Lifting stand column with small installation distance

A technology of lifting column and installation distance, which is applied in the direction of lifting device, etc., can solve the problems of large installation distance of lifting column, inconvenient transportation, high height, etc., and achieve the effect of reducing installation distance, compact axial and radial directions, and stable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

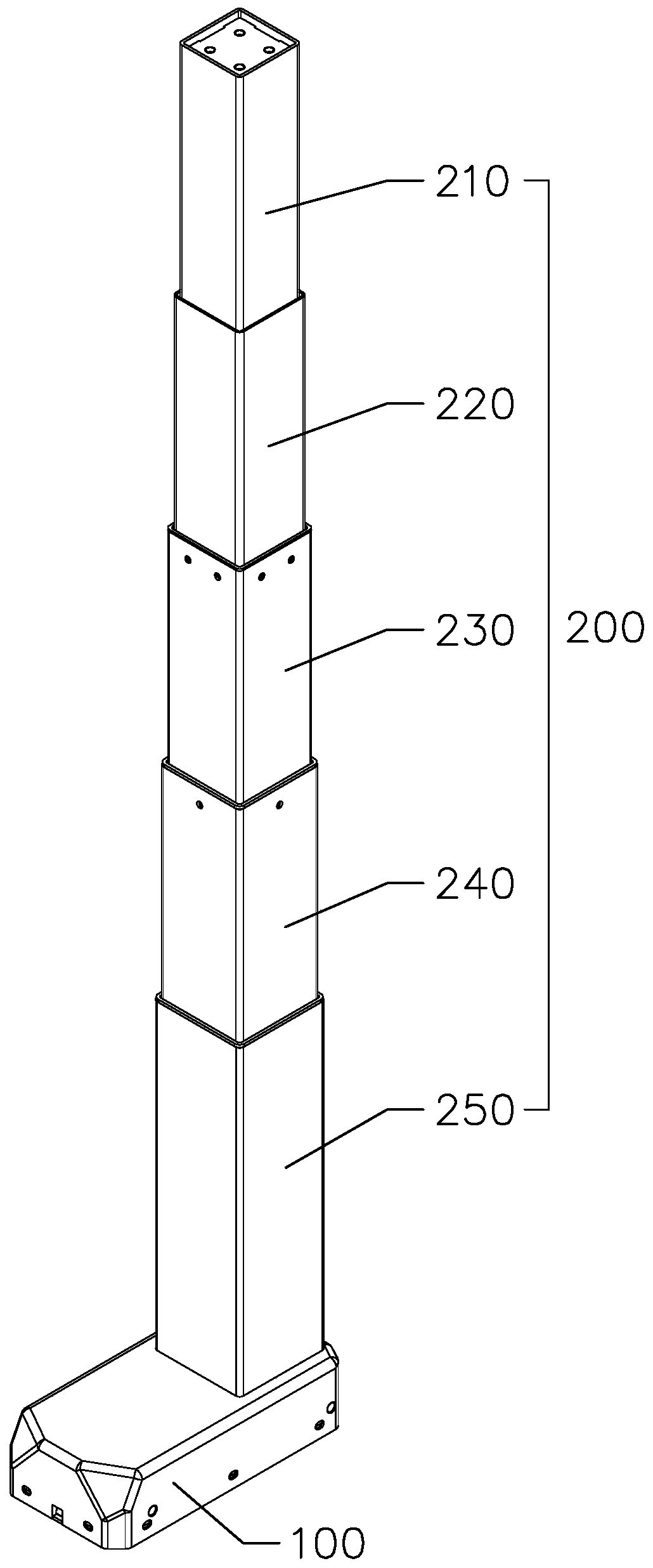

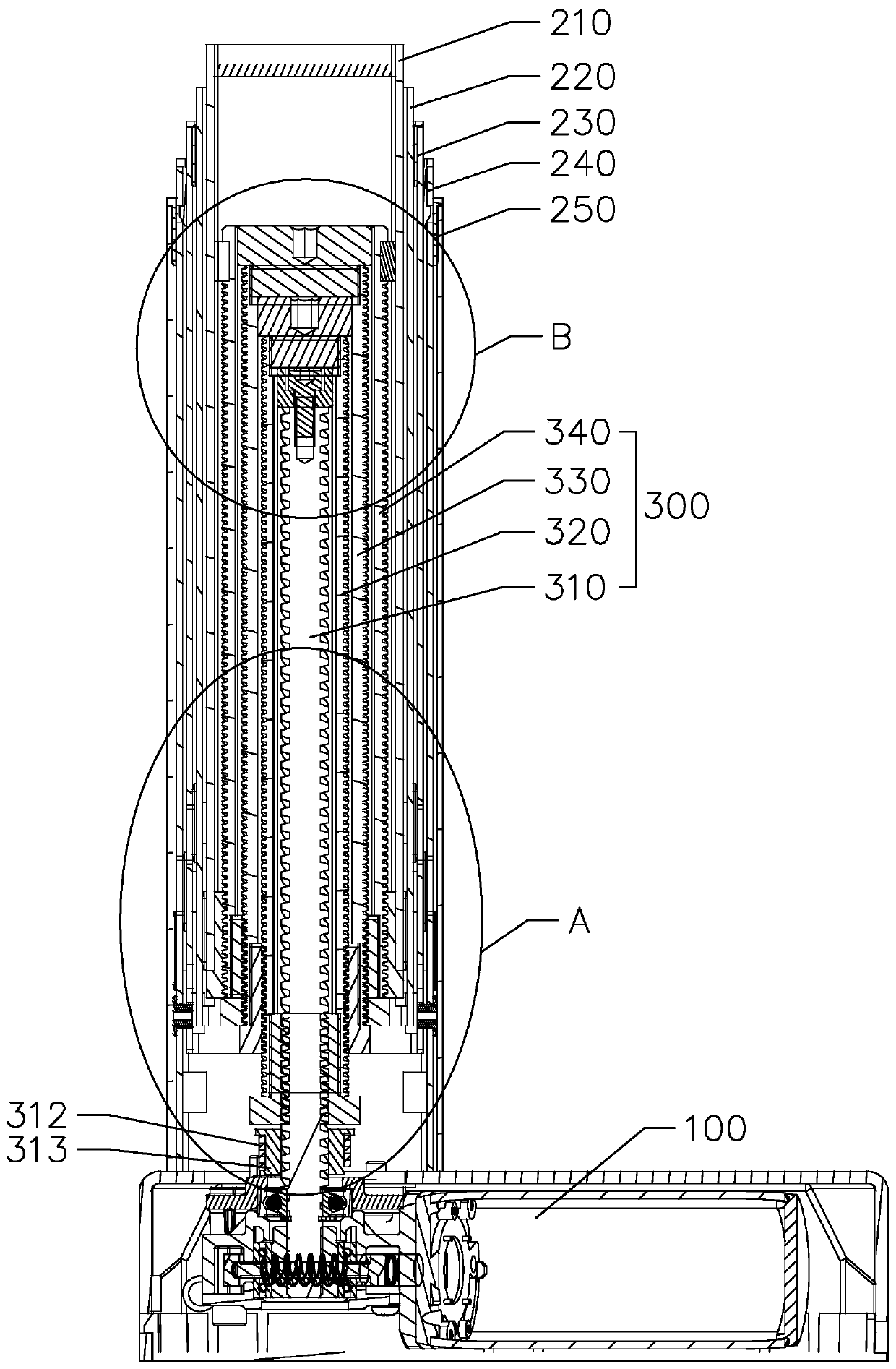

[0037] Such as Figure 1 to Figure 4 As shown, the present invention provides a lifting column with a low installation distance, including a driving device 100, a lifting tube 200 and a transmission assembly 300 inside the lifting tube 200. The lifting tube 200 includes a first tube 210, The second pipe 220, the third pipe 230, the fourth pipe 240 and the fifth pipe 250, by setting the lifting column into five sections, the installation distance of each section of the lifting pipe can be reduced, so that the installation distance is relatively low, and the fifth pipe 250 The lower end of the first pipe 210 is fixed on the driving device 100, the driving device is located at the lower end of the lifting column, the upper end of the first tube 210 is fixed on the lifting platform, the lifting column is in an upside-down state, and the transmission assembly 300 includes the first wires that are sequentially fitted from the inside to the outside. The rod 310, the second hollow scr...

Embodiment 2

[0048] The main difference between the present embodiment and the first embodiment is that the lifting column is in the normal installation state.

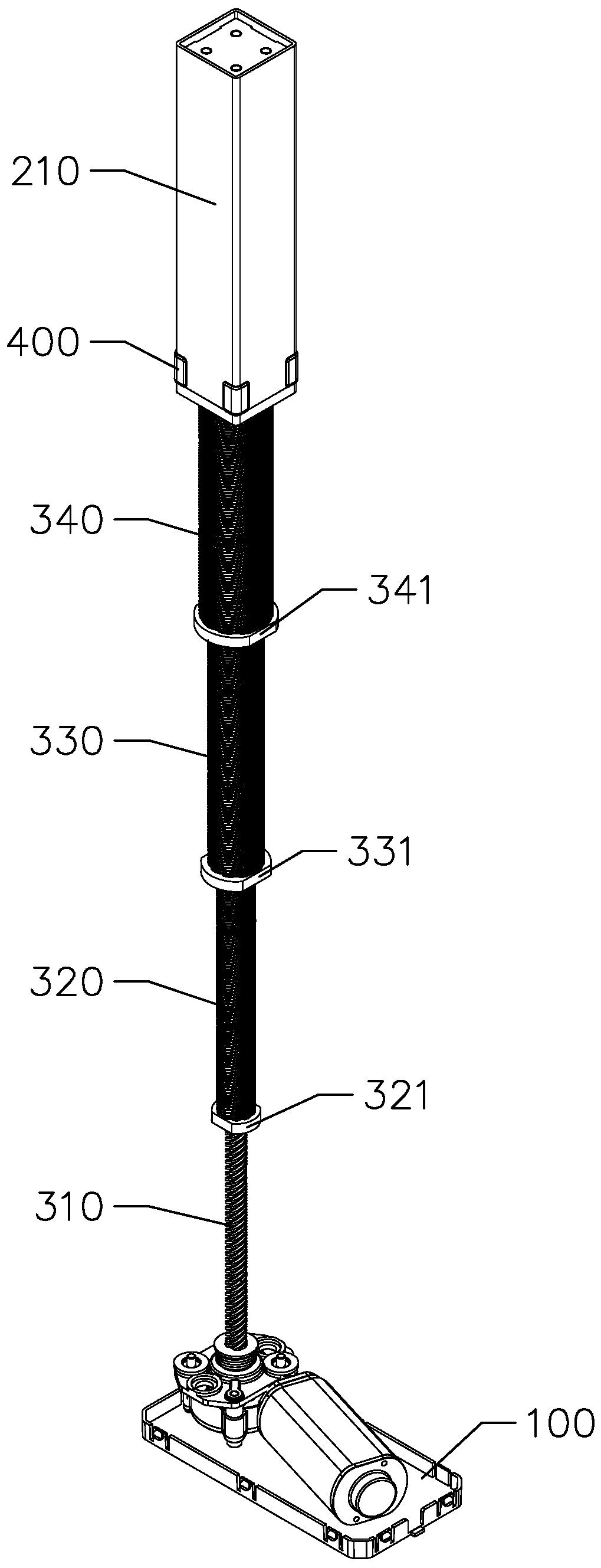

[0049] Such as Figure 7 and Figure 8 As shown, the lifting column is in the normal installation state, the driving device 100 is fixed on the lifting platform, the lifting tube 200 is located at the lower end of the driving device 100, the first nut 321 is located at the upper end of the second screw rod 320, and the second nut 331 is located at the third screw rod 320. On the upper end of the rod 330 , the third nut 341 is located on the upper end of the fourth screw rod 340 , and the fourth nut 221 is located on the upper end of the first tube 210 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com