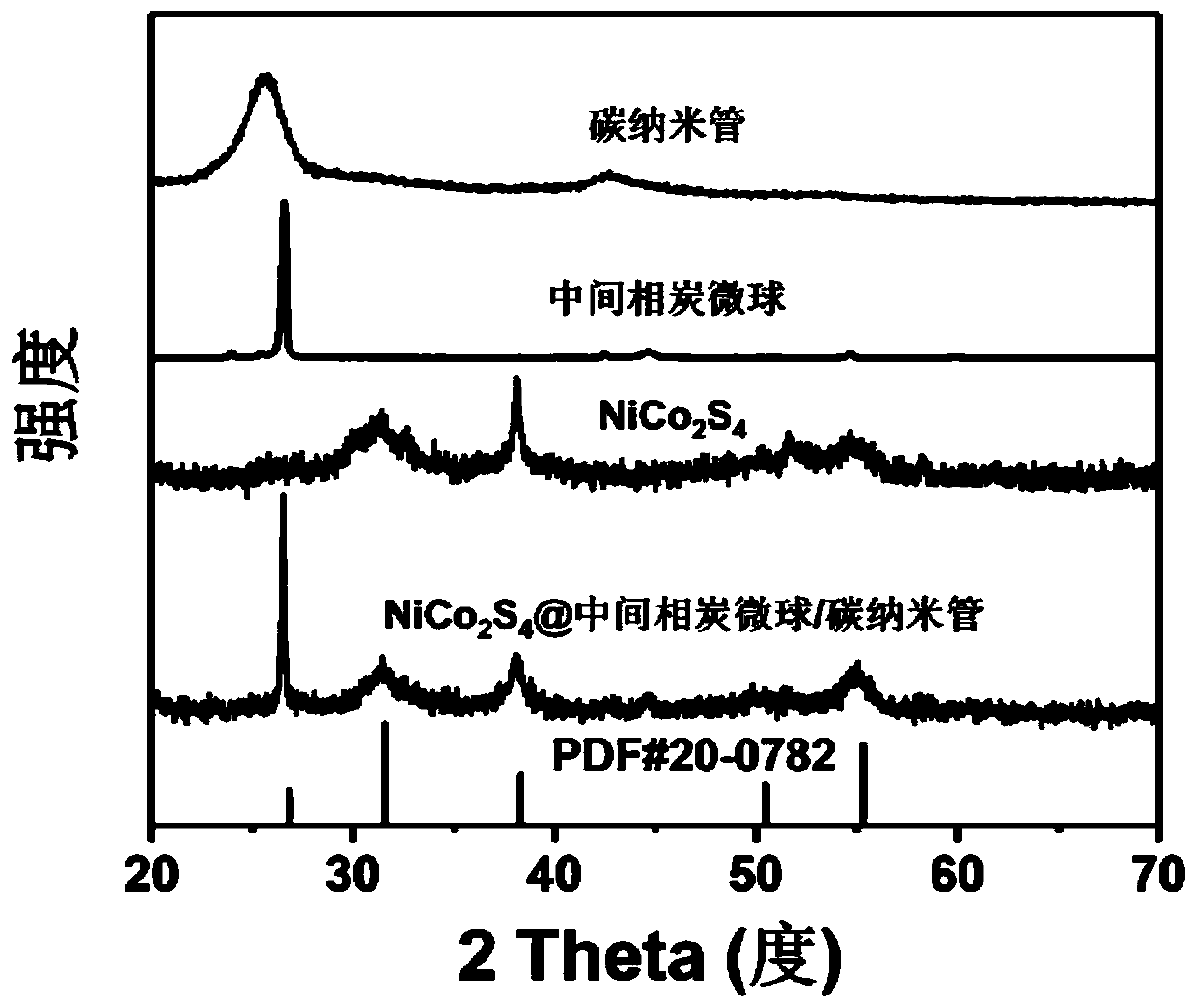

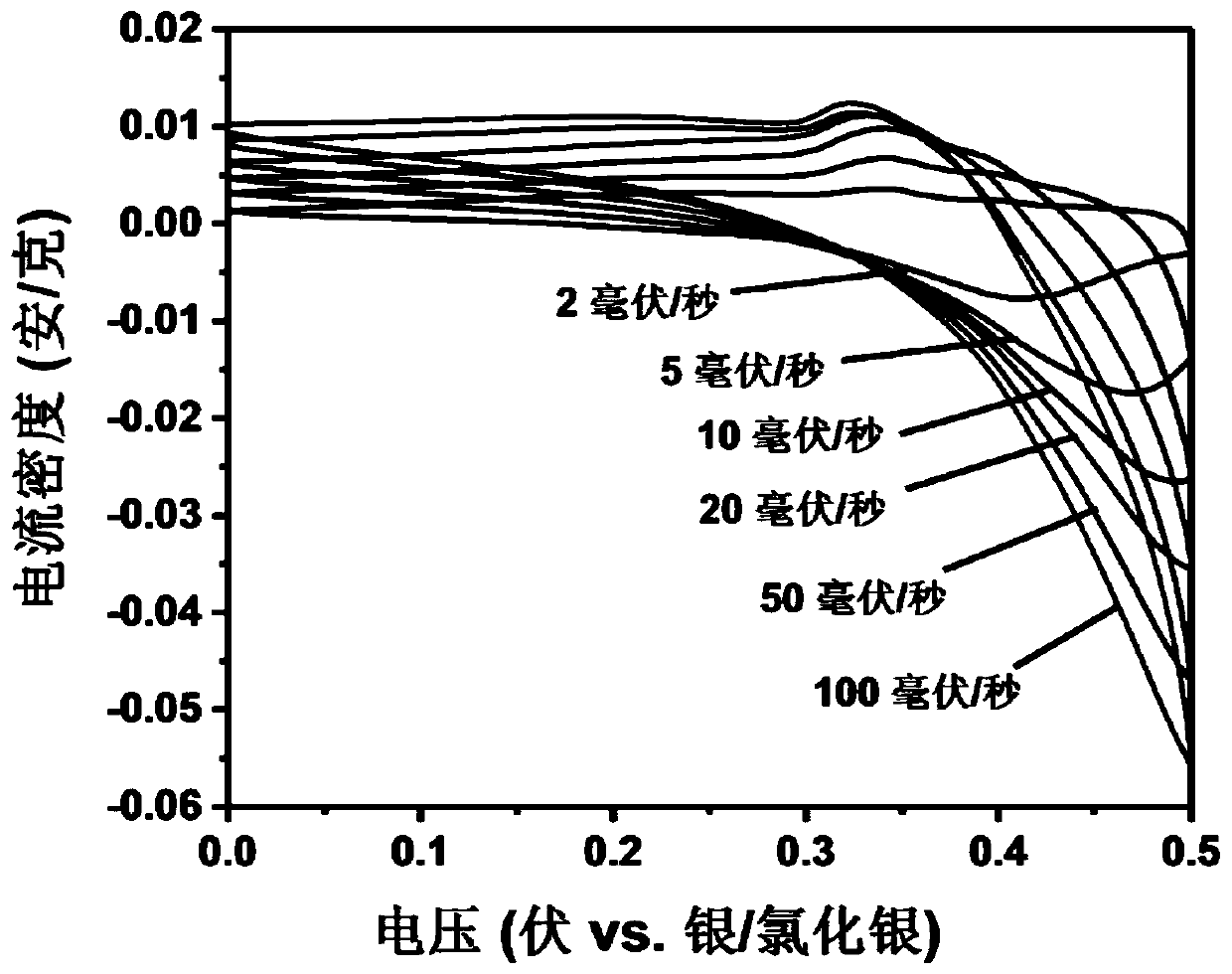

NiCo<2>S<4>@mesocarbon microbead/carbon nanotube composite material and preparation method and application thereof

A technology of mesocarbon microspheres and composite materials, which is applied in the field of NiCo2S4@mesocarbon microspheres/carbon nanotube composites and their preparation, can solve the problems of life cycle limitation, structural instability, short specific capacity, etc. Achieve the effect of improving stability, good cost performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] (1) Ultrasonic dispersion of 121.92 mg carbon spheres and 30.48 mg carbon nanotubes in distilled water for 30 min, followed by Ni 2 + / Co 2+ / urea molar ratio is 1:2:12, add 1.5mmol Ni(NO 3 ) 2 ·6H 2 O, 3mmol Co(NO 3 ) 2 ·6H 2 0, 18mmol urea, stir to obtain a uniform mixed solution;

[0061] (2) Transfer the mixed solution to a hydrothermal reaction kettle and keep it at 120°C for 8 hours;

[0062] (3) Take out the reactant and wash it with deionized water and ethanol. After vacuum drying at 60° C. for 24 hours, dissolve it in distilled water with 1.755 g of sodium sulfide nonahydrate, and stir for 20 minutes;

[0063] (4) Transfer the mixed solution to a hydrothermal reaction kettle for vulcanization, and keep it at 160° C. for 12 hours;

[0064] (5) The reactant was taken out, washed with deionized water and ethanol, and dried in vacuum at 60° C. for 24 hours to obtain the final product.

Embodiment 2

[0066] (1) Ultrasonic dispersion of 137.16 mg carbon spheres and 15.24 mg carbon nanotubes in distilled water for 30 min, followed by Ni 2 + / Co 2+ / urea molar ratio is 1:2:12, add 1.5mmol Ni(NO 3 ) 2 ·6H 2 O, 3mmol Co(NO 3 ) 2 ·6H 2 0, 18mmol urea, stir to obtain a uniform mixed solution;

[0067] (2) Transfer the mixed solution to a hydrothermal reaction kettle and keep it at 120°C for 8 hours;

[0068] (3) Take out the reactant and wash it with deionized water and ethanol, after vacuum drying at 30°C for 24 hours, dissolve it in distilled water with 1.755g of sodium sulfide nonahydrate, and stir for 20 minutes;

[0069] (4) Transfer the mixed solution to a hydrothermal reaction kettle for vulcanization, and keep it at 160° C. for 12 hours;

[0070] (5) The reactant was taken out, washed with deionized water and ethanol, and dried in vacuum at 30° C. for 24 hours to obtain the final product.

Embodiment 3

[0072] (1) Ultrasonic dispersion of 106.68 mg carbon spheres and 45.72 mg carbon nanotubes in distilled water for 30 min, followed by Ni 2 + / Co 2+ / urea molar ratio is 1:2:12, add 1.5mmol Ni(NO 3 ) 2 ·6H 2 O, 3mmol Co(NO 3 ) 2 ·6H 2 0, 18mmol urea, stir to obtain a uniform mixed solution;

[0073] (2) Transfer the mixed solution to a hydrothermal reaction kettle and keep it at 120°C for 8 hours;

[0074] (3) Take out the reactant and wash it with deionized water and ethanol. After vacuum drying at 60° C. for 24 hours, dissolve it in distilled water with 1.755 g of sodium sulfide nonahydrate, and stir for 20 minutes;

[0075] (4) Transfer the mixed solution to a hydrothermal reaction kettle for vulcanization, and keep it at 160° C. for 12 hours;

[0076] (5) The reactant was taken out, washed with deionized water and ethanol, and dried in vacuum at 60° C. for 24 hours to obtain the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com