipment management system based on APP and QR code, can solve the problems of time-consuming, low efficiency, safety production accidents and other problems of manual filling records, so as to improve the authenticity of work and improve the efficiency of work. The effect of improving efficiency and improving work level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

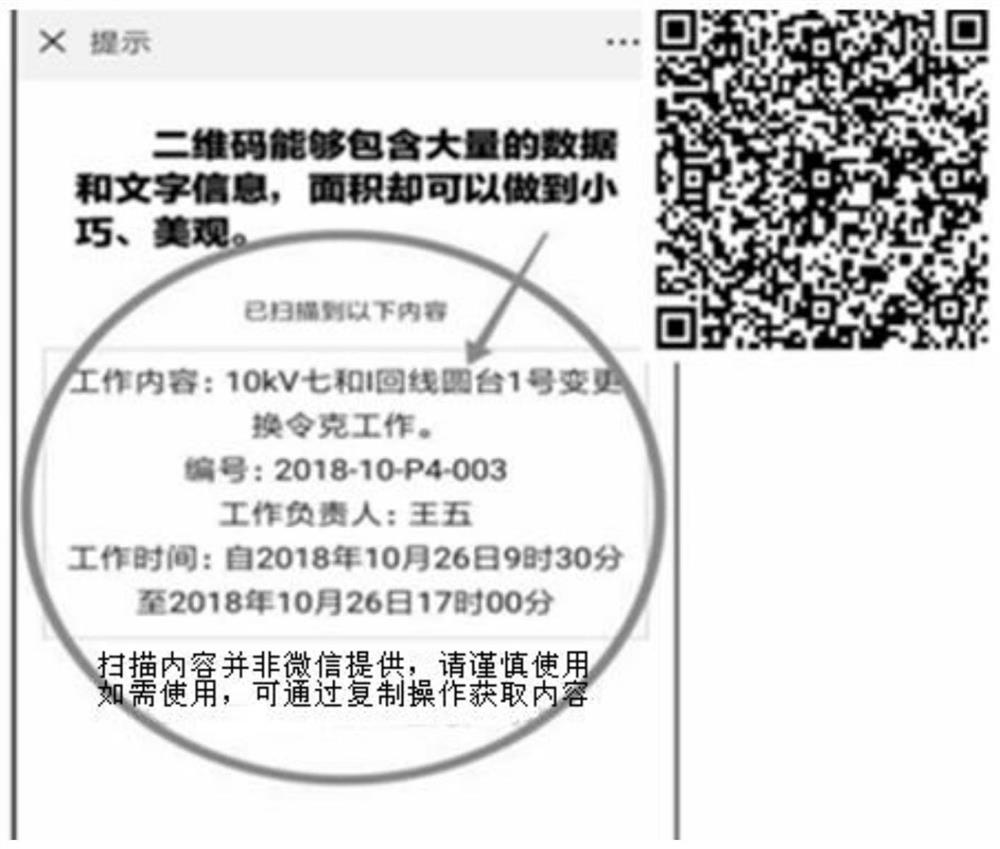

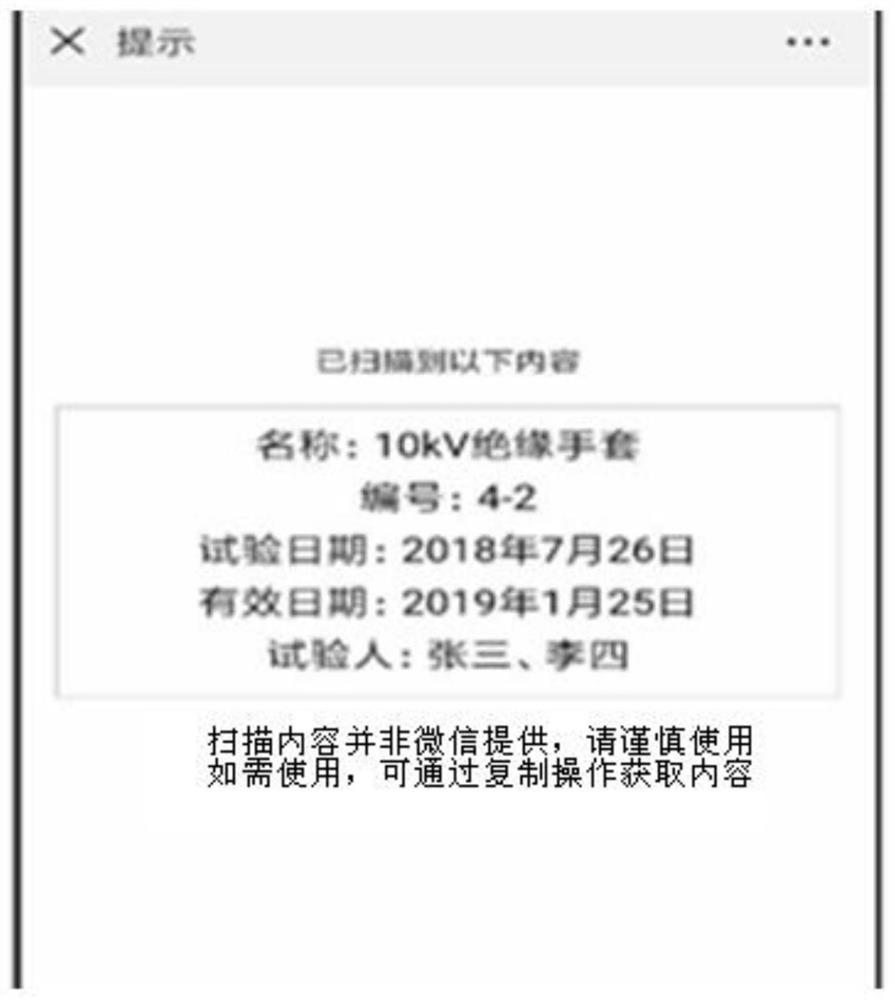

[0018] Embodiment 1: as Figure 1-Figure 2 As shown, a power equipment management system based on APP and QR code, including tool QR code, task QR code, receiving module, return module and positioning module, the information in the tool QR code includes tool name, No., test date, inspection time, and name of the tester. The information in the task QR code includes work tasks, ticket numbers, working hours and the person in charge. The receiving module scans the tool QR code and the task QR code to generate the corresponding work The work order task of the appliance receiving record and delivery, and print out the work order task, the return module generates the return record of the return tool and the completion of the work order task by scanning the QR code of the tool appliance, and the positioning module opens the mobile phone APP through the scanning terminal to scan After scanning the QR code, the receiving module and the returning module are activated by scanning the ter...

Embodiment 2

[0019] Embodiment 2: An operation method of a power equipment management system based on APP and two-dimensional code, the method is: the operator opens the mobile phone APP of the management system platform through the scanning terminal, after successful login, arrives at the warehouse, and the positioning module scans the terminal Automatic positioning with the location of the warehouse, if the same, the positioning is successful, activate the receiving module, scan the QR code of the tool through the receiving module, after the tool is picked up, the task work order and task QR code are automatically generated, and the work order and task are printed The QR code is dispatched to the operator. The operator scans the task QR code through the mobile APP to generate a task. After the operator completes the operation, he returns the tools and equipment, and the positioning module automatically locates the position of the scanning terminal and the warehouse. If they are the same, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com