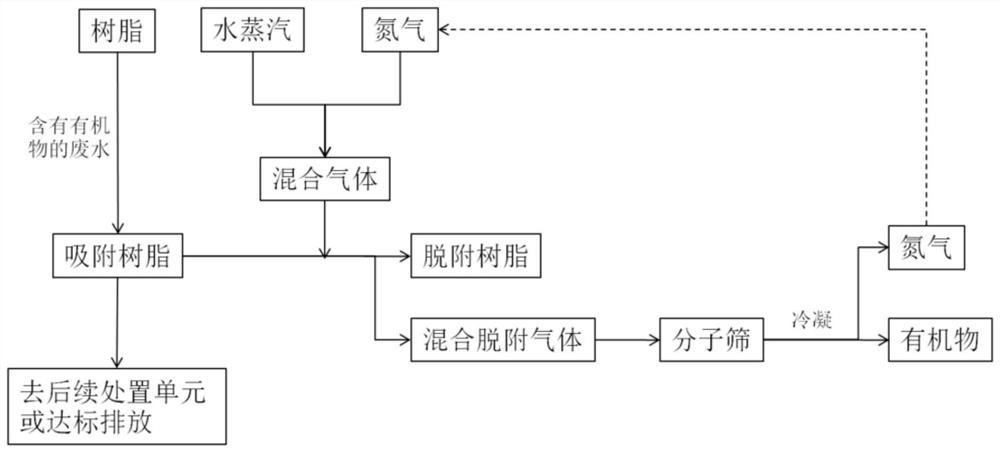

A resin desorption regeneration method for adsorbing organic matter

A technology of organic matter and resin, which is applied in the field of resin regeneration, can solve the problems of organic flow loss, large amount of waste water, difficult treatment, etc., and achieve the effects of easy control, reduction of waste water, and heat saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] q=N·Q

[0051] Q=a·q·T

[0052] t

[0054] In the present embodiment, the correlation coefficient a is 0.5, and the correction coefficient b is 0.005. It can be seen from the above that q=240kg,

Embodiment 2

[0070] q=N·Q

[0074] Q=a·q·T

[0075] t

[0077] In the present embodiment, the correlation coefficient a is 0.6, and the correction coefficient b is 0.003. As can be seen from the above, q=126kg,

[0080] 5) After desorption and regeneration, the calculated desorption rate of the method in the present embodiment is 99% according to the amount of the recovered organic matter.

Embodiment 3

[0088] q=N·Q

[0092] Q=a·q·T

[0093] t

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com