Dual motor lifting stand column

A technology of lifting columns and dual motors, applied in the direction of lifting devices, controlling mechanical energy, electrical components, etc., can solve the problem of high installation distance, achieve the effect of small operating current, fast lifting, and avoid the effect of unable to lift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

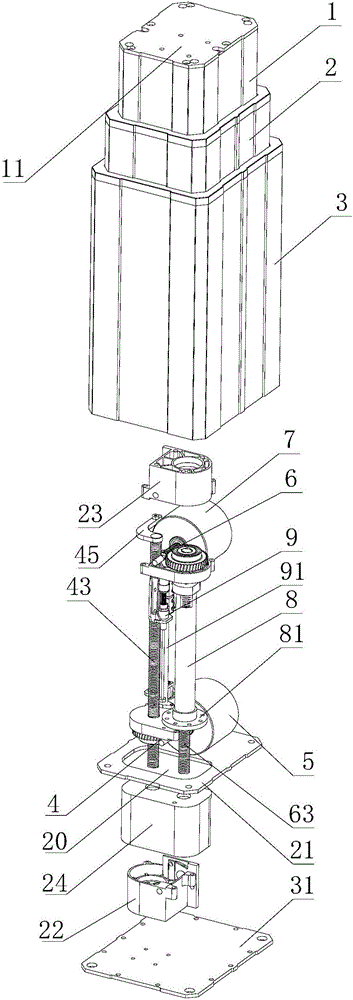

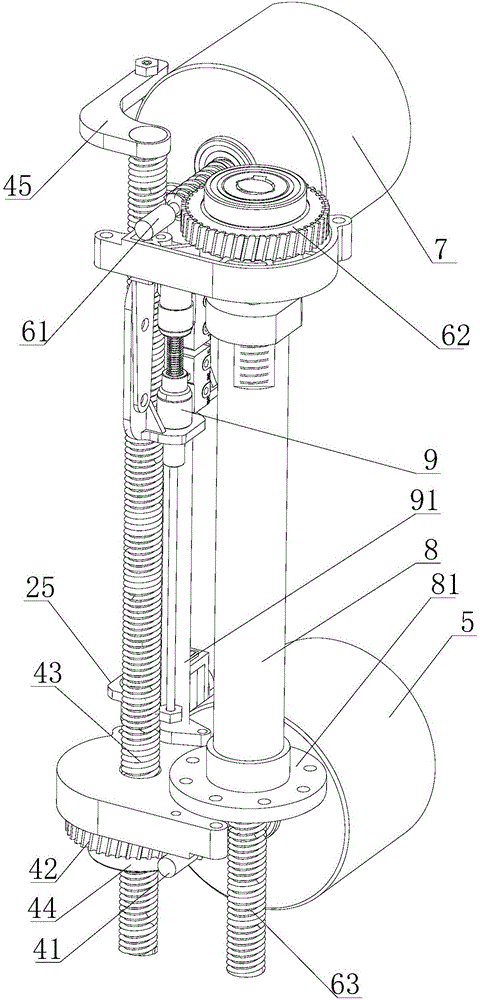

[0021] Such as figure 1 As shown, a double-motor lifting column includes an inner tube 1, a middle tube 2 and an outer tube 3. The inner tube 1 is inserted into the middle tube 2, and the middle tube 2 is inserted into the outer tube 3. It also includes an inner tube end plate 11, a middle tube Tube end plate 21, outer tube end plate 31, first gear box 22 and second gear box 23, the first gear box 22 is arranged on the middle tube end plate 21, and the first transmission system 4 is connected to the first gear box 22 , the output end of the first transmission system 4 is connected with the first gear box 22, the input end of the first transmission system 4 is connected with the first motor 5, the first motor 5 is fixedly connected on the middle tube end plate 21, the middle tube end plate 21 is arranged on the bottom end of the middle pipe 2, the second gear box 23 is provided with the second transmission system 6, the output end of the second transmission system 6 is connecte...

Embodiment 2

[0026] A double-motor elevating column as described in Embodiment 1, this embodiment has the following differences: the first transmission system and the second transmission system are arranged as a ball screw and nut transmission structure, and the nut is arranged on the ball screw, Both the middle tube and the inner tube are fixedly connected to the nut, and the ball screw is respectively connected to the first motor and the second motor through the reduction gear box, and the rotation of the ball screw is controlled by the motor, driving the nut to go up and down on the ball screw, respectively. Lifting of middle tube and inner tube.

[0027] During use, the first motor 5 drives the first worm screw 41 to rotate, drives the first worm wheel 42 and the first screw mandrel 43 to rotate, thereby realizing that the first gear box 22 does linear motion on the first screw mandrel 43, and the first gear box 22 Drive the middle tube end plate 21 to rise and fall synchronously, so a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com