Gas system optimal scheduling method based on artificial intelligence

A technology for gas system and optimal scheduling, applied in general control system, control/regulation system, comprehensive factory control, etc., can solve problems such as increased gas volume, high fuel consumption of self-generation system, environmental problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

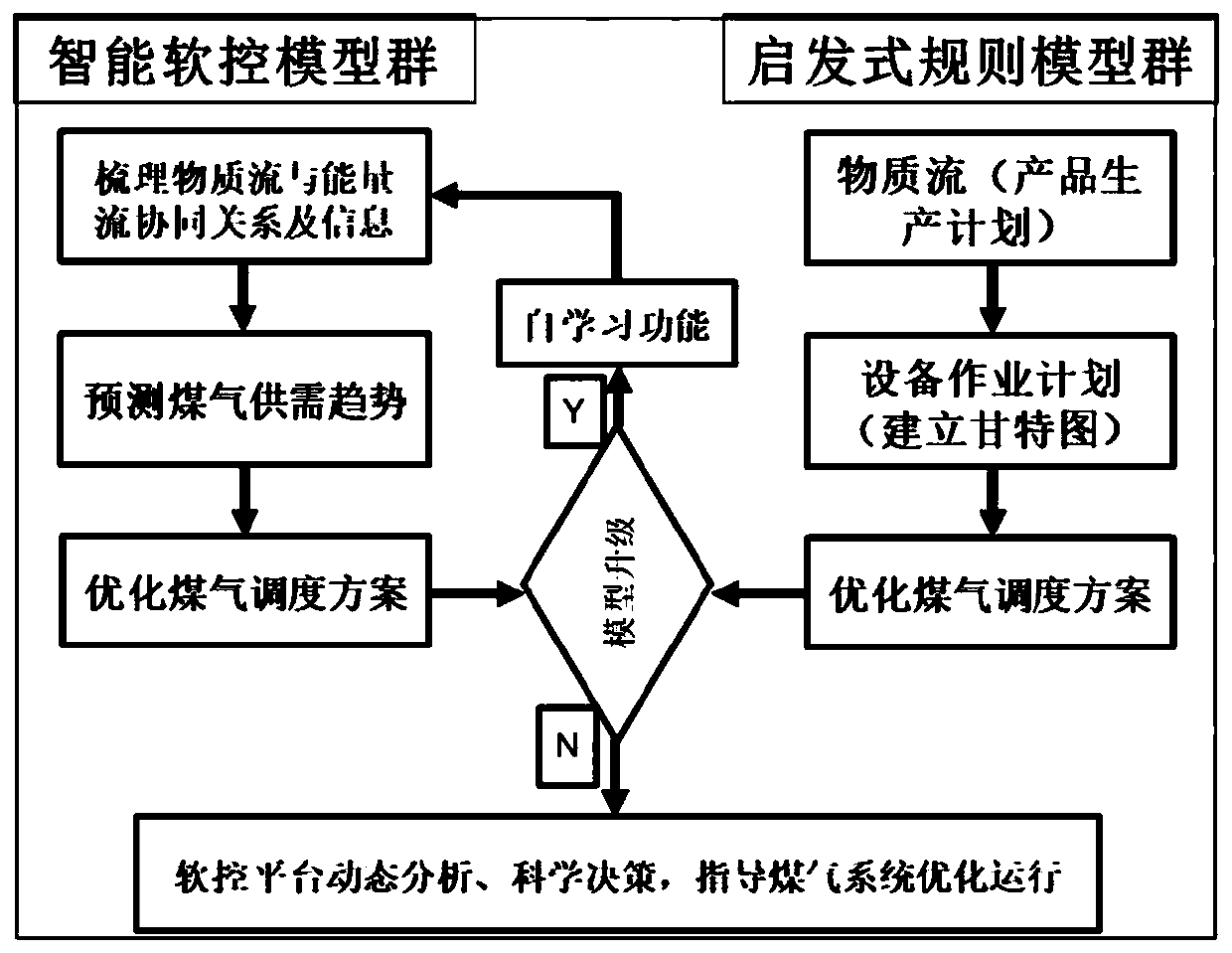

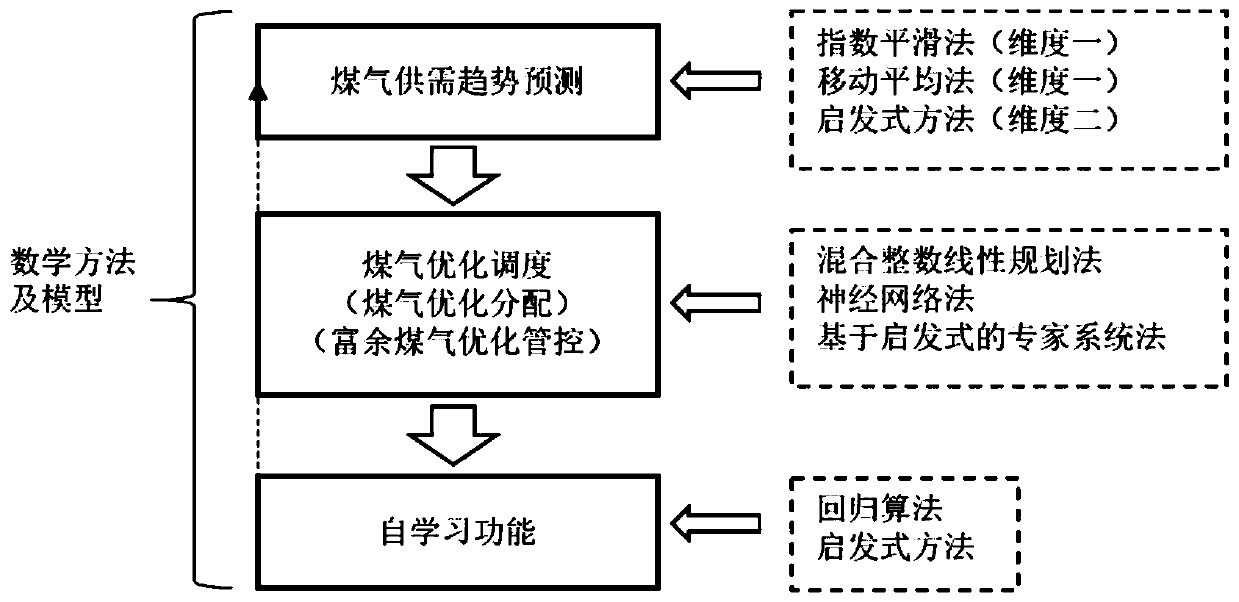

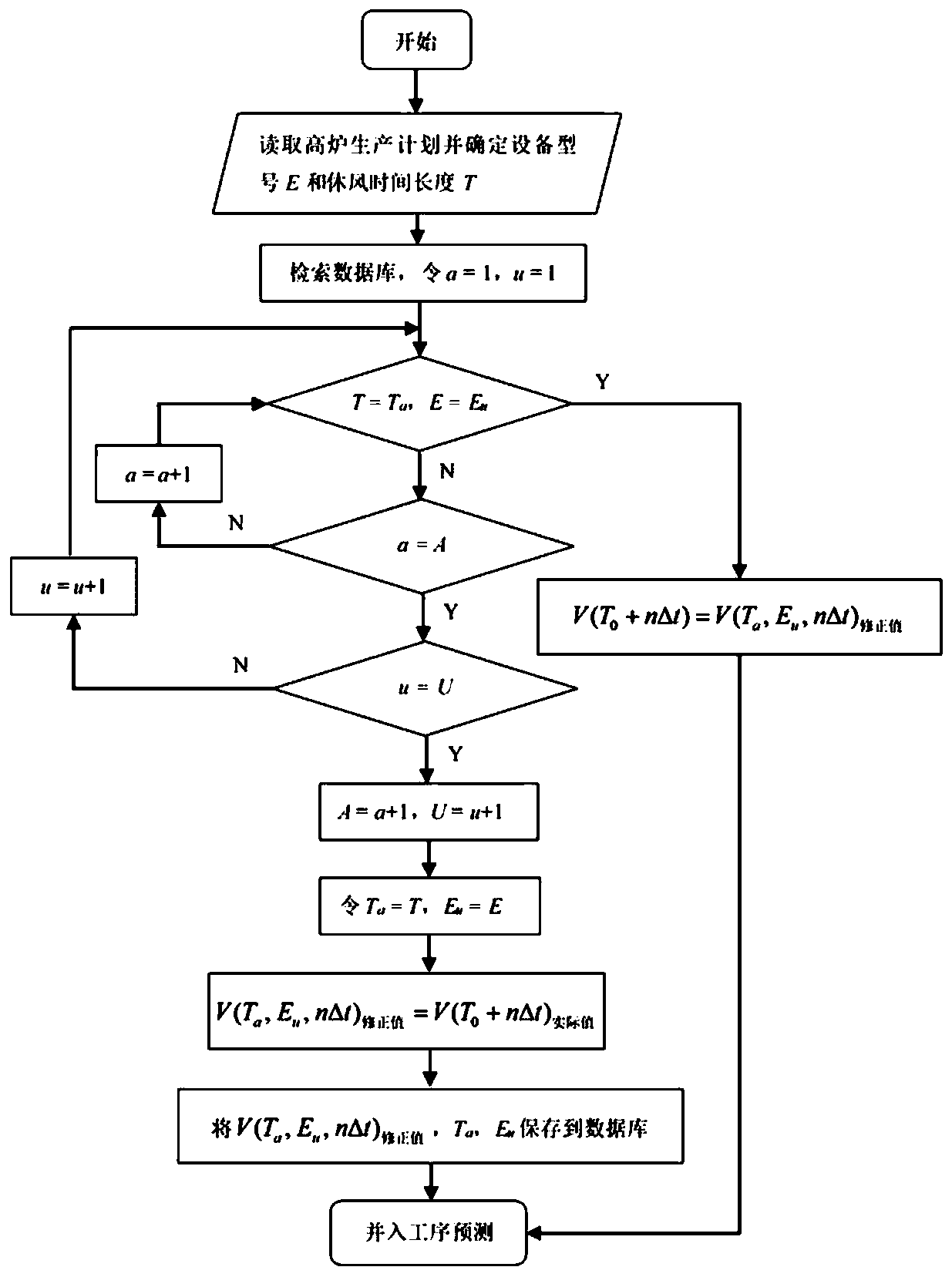

[0091] The specific steps of the present invention are described in detail. The artificial intelligence-based gas system optimization scheduling method includes:

[0092] Step 1. Establish the prediction layer. The first layer is the synergistic relationship between material flow and energy flow in iron and steel enterprises to ensure the stable supply of model basic information and guide the perception of the state of the gas system (prediction and prediction).

[0093] The prediction layer reads the production plan of the enterprise, and according to the continuity of production, the gas production and consumption prediction of the equipment group in the normal production state is calculated using the weight analysis function method; the calculation process is as follows:

[0094]

[0095]

[0096]

[0097] in, is the gas production (consumption) amount of equipment j in process i; P ij is the product output, which is obtained through the production plan; is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com