Low elastic modulus degradable biomedical metal and its preparation and processing method

A low-elastic-modulus, biomedical technology, applied in functional application-like magnesium alloy materials, low-elastic-modulus degradable biomedical metals and their preparation and processing fields, can solve problems such as human harm and cell death, and achieve low elastic modulus. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

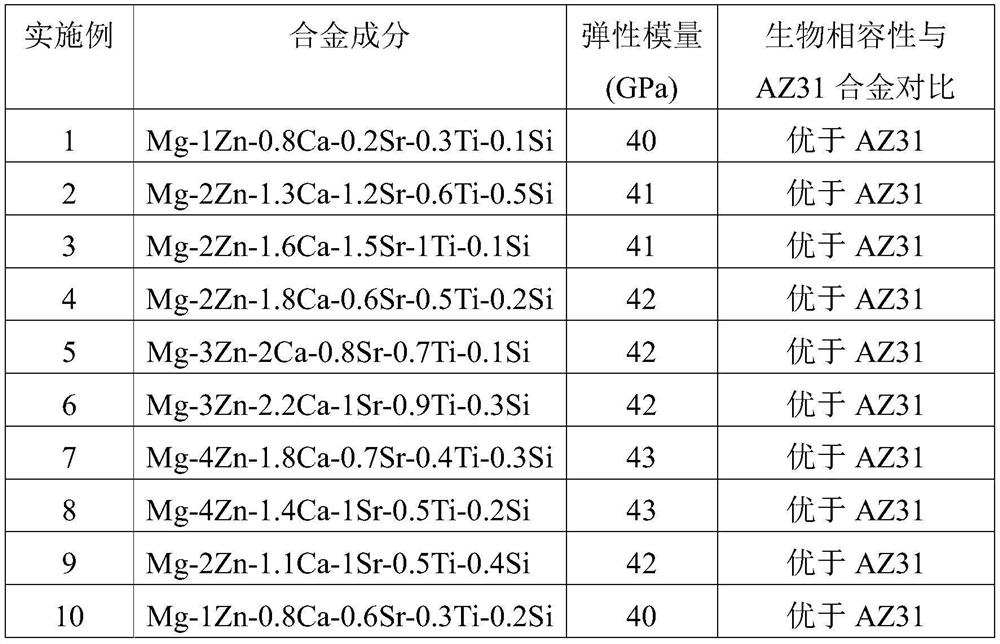

Examples

Embodiment 1

[0042] The basic composition of the alloy is Mg-1Zn-0.8Ca-0.2Sr-0.3Ti-0.1Si (mass percentage). Select high-purity magnesium as the basic material for alloy preparation. The specific requirements are that the content of pure magnesium should reach 5 nines, select Mg-30Ca, Mg-30Sr, and Mg-10Ti master alloys, select simple Si and Zn, and control other impurities below 200ppm. Firstly, heat preservation of pure magnesium in a preheating furnace, the temperature range is controlled at 200°C, and the heat preservation time is 10 minutes to ensure that there is no water vapor on the surface, and at the same time, it is protected by dried argon. At the same time, the temperature of the crucible should be raised to 400°C, the holding time should be controlled at 30 minutes, and argon gas should be introduced at the same time for protection. Put the preheated pure magnesium into the crucible, then raise the temperature to 600°C, keep it warm for 10 minutes, then continue to raise the te...

Embodiment 2

[0047] The basic composition of the alloy is Mg-2Zn-1.3Ca-1.2Sr-0.6Ti-0.5Si (mass percentage). Select high-purity magnesium as the basic material for alloy preparation. The specific requirements are that the content of pure magnesium should reach 5 nines, select Mg-30Ca, Mg-30Sr, and Mg-10Ti master alloys, select simple Si and Zn, and control other impurities below 200ppm. Firstly, heat preservation of pure magnesium in a preheating furnace, the temperature range is controlled at 225°C, and the heat preservation time is 15 minutes to ensure that there is no water vapor on the surface, and at the same time, it is protected by dried argon. At the same time, the temperature of the crucible should be raised to 425°C, the holding time should be controlled at 30 minutes, and argon gas should be introduced at the same time for protection. Put the preheated pure magnesium into the crucible, then raise the temperature to 600°C, keep it warm for 15 minutes, then continue to raise the te...

Embodiment 3

[0052] The basic composition of the alloy is Mg-2Zn-1.6Ca-1.5Sr-1Ti-0.1Si (mass percentage). Select high-purity magnesium as the basic material for alloy preparation. The specific requirements are that the content of pure magnesium should reach 5 nines, select Mg-30Ca, Mg-30Sr, and Mg-10Ti master alloys, select simple Si and Zn, and control other impurities below 200ppm. Firstly, heat preservation of pure magnesium in a preheating furnace, the temperature range is controlled at 250°C, and the heat preservation time is 20 minutes to ensure that there is no water vapor on the surface, and at the same time, it is protected by dried argon. At the same time, the temperature of the crucible should be raised to 450°C, the holding time should be controlled at 30 minutes, and argon gas should be introduced at the same time for protection. Put the preheated pure magnesium into the crucible, then raise the temperature to 600°C, keep it warm for 10 minutes, then continue to raise the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com