Size-adjustable motor coil winding tool and winding method based on tool

A technology of size and coil, applied in the field of adjustable size motor coil winding tooling, can solve the problems of different base size motors not being universal, complicated coil winding tool shape, long production cycle, etc., to reduce the types of parts, processing The effect of low difficulty and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

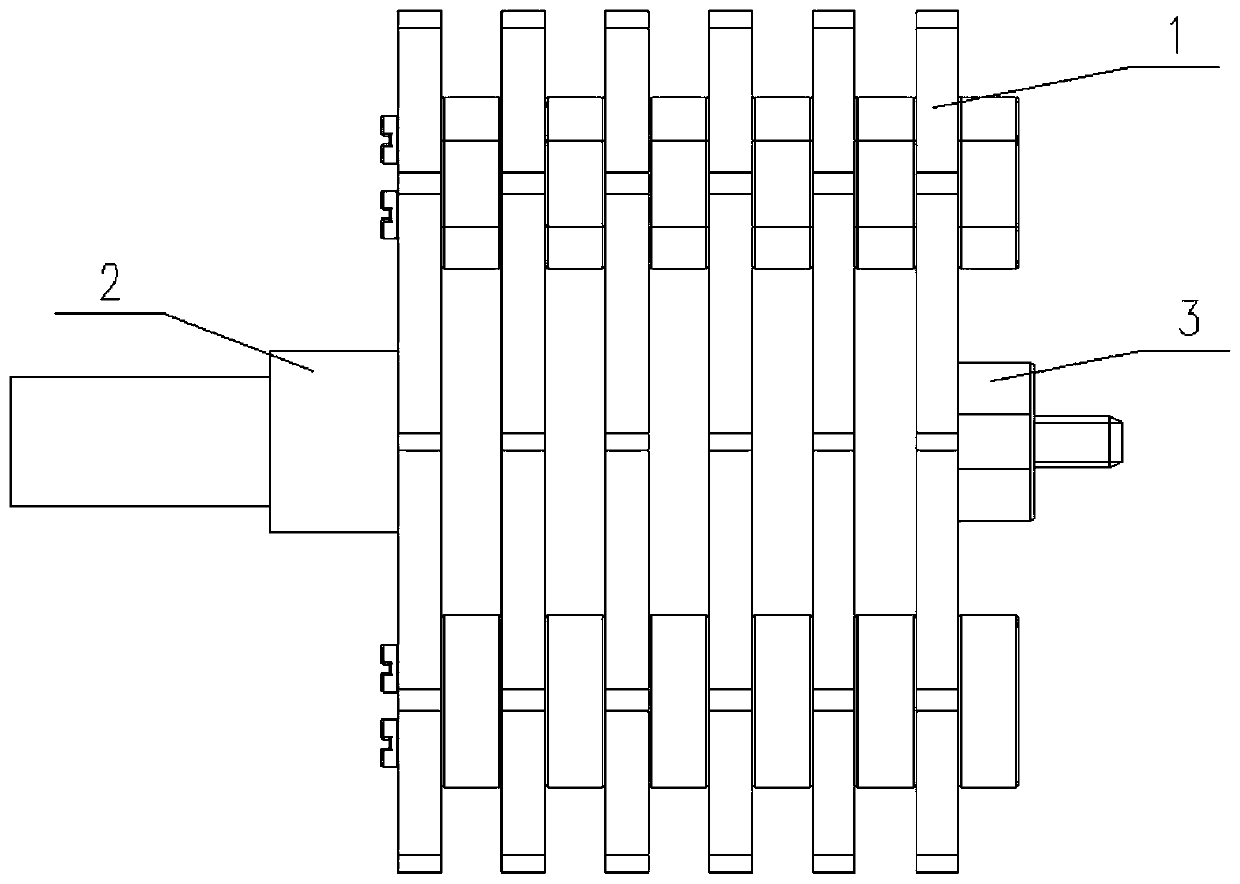

[0053] see figure 1 , the present invention is an adjustable size motor coil winding tool, its structure includes N veneer assemblies 1, positioning mandrel 2 and fastening nut 3.

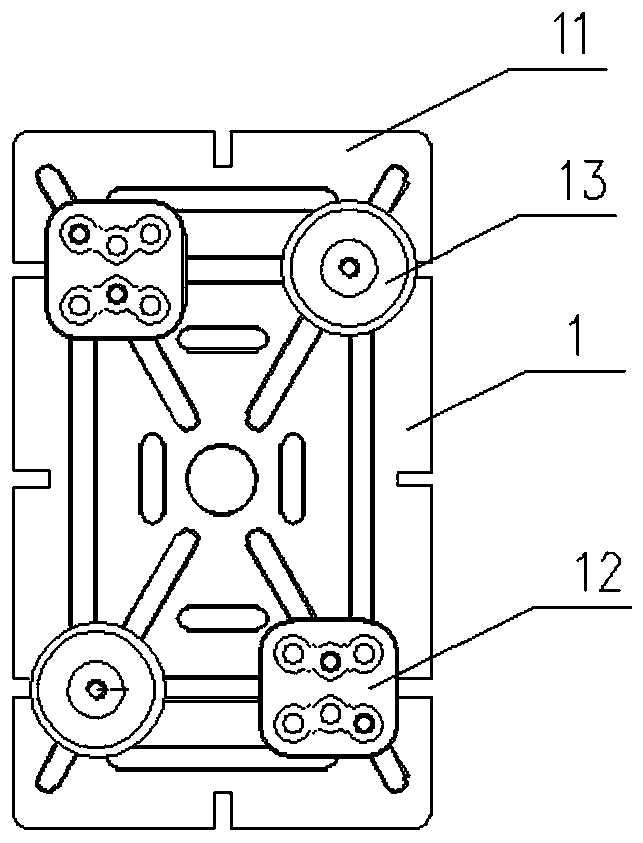

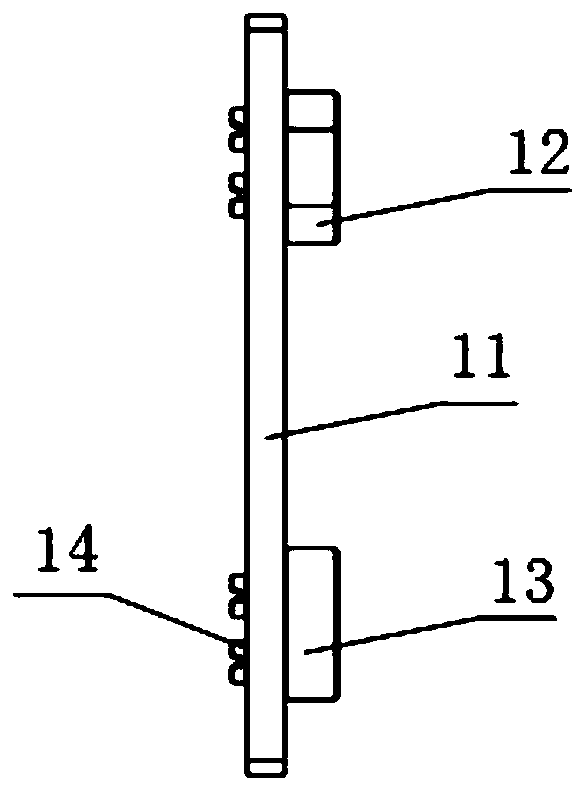

[0054] see figure 2 and image 3 , the above veneer assembly 1 includes a bottom plate 11 , two square sliders 12 , two round sliders 13 and six fastening screws 14 .

[0055] see Figure 4 , the bottom plate 11 is vertically provided with a first through hole 111 and four first elongated holes 112; the four outer end center points of the four first elongated holes 112 are defined as four vertices of a first rectangle; the first The center of the through hole 111 and the axes of the four first elongated holes 112 along the length direction correspond to the intersection of the diagonals of the first rectangle and the four line segments separated by two diagon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com