Urea concentration fault detection method and device, control equipment and storage medium

A technology for urea concentration and fault detection, which is applied to the electronic control, mechanical equipment, and silencer devices of exhaust gas treatment devices, can solve problems such as false alarms and low nitrogen oxide conversion efficiency, and achieve the effect of reducing the risk of false alarms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

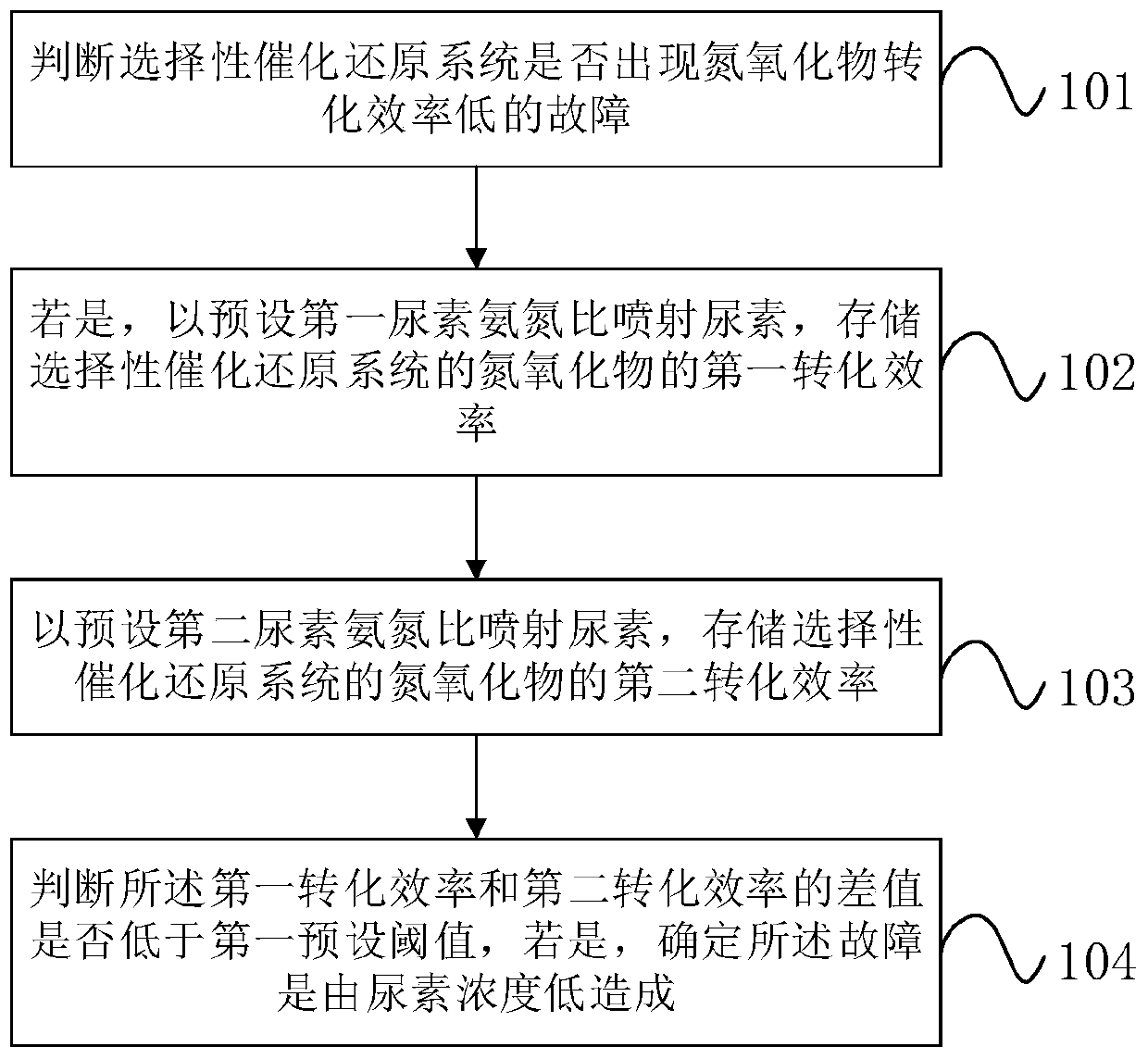

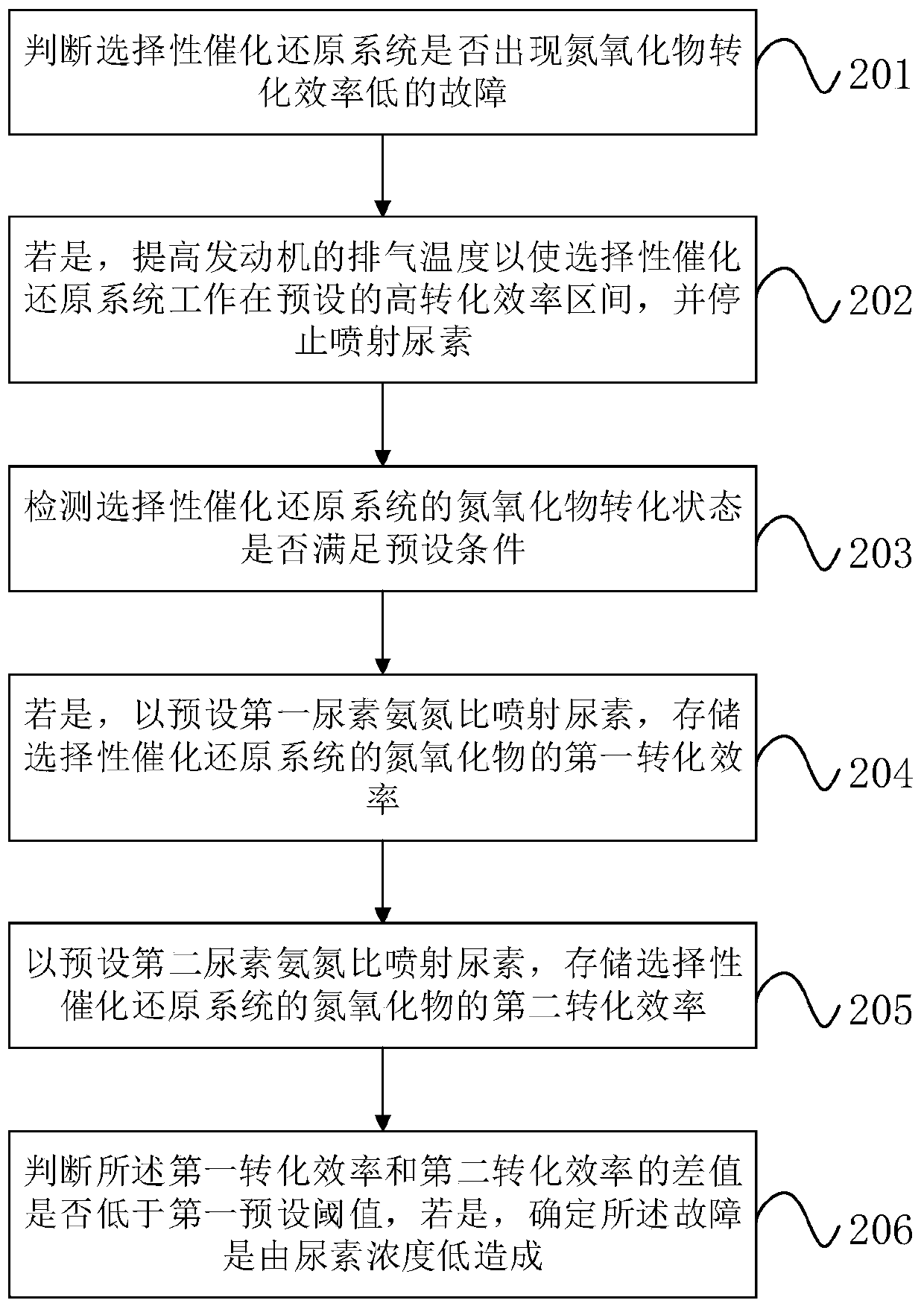

[0046] In order to make the purpose, technical solutions and advantages of the examples of the present invention more clear, the technical solutions in the examples of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the examples of the present invention.

[0047] At first the terms involved in the present invention are explained:

[0048] Selective Catalyst Reduction: (Selective Catalyst Reduction, referred to as SCR) is for the nitrogen oxides NO in diesel vehicle exhaust emissions x A treatment process, that is, under the action of a catalyst, the reducing agent ammonia or urea is injected to reduce the nitrogen oxides NO in the tail gas x reduced to N 2 and H 2 O.

[0049] Ammonia-to-nitrogen ratio: The ratio of the amount of urea injected to the mass of urea required to convert all NOx.

[0050] In the prior art, when a fault with low nitrogen oxide conversion efficiency in the SCR system is usually ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com