Novel hotel floor towel production process

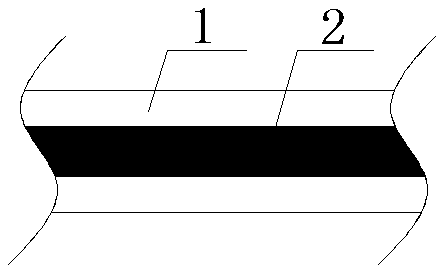

A production process and floor towel technology, applied in carpets, textiles, fabrics, etc., can solve the problems of poor hotel guests experience, reduced service life of floor towels, and easily damaged ear folds. The effect of release, improved wear resistance and tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

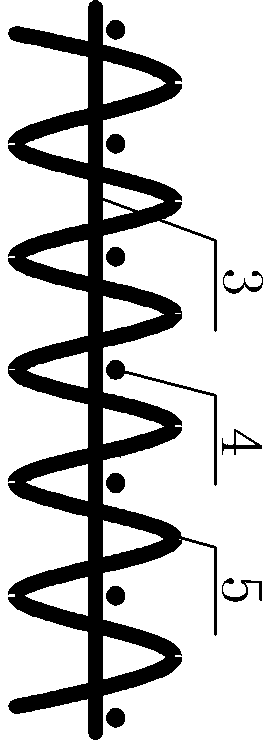

[0034] Embodiment 1: Conventional production process: the first step: yarn tube warping: the ear part of the ground towel all adopts ordinary cotton yarn tubes, and warps the full-width warp yarns;

[0035] The second step: sizing warp threading: combine the whole warp yarn into one piece, make it pass through the slurry, then press, dry, and wind into a weaving shaft, and then pass the warp yarn on the weaving shaft through the warp piece according to certain rules, healds and reeds;

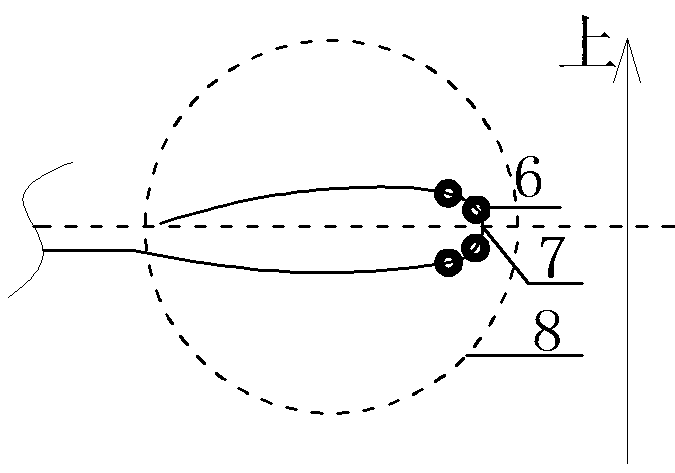

[0036] The third step: Weaving: interweave the processed warp and weft yarns into fabrics through the loom;

[0037] The fourth step: gray cloth bleaching: put the fabric into the dye vat for scouring, the temperature is 96°C, the scouring time is: 20min, then drain the hot water in the dye vat, and pour cold water into the dye vat for water cooling;

[0038] Step 5: Gray cloth rinsing: After the water cooling is over, first drain the water in the dyeing vat, then rinse the vat with cold water...

Embodiment 2

[0041] Embodiment 2: production process of the present invention: the first step: bobbin warping: select yarn location, determine the ear side position of the ground towel to be produced soon, and select 4 strands of warp yarns at the bending place of the ear side, and place 4 warp yarns at the bending place The ordinary cotton bobbins corresponding to the warp yarns are replaced with specially spun hot-melt adhesive warp bobbins, and the rest are still made of ordinary cotton bobbins, and the full-width warp yarns are warped;

[0042] The second step: sizing warp threading: combine the whole warp yarn into one piece, make it pass through the slurry, then press, dry, and wind into a weaving shaft, and then pass the warp yarn on the weaving shaft through the warp piece according to certain rules, healds and reeds;

[0043] The third step: Weaving: interweave the processed warp and weft yarns into fabrics through the loom;

[0044] Step 4: Gray fabric bleaching: put the fabric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com