Preparation method of shell powder loaded antibacterial material

A technology of antibacterial materials and shell powder, which is applied in the field of preparation of shell powder loaded antibacterial materials, can solve problems such as research and lack of antibacterial materials, achieve the effects of avoiding environmental problems, outstanding antibacterial effects, and expanding application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

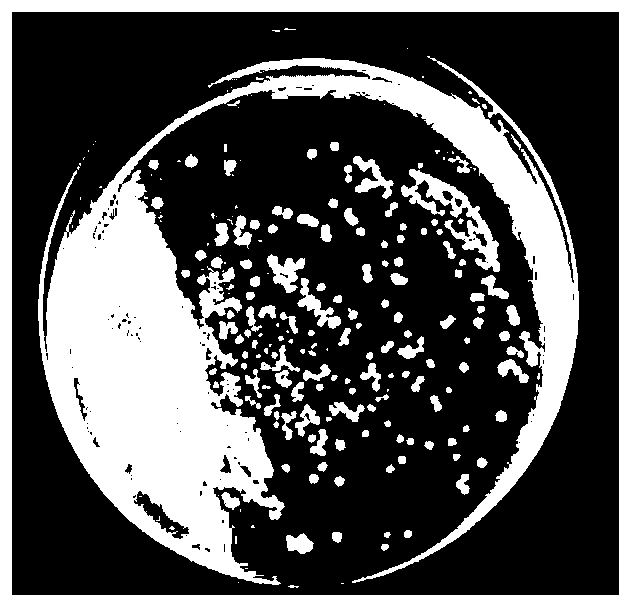

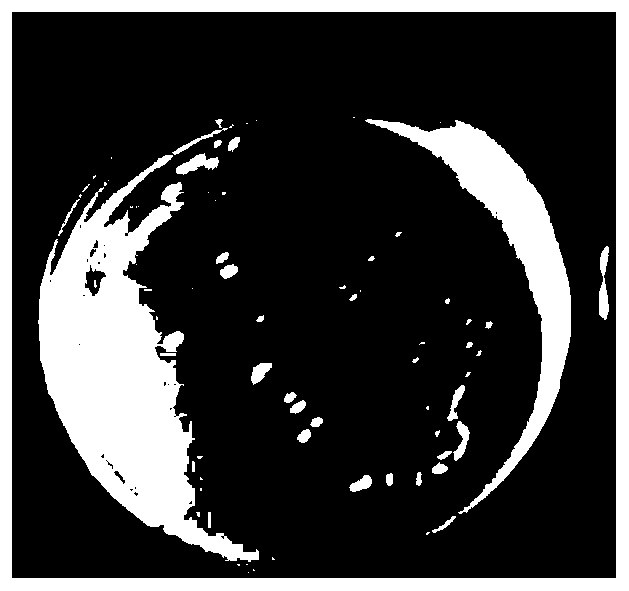

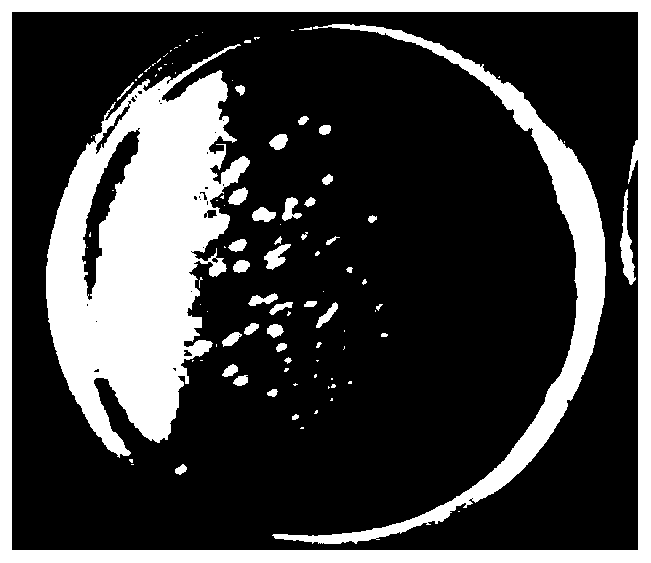

Image

Examples

Embodiment 1

[0026] The shells are ultrasonically cleaned by an ultrasonic cleaning machine, soaked in sodium hydroxide solution, washed with distilled water, dried in a blast drying oven, and then dried in a multi-functional pulverizer for crushing, and finally placed in a horse The furnace was heated to 1100°C at a rate of 10°C / min for calcination for 4 hours, and the shell powder carrier was obtained by grinding with a mortar. Weigh 13g of titanium sulfate, put it in a three-necked flask, add 15ml of distilled water to dissolve, stir at 95°C until a milky white precipitate is produced, adjust the pH value to 9, stir and disperse 12g of shell powder solution magnetically for 30min, then add it to the three-necked flask; weigh 24g of Zn (NO 3 ) 2. 6H 2 After O, the Zn(NO 3 ) 2. 6H 2 The O solution was slowly poured into 3% sodium hydroxide solution, stirred and mixed evenly, and the mixed liquid was added dropwise into a three-necked flask, stirred at a constant temperature for 3 hou...

Embodiment 2

[0028] The shells are ultrasonically cleaned by an ultrasonic cleaning machine, soaked in sodium hydroxide solution, washed with distilled water, dried in a blast drying oven, and then dried in a multi-functional pulverizer for crushing, and finally placed in a horse The furnace was heated at a rate of 6 °C / min to 800 °C for 2.5 hours for calcination, and the shell powder carrier was obtained by grinding with a mortar. Weigh 12g of titanium sulfate, put it in a three-necked flask, add 15ml of distilled water to dissolve, stir at a constant temperature of 95°C until a milky white precipitate is produced, adjust the pH value to 8, stir and disperse 12g of shell powder solution magnetically for 30min, then add it to a three-necked flask; weigh 25.6g of Zn(NO 3 ) 2. 6H 2 After O, the Zn(NO 3 ) 2. 6H 2 The O solution was slowly poured into 3% sodium hydroxide solution, stirred and mixed evenly, and the mixed solution was added dropwise into a three-necked flask, stirred at a c...

Embodiment 3

[0030] The shells are ultrasonically cleaned by an ultrasonic cleaning machine, soaked in sodium hydroxide solution, washed with distilled water, dried in a blast drying oven, and then dried in a multi-functional pulverizer for crushing, and finally placed in a horse The furnace was heated at a rate of 6 °C / min to 800 °C for 2.5 hours for calcination, and the shell powder carrier was obtained by grinding with a mortar. Weigh 12g of titanium tetrachloride, put it in a three-necked flask and add 15ml of distilled water to dissolve it, stir at a constant temperature of 95°C until a milky white precipitate is produced, adjust the pH value to 8, stir and disperse 11g of shell powder solution magnetically for 30min, and then add it to the three-necked flask; weigh 27.6 g of Zn(NO 3 ) 2. 6H 2 After O, the Zn(NO 3 ) 2. 6H 2 The O solution was slowly poured into 3% sodium hydroxide solution, stirred and mixed evenly, and the mixed solution was added dropwise into a three-necked fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com