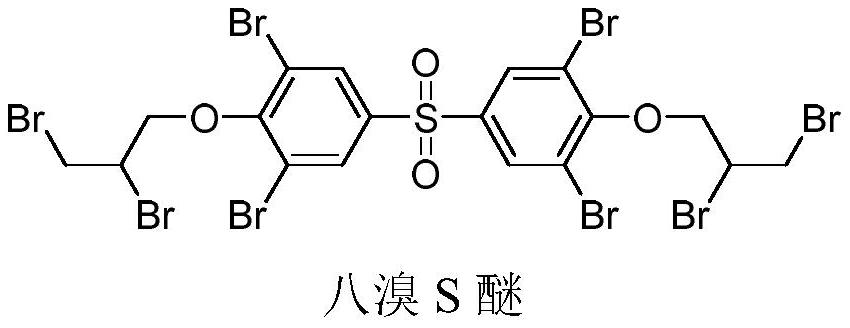

A kind of preparation method of octabromo S ether flame retardant

A technology of flame retardant and liquid bromine, which is applied in the field of preparation of octabromosulfide flame retardant, can solve the problems of low purity of octabromosulfide, long reaction route, high production cost, etc., achieve high yield and purity, and produce The effect of low cost and reduced production of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of preparation method of bisphenol S diallyl ether intermediate comprises steps as follows:

[0037] Add 200g of methanol, 50g of bisphenol S, 5g of sodium iodide, and 50g of water into a four-necked flask with stirring, and add 21g of sodium hydroxide under stirring. When the temperature of the solution reaches 35°C, start to add 45.5g of chloropropene dropwise under stirring. , the temperature of the system during the addition of allyl chloride is not higher than 60°C. After the addition of allyl chloride, the temperature is raised to 65°C, and the temperature is kept for 5 hours. The pH of the system is kept between 8 and 11 during the whole heat preservation reaction. At 8:00, solid sodium hydroxide was added to keep the pH of the system between 8 and 11. After the reaction, cool the reaction liquid to 15°C, filter it with suction, wash the solid obtained by suction filtration three times with water, and then dry the obtained solid at 75°C for 5 hours to obta...

Embodiment 2

[0040] A kind of preparation method of bisphenol S diallyl ether intermediate comprises steps as follows:

[0041] Add 220g of the mother liquor recovered in Example 1, 50g of bisphenol S, 5g of potassium iodide, and 30g of methanol into a four-neck flask with stirring, add 21g of sodium hydroxide under stirring, and when the temperature of the solution rises to 35°C, add 45.5g of it dropwise under stirring Allyl chloride, the temperature of the system during the addition of allyl chloride is not higher than 60°C. After the addition of allyl chloride, the temperature is raised to 65°C, and the reaction is kept for 5 hours. The pH of the system is kept between 8 and 11 during the whole heat preservation reaction process. When it is lower than 8, add solid sodium hydroxide to keep the pH of the system between 8 and 11. After the reaction, the resulting reaction solution was cooled to 15°C, filtered with suction, and the solid obtained by suction filtration was washed with water ...

Embodiment 3

[0046] A kind of preparation method of bisphenol S diallyl ether intermediate comprises steps as follows:

[0047] Add 200g of n-propanol, 50g of bisphenol S, 5g of sodium bromide, and 50g of water into a four-necked flask with stirring, and add 21g of sodium hydroxide under stirring. When the temperature of the solution reaches 35°C, add 45.5g of it dropwise under stirring Allyl chloride, the temperature of the system during the addition of allyl chloride is not higher than 60°C. After the addition of allyl chloride, the temperature is raised to 65°C, and the reaction is kept for 5 hours. The pH of the system is kept between 8 and 11 during the whole heat preservation reaction process. When it is lower than 8, add 30% sodium hydroxide solution to keep the pH of the system between 8 and 11. After the reaction, cool the reaction liquid to 15°C, filter it with suction, wash the solid obtained by suction filtration three times with water, and then dry the solid at 75°C for 6 hours ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com