Method for realizing optimal finishing amount of formed electrode loss based on point cloud data processing

A technology for forming electrodes and point cloud data, which is applied in electrode manufacturing, measuring devices, electric processing equipment, etc., to achieve the effects of increasing the utilization rate of forming electrodes, improving processing efficiency, and ensuring trimming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The isosceles trapezoidal cross-section forming electrode physical map and cross-sectional geometric dimensions used in this embodiment are as follows figure 2 As shown, specifically: a wedge-shaped structure, the width of the electrode, that is, the length of the wedge-shaped surface is 7mm, the wedge-shaped angle is 20°, and the thickness of the narrow side is 0.8mm.

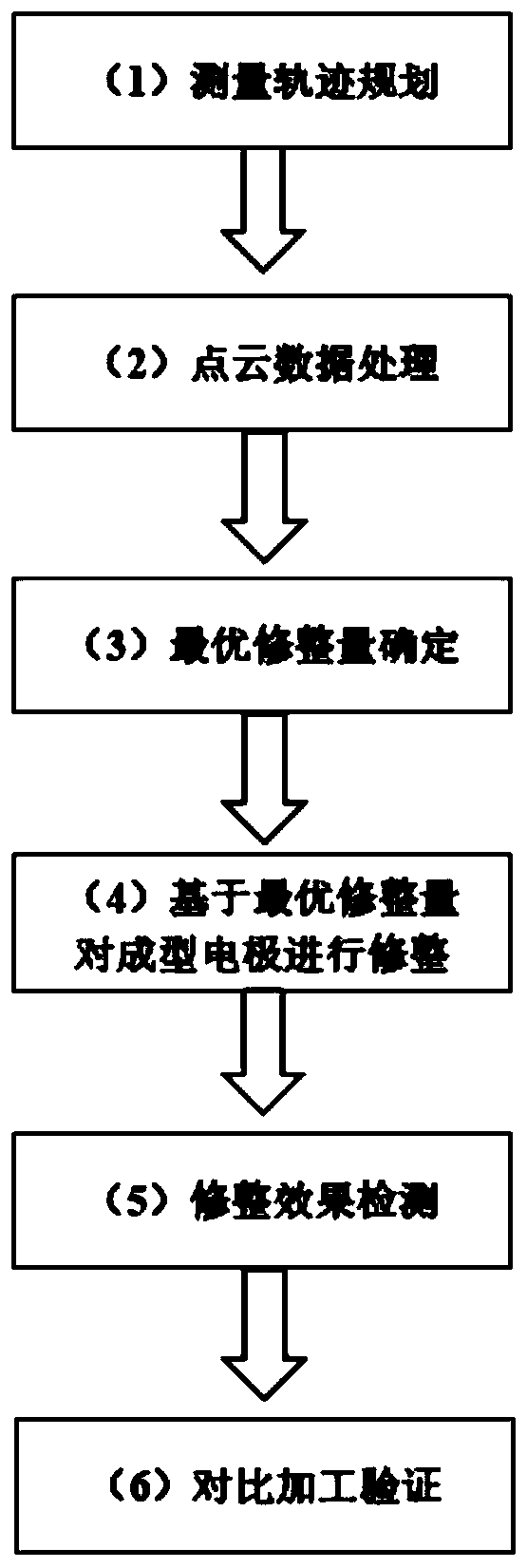

[0025] Such as figure 1 As shown, this embodiment involves a method for realizing the optimal trimming amount of forming electrode loss based on point cloud data processing, including the following steps:

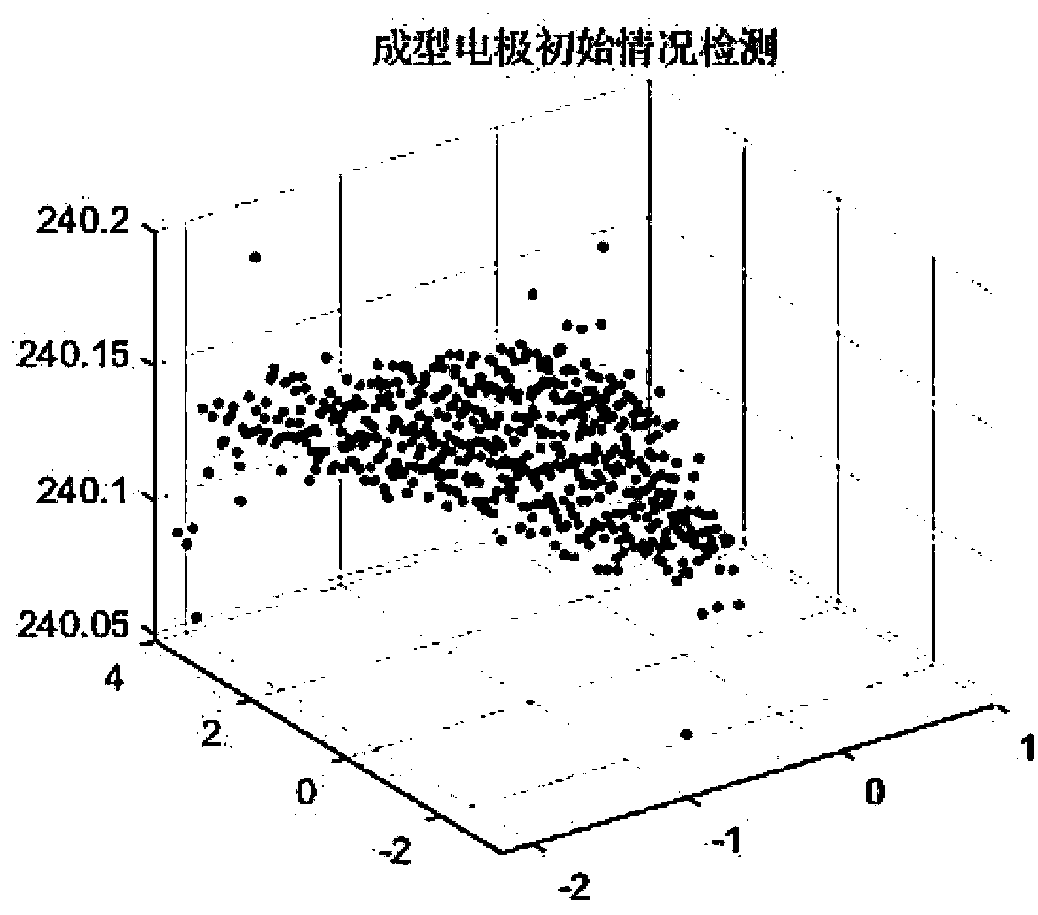

[0026] Step 1) Measurement trajectory planning: use a laser three-coordinate measuring machine to measure the loss of the forming electrode, determine the coordinate range of the plane to be measured in the workpiece coordinate system in advance, and combine the geometric space motion structure of the laser three-coordinate measuring machine to derive the to-be The coordinates of the measuring plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com