Technology and device for producing defluorinated phosphoric acid

A technology for defluorinated phosphoric acid and production equipment, applied in the fields of phosphorus compounds, inorganic chemistry, non-metallic elements, etc., can solve problems such as the entry of fluorine resources, and achieve the effect of increasing the fluorine escape rate and increasing the surface reaction area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

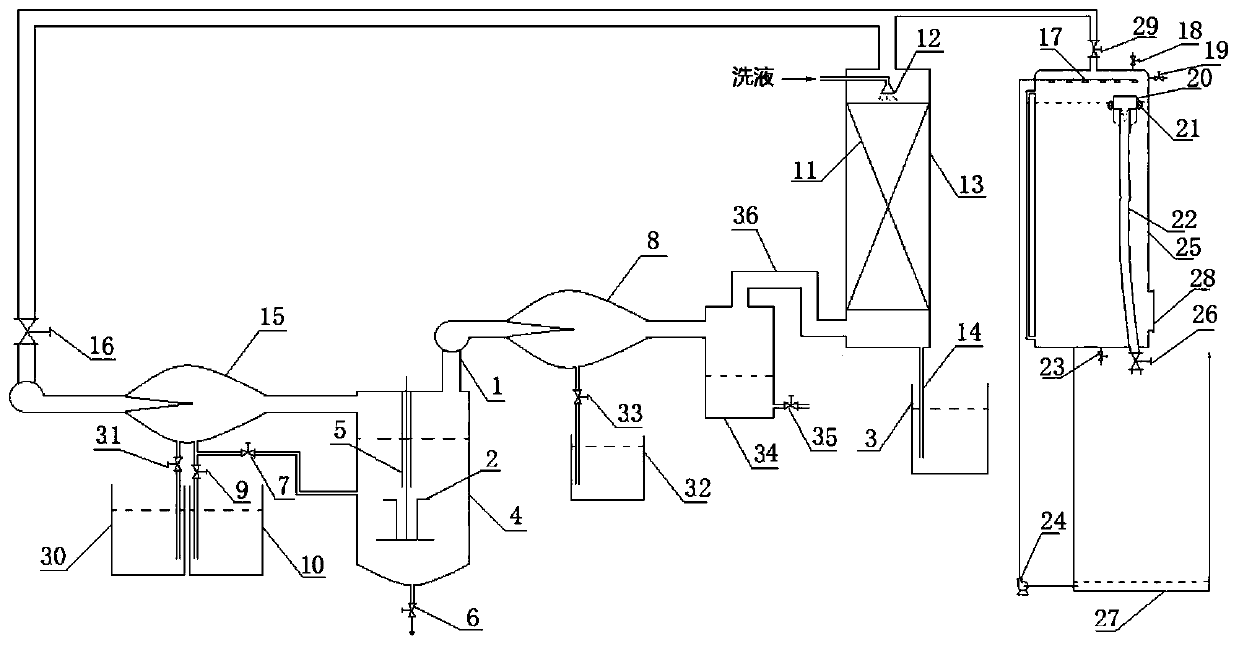

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0029] The invention includes the production process of defluorinated phosphoric acid, and its technical feature is that the fluorine-containing phosphoric acid produced by wet-process phosphoric acid is divided into two parts, one part is returned to the phosphoric acid production reaction kettle to react with phosphate rock slurry, which is called back acid, and the other part is used as a crude product , which is called crude phosphoric acid; the jet pump A, reactor, jet pump B, gas-liquid separator, and absorption tower are connected in turn by pipelines to form a loop closed pipeline system, and the system is controlled to be in a micro-negative pressure state; the jet pump A , B Let the gas in the system circulate at high speed, the vacuum generated by the jet pump first sucks the back acid and sulfuric acid into the vacuum chamber and mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com