Multi-robot cooperation lockset panel manufacturing process

A multi-robot, manufacturing process technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problem of unstable clamping effect, and achieve the effect of shortening turnaround time, improving manufacturing efficiency, and improving fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

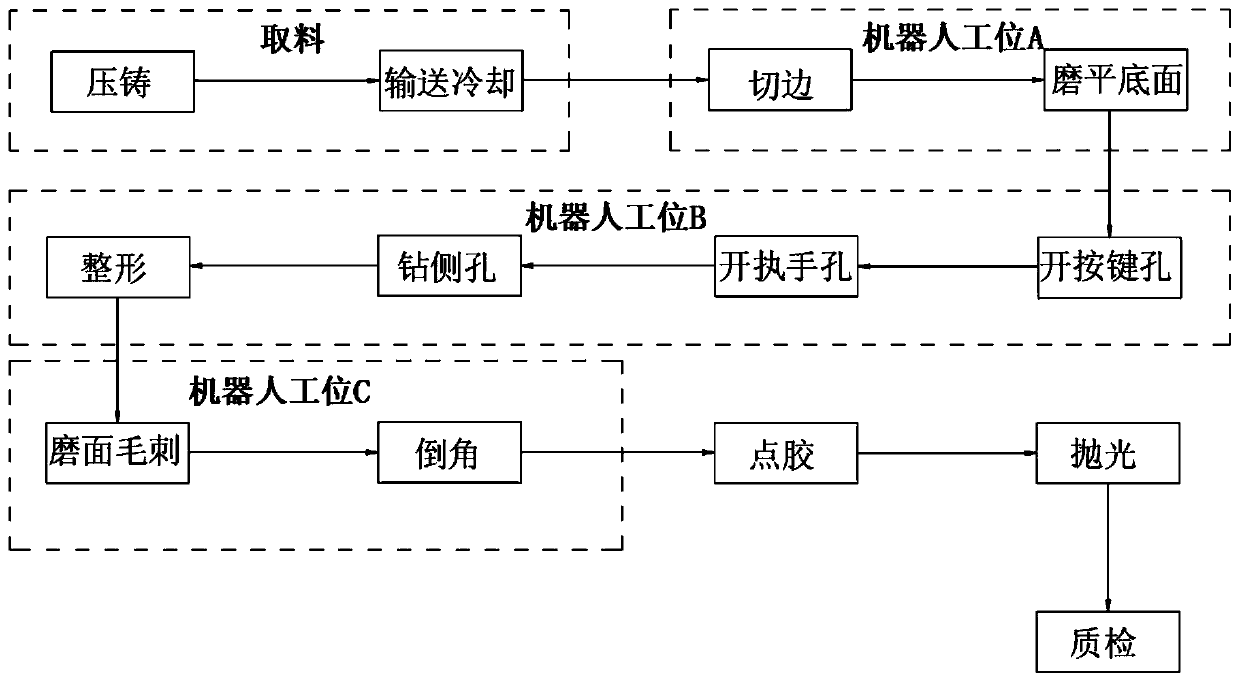

[0026] A multi-robot collaborative lock panel manufacturing process, such as figure 1 As shown, there are three groups of robot stations for control, including the following steps: Die-casting → Conveying and cooling → Trimming → Flat bottom surface → Opening button holes → Opening handle holes → Drilling side holes → Shaping → Grinding burrs → Chamfering → Dispensing→polishing→quality inspection, die-casting, conveying and cooling are the steps of material retrieving, edge trimming and flat bottom surface are controlled by robot station A in sequence, shaping, drilling side holes, opening handle holes, and key holes are sequentially controlled by robot station B For control, the grinding surface burr and chamfering process are sequentially controlled by the robot station C.

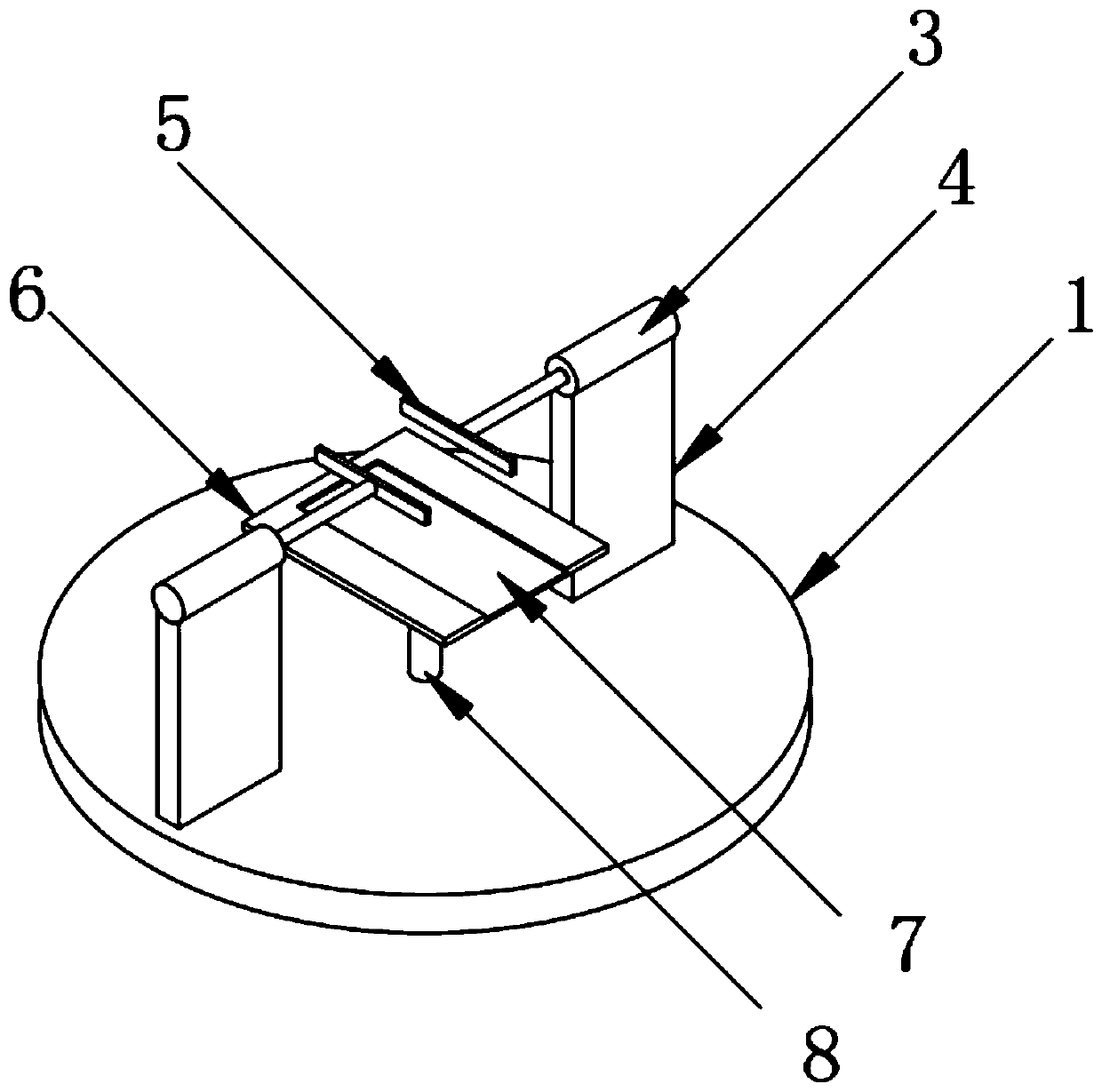

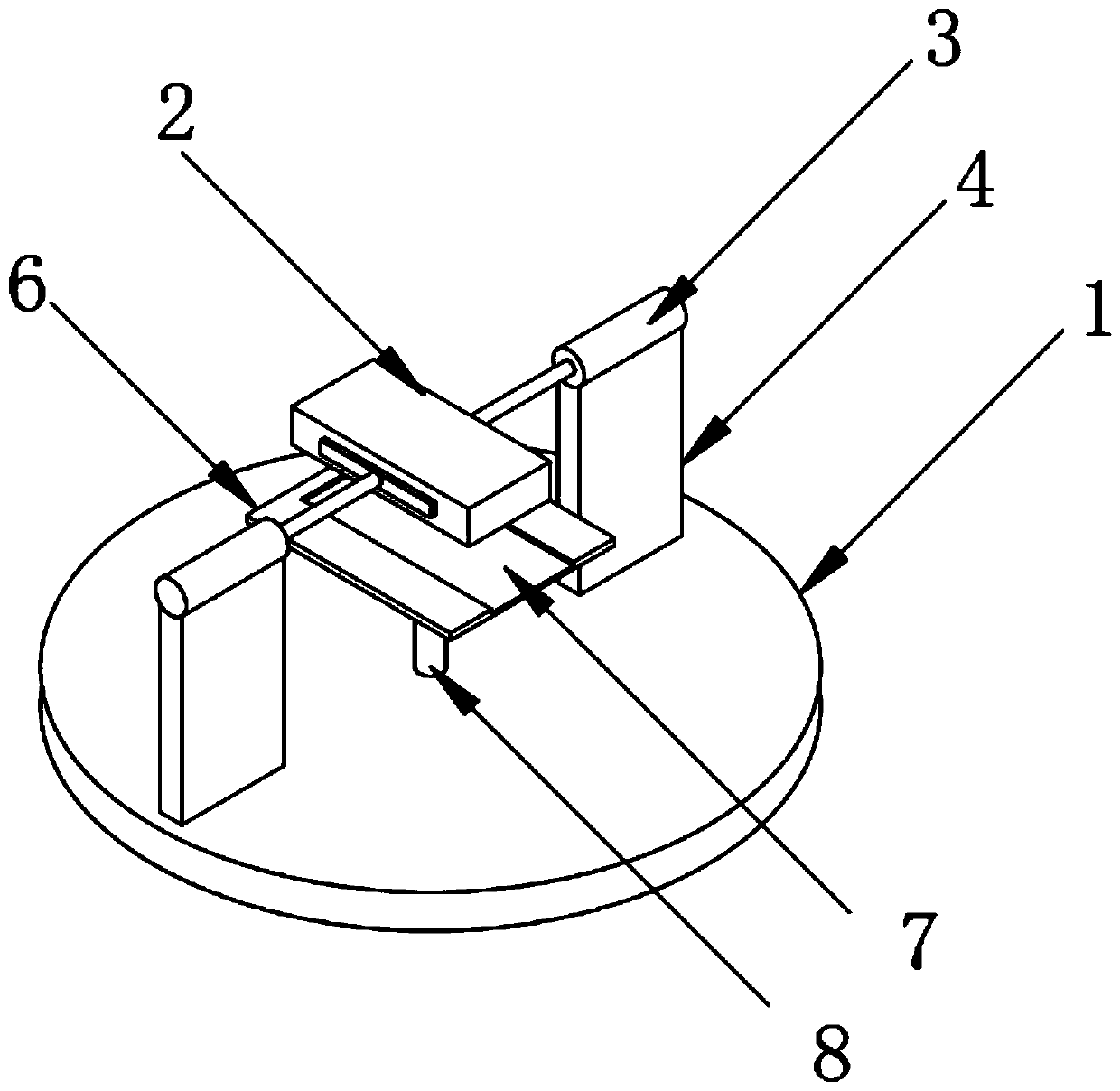

[0027] Further, the fixed high-speed spindle and the movement of the manipulator to clamp the wool fittings are used for edge trimming and flat bottom surface, and the T-shaped milling cutter is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com