Anti-abrasion sealing nut

A technology of sealing nuts and sealing rings, which is applied in the direction of nuts, bolts, threaded fasteners, etc., can solve the problems of poor sealing, single structure, and low service life, and achieve the goal of improving sealing performance, improving fixing effect, and improving wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

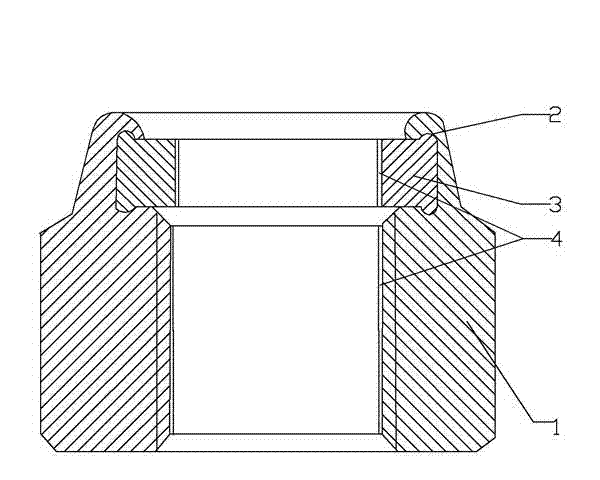

[0012] like figure 1 As shown, the wear-resistant sealing nut includes a body 1, a groove 2, a sealing ring 3 and a wear-resistant coating 4. The upper end of the body 1 is provided with a groove 2, the sealing ring 3 is arranged in the groove 2, and the inner ring of the sealing ring 3 And the inner wall of the main body 1 is coated with a wear-resistant coating 4, and the wear-resistant coating is made of titanium nitride-based intermetallic compound.

[0013] The groove 2 is a double-groove groove, and the thickness of the sealing ring 3 is greater than the depth of the groove 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com