Seawater coral aggregate concrete block with built-in frp reinforcement skeleton and its construction method

A technology for concrete blocks and tendon skeletons, applied in building materials, structural elements, building components, etc., can solve the problems of insufficient durability of concrete blocks, easy corrosion of steel bars, scarcity of resources, etc. Good performance, reducing the effect of tensile and compressive damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

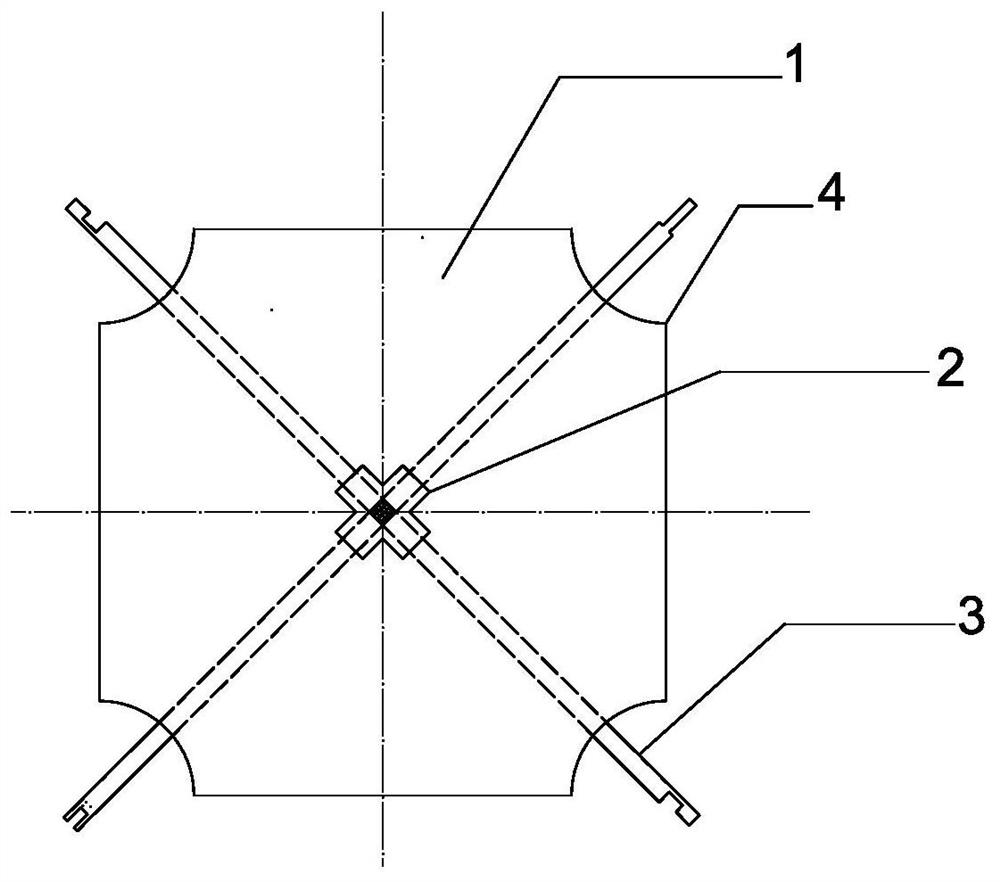

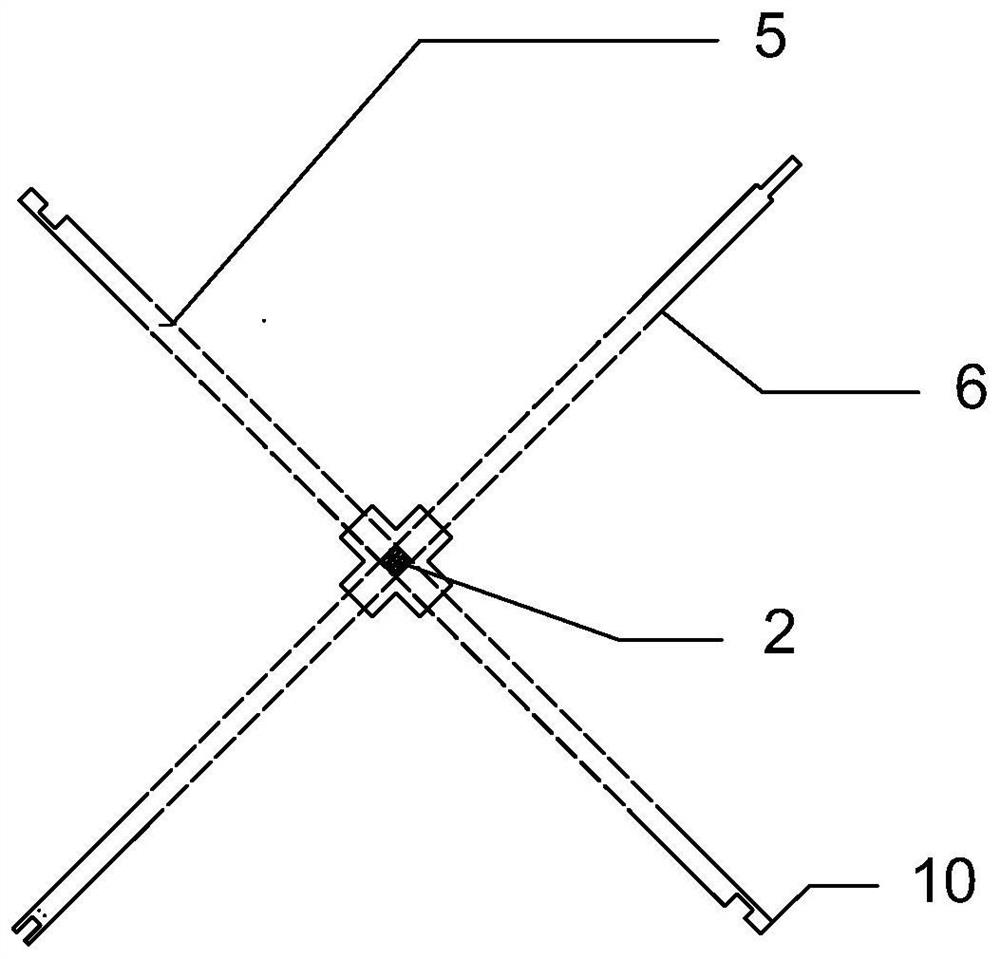

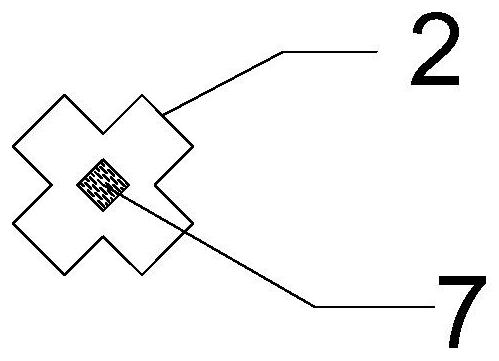

[0026] The present invention is a seawater coral aggregate concrete block with a built-in FRP tendon skeleton interlocking protection, comprising a coral aggregate seawater concrete block body 1, and an FRP tendon skeleton arranged on a layer of 1 / 2 thickness of the coral aggregate seawater concrete block body 1 3. The coral aggregate seawater concrete block body 1 is square, and the four corners of the square form arc edges 4 for splicing reserved channels. The FRP tendon skeleton 3 is composed of cross-shaped FRP sleeves 2, A long FRP tendon 5 passing through the FRP casing 2 is combined with two short FRP tendons 6 set on the FRP casing 2 at right angles to the long FRP The total length after 2 is equal to the length of a long FRP tendon 5, the direction of the long FRP tendon 5 and the short FRP tendon 6 is arranged along the diagonal direction of the facade of the whole coral aggregate seawater concrete block body 1, and the exposed end is located at the pre-splicing In t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com