Building backfill adhesive and preparation method thereof

A technology for bonding adhesives and construction, applied in the direction of adhesives, epoxy resin adhesives, adhesive types, etc., can solve the problems of large amount of adhesives and increased production costs, so as to improve waterproof and anti-seepage, reduce construction costs, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation method of building backfill adhesive:

[0043] Specifically include the following steps:

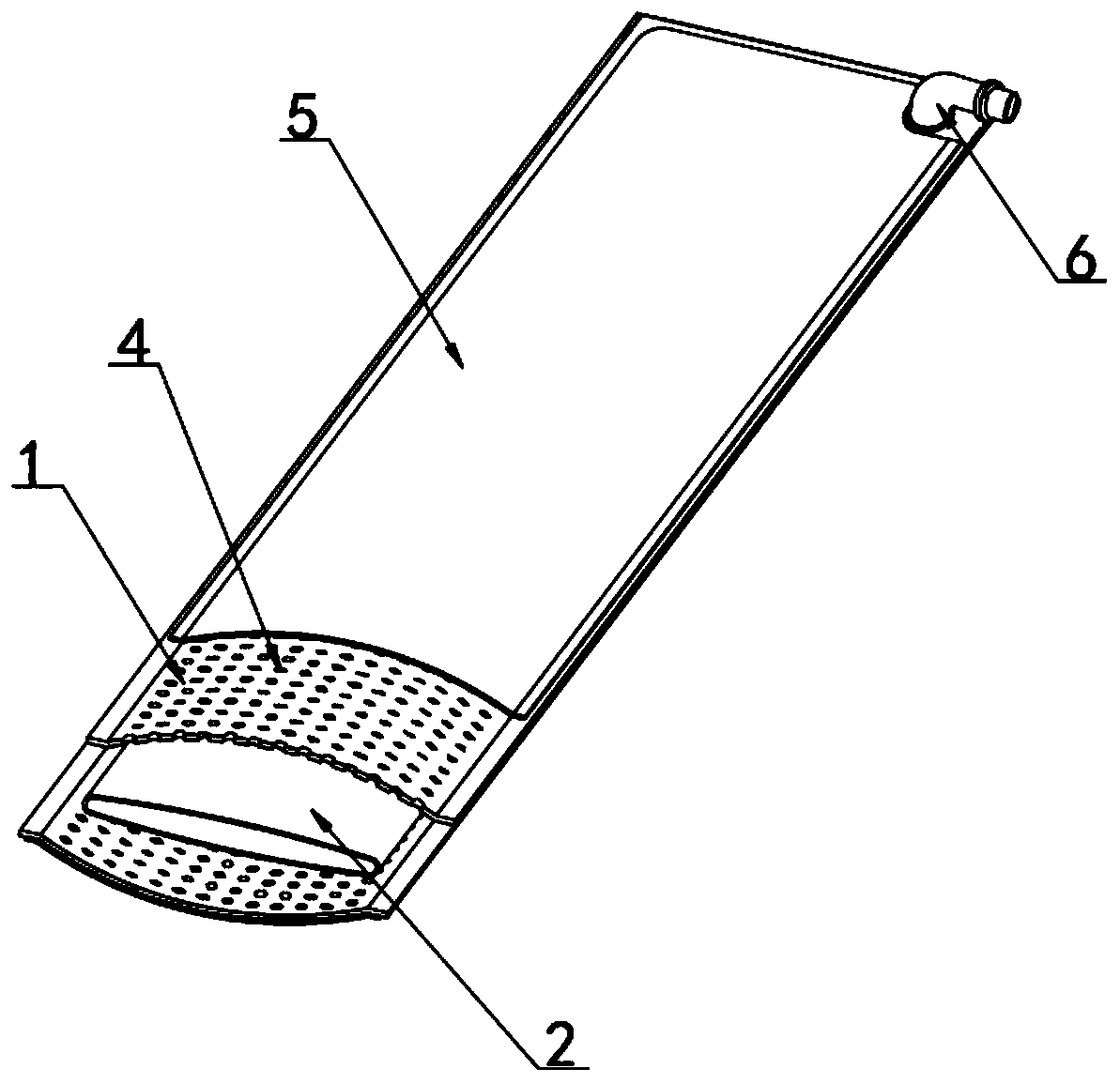

[0044] Step 1: Take the plastic paper and cut it into the required shape, use a heat sealing machine to make a pocket shape, reserve a pocket opening, use a stamping device to press out the glue hole 4 on the pocket, and then paste the sealing film 5 on both sides of the pocket surface, The sealing film 5 seals the glue outlet hole 4, and prepares the adhesive plastic bag body 1 for standby;

[0045] Step 2: Select the expansion extrusion bag body 2 that matches the shape of the adhesive plastic bag body 1 prepared in step one, remove the air inside the expansion extrusion bag body 2, and remove the expansion extrusion bag body 2 from the adhesive plastic bag body Insert the reserved bag opening on the body 1, install and fix the air pipe 6 to form a combination;

[0046] Step 3: The raw materials for preparing adhesive paste 3 are 50 parts of epoxy resin, 24 parts...

Embodiment 2

[0049] A preparation method of building backfill adhesive:

[0050] Specifically include the following steps:

[0051] Step 1: Take the plastic paper and cut it into the required shape, use a heat sealing machine to make a pocket shape, reserve a pocket opening, use a stamping device to press out the glue hole 4 on the pocket, and then paste the sealing film 5 on both sides of the pocket surface, The sealing film 5 seals the glue outlet hole 4, and prepares the adhesive plastic bag body 1 for standby;

[0052] Step 2: Select the expansion extrusion bag body 2 that matches the shape of the adhesive plastic bag body 1 prepared in step one, remove the air inside the expansion extrusion bag body 2, and remove the expansion extrusion bag body 2 from the adhesive plastic bag body Insert the reserved bag opening on the body 1, install and fix the air pipe 6 to form a combination;

[0053] Step 3: The raw materials for preparing adhesive paste 3 are 62 parts of epoxy resin, 27 parts...

Embodiment 3

[0056] A preparation method of building backfill adhesive:

[0057] Specifically include the following steps:

[0058] Step 1: Take the plastic paper and cut it into the required shape, use a heat sealing machine to make a pocket shape, reserve a pocket opening, use a stamping device to press out the glue hole 4 on the pocket, and then paste the sealing film 5 on both sides of the pocket surface, The sealing film 5 seals the glue outlet hole 4, and prepares the adhesive plastic bag body 1 for standby;

[0059] Step 2: Select the expansion extrusion bag body 2 that matches the shape of the adhesive plastic bag body 1 prepared in step one, remove the air inside the expansion extrusion bag body 2, and remove the expansion extrusion bag body 2 from the adhesive plastic bag body Insert the reserved bag opening on the body 1, install and fix the air pipe 6 to form a combination;

[0060] Step 3: The raw materials for preparing adhesive paste 3 are epoxy resin 74, ethylene glycol d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com