Vacuum cooling box for pipe machining extrusion

A vacuum cooling and pipe technology, applied in the field of vacuum cooling boxes for pipe processing and extrusion, can solve the problems of product quality and production index loss, poor water quality in production workshops, disconnection, etc., to reduce quality fluctuations and missed inspection risks, The effect of reducing labor intensity and increasing water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

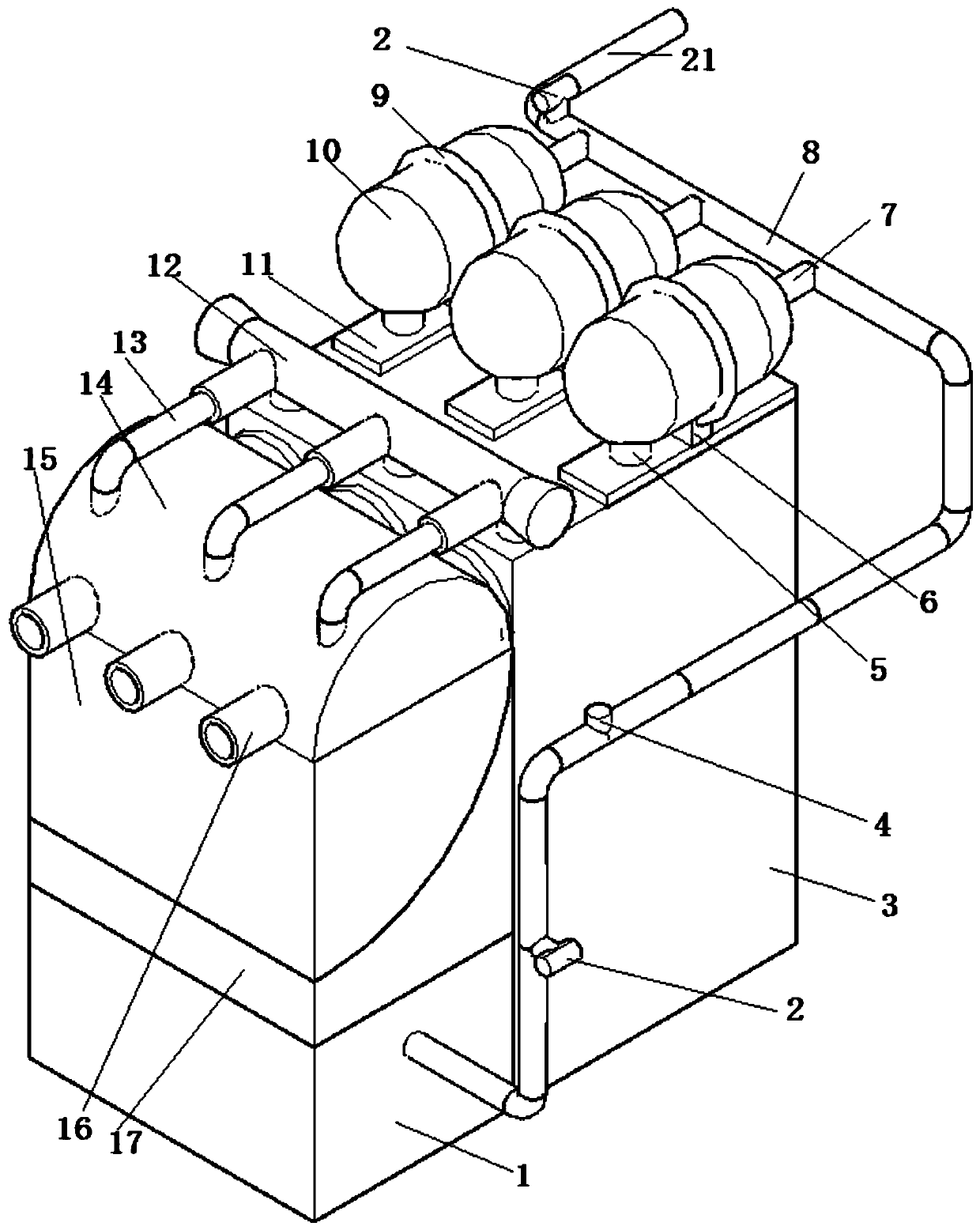

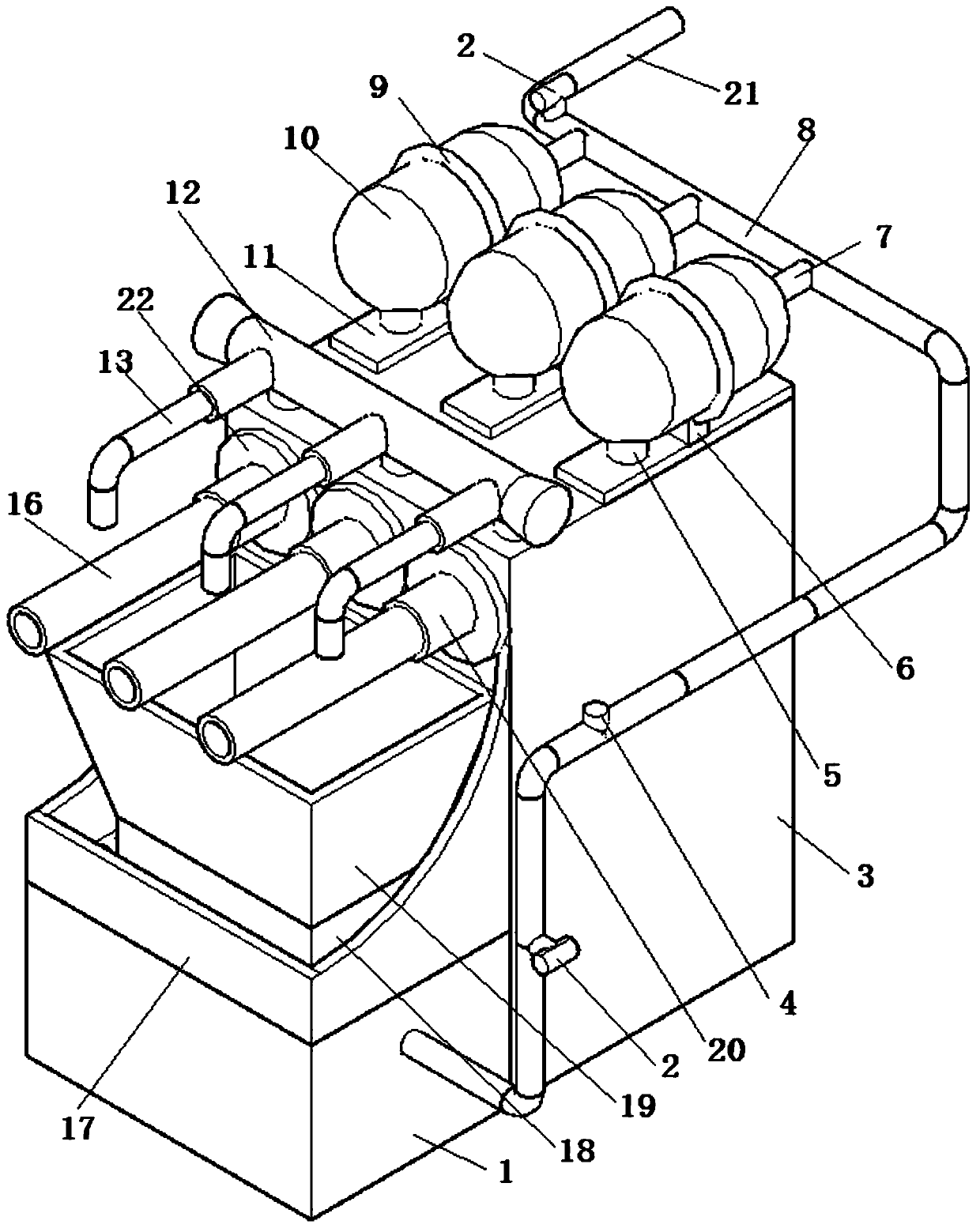

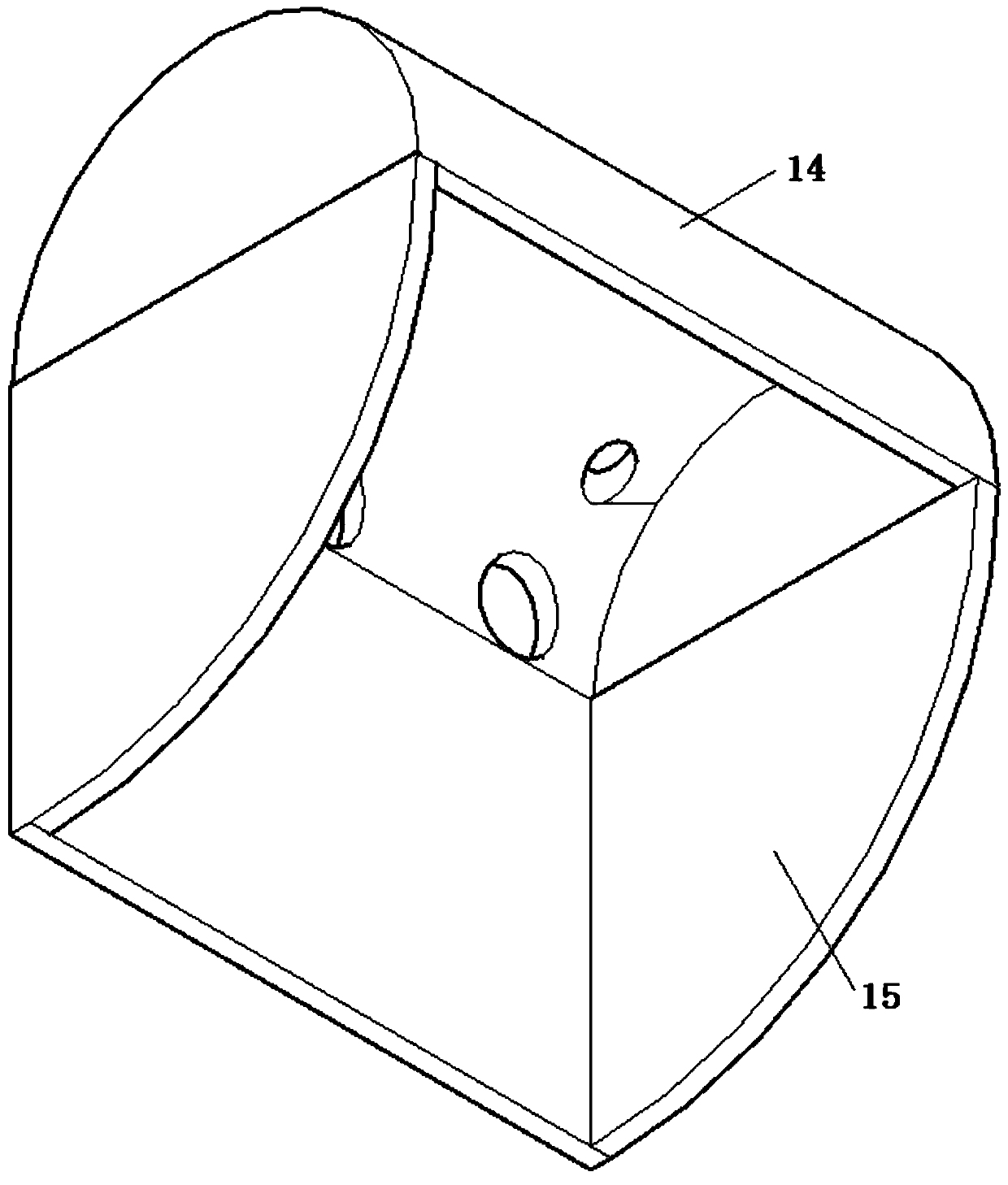

[0019] Such as Figures 1 to 4 As shown, this embodiment provides a vacuum cooling box for pipe processing and extrusion, including an extruder, and one side of the extruder is fixed with a water passing mechanism located above the water collection box and below the pipe outlet. The top of the water passing mechanism is fixed with a condensate cover, and the top of the extruder is fixed with a number of vacuum water tanks through the installation structure. The water collection tanks are connected, and the outlet pipe of the vacuum water tank is connected with several drainage pipes through the cooling water integration pipe, and the end of the water guide pipe is connected with a water supply pipe with a valve connected with the cooling water sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com